Rotor Bike Components Innovates with NX

A history of innovation

Rotor Bike Components is a group of companies specialized in the design and manufacture of parts for medium- and high-performance bicycles. Recognized worldwide, the company has developed four main product lines – plates, potentiometers, cranksets, and bottom brackets – to which they apply maximum innovation in order to compete in a market that is constantly evolving.

With headquarters in Madrid and a presence in 47 countries, the company has branches in Taiwan, the Netherlands, the United States, and a network of more than 5,000 points of sale worldwide. Rotor Bike Components also has two distribution companies: Bikemotiv for Spain, and Rotor Benelux, which caters to Belgium, the Netherlands, and Luxembourg. In 2014, the company closed the year with revenues of €14 million (85 percent of the total coming from exports) and a team of almost 100 employees.

Innovation is in the DNA of Rotor Bike Components. The company’s genesis took place at the School of Aeronautical Engineers of Madrid (Escuela de Ingenieros Aeronáuticos de Madrid), where, in 1995, a group of students conceived a system of connecting rods with revolutionary biomechanical advantages called Rotor System.

Within the business environment, they continued with other innovative releases such as RCK, a frame with a bottom bracket designed specifically to reap the benefits of the Rotor System. Most importantly, the company also created QRings, ovalized chainrings with varying drivetrain resistance to overcome the dead zone and optimize power output during pedaling. This innovation made Rotor Bike Components a benchmark company in the industry internationally.

“Traditionally, the chainrings were round, but we discovered that an oval shape improved performance and decreased muscle fatigue,” explains José Luis Sanz, director of sales at Rotor Bike Components. “We’ve become popular in the market for being able to adjust the plate and give maximum ovality in different positions, depending on where the maximum power is applied when pedaling.”

Cutting-edge technology supports growth

Innovation continues to affect the day-today operations of the company. The interest in offering solutions with the best technology to improve cycling performance is combined with the challenge of producing more than 250,000 components a year with more than 500 different references to cover their road, triathlon, mountain biking and cyclocross supply.

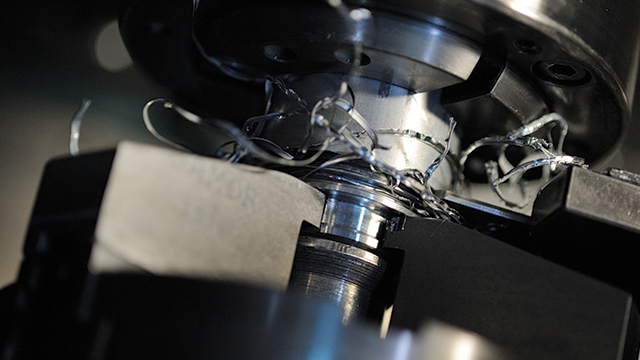

To sustain innovation, it is essential to align the efforts of Rotor Bike Components’ engineering department with manufacturing professionals from their sister company, EDR System, which is a member of the same corporate group. In the 1990s, EDR System became the first firm in Spain to use aluminum and titanium for the manufacture of bicycle parts, and is a technology leader in computer numerical control (CNC) machining.

“We move within a market of very established brands where our competitive weapon is to offer innovation. It’s important to be very agile in order to quickly adapt to change. You have to be very flexible because the average half-life of products is less than 3 years,” notes David Martínez, director of the engineering department at Rotor Bike Components.

Upgrading design technology

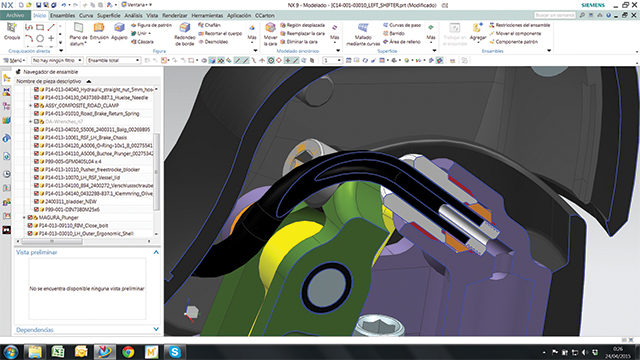

In 2007, the company decided to evolve its computer-aided design (CAD) system, I-deas™ software, to NX™ software from product lifecycle management (PLM) specialist Siemens Digital Industries Software in order to become more competitive. The company faced two key challenges: integrating CAD with computer-aided manufacturing (CAM), and dealing with increasing product complexity. “On one hand, there was no connection between our CAD program and the CAM program of EDR System, and, on the other, the designs were increasingly more complex, especially in addressing assembly, and we needed a tool that was more powerful,” explains Martinez. “We wanted to grow, but without the advanced technology that NX offered us, we couldn’t offer the innovation that would set us apart,” adds Sanz.

After evaluating other solutions the company opted for NX CAD, mainly due to the excellent experience of its sister company, EDR System, which uses NX CAM as a machining solution. NX was introduced to Rotor Bike Components by Análisis y Simulación, a Siemens Digital Industries Software solution partner that shared its extensive knowledge of computer-aided design, engineering and manufacturing (CAD/CAE/CAM) with the company. “We decided to also incorporate NX in our engineering department to take advantage of its design capabilities with multiple advanced features, and ensure total connection with manufacturing processes,” says Sanz.

Maximum collaboration with NX

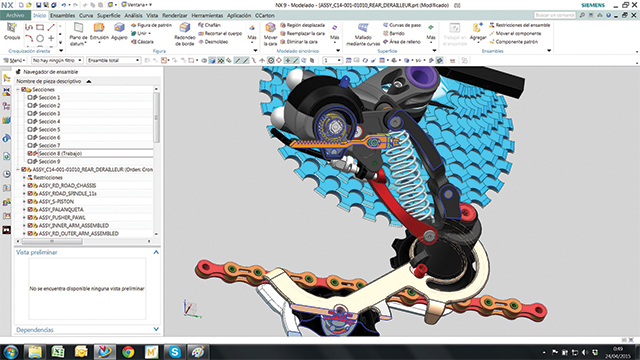

Currently 99 percent of all Rotor Bike Components’ designs are developed with NX CAD. The engineering team has six licenses, and uses the modeling and drafting tools of the software to perform their 3D design, document generation, and drawing plans for parts and assemblies. The design files are sent to EDR Systems for machining and integrated with their NX CAM system. And for new product development, the department of engineering and quality at Rotor Bike Components evaluates the manufactured models for compliance with appropriate regulations.

“Our process not only brings engineering to the work developed with NX, but also includes quality assurance and third-party companies with which we collaborate for various certifications. It also helps to incorporate elements that we do not make ourselves, such as the electronics for the potentiometers,” says Martínez. “It is critical that we can make exchanges without problems in the same file where the modeling, drawing and machining is integrated, in order to easily execute any change that is asked for, or to integrate any file that is sent to us using the extensive import and export capabilities.”

Within the company, a collaborative environment has been created using NX in which the production team also participates by designing the equipment of certain assembly lines, thanks to a floating license hosted on a corporate server. “This option is very interesting, since the production personnel use the tool in a sporadic way,” says Martinez. “It’s also used for making user manuals, for packaging design, for illustrations in patent applications, and other tasks.”

Martinez appreciates the simple, intuitive use of NX that allows for interface personalization and customization. “Análisis y Simulación gave us the proper training in order to take maximum advantage of it in a simple way,” he says.

Synchronous modeling accelerates design

The synchronous modeling tools of NX facilitate modeling, and allow for maximum speed in implementing quick changes, even without a data structure tree. “This feature together with the assurance that we can import any file extension is critical for re-use of models that we already have, especially the regulation files,” Martinez says.

Optimizing engineering with simulation

Engineering also counts on the analysis and simulation capabilities of NX computer-aided engineering (CAE) to optimize their work. “Knowing that NX was modular and that we could integrate different features according to our needs without having to change the system was a determining factor in our decision for NX. The application of the finite element method is going to continue to add more value to our processes, and it’s something that we already have.”

Prepared to offer innovative solutions in record time

The use of NX at Rotor Bike Components has been successful. There is a notable reduction in routine tasks, about 15 percent. This, together with a better connection to key processes such as machining and quality, has allowed for an increase in productivity and a decrease in time-to-market. “Most of our products are on the market in less than one year,” says Sanz. “Thanks to NX we can respond to the immediate needs of various high-competition teams that we sponsor, in some cases fulfilling their needs in just two months. The general consumer also benefits by having access to improvements in the market very quickly,” notes Martínez.

This drive for innovation at Rotor Bike Components has resulted in a larger number of patents. Since 2008, the company has applied for 33 patents, ten of which have been granted, and 18 of which are still being examined. “With NX we can deal with complex designs, especially concerning assemblies, adjusting the appropriate settings for each objective,” says Martinez. “Now we can handle a large number of complex references with ease and with total security.”

NX has been critical in the evolution of the high volume of projects at the company. “This year, in addition to daily production, we are developing 26 projects and we plan to launch a new line of business in which NX has been essential,” Martinez explains.

Rotor Bike Components is aware that the success of the new line of business, as with the rest of their projects, means that the company must continue to innovate and invest in cutting-edge technology as much as they can. “For this reason, we are evaluating the implementation of a PLM solution that allows us to integrate NX with our SAP enterprise resource planning system to streamline and optimize processes,” says Martinez. “Teamcenter software from Siemens Digital Industries Software is one of the options we have in mind.” This addition, along with increased application of NX simulation and analysis, will be key to reducing costs. “Machining is an expensive process because each piece has its own tooling,” Martinez explains. “Removing miscalculations means saving material and time.”

On their journey of innovation, Rotor Bike Components wants to continue using Siemens Digital Industries Software technology. “NX has become a strategic tool that puts us at the forefront and helps us in our day-to-day operations,” says Sanz. “Moreover, working with Siemens Digital Industries Software products strengthens our position in the eyes of customers, and our reputation as a company benefits from the prestige of the Siemens name.”

Learn more about our solutions for consumer products & retail here