NX first CAD software to deliver an immersive experience on new Microsoft Surface devices

Yesterday, I had the honor of joining Microsoft for the launch of the Surface Studio, the Surface Dial and a more powerful Surface Book. As part of this launch, Siemens NX™ software, our flagship solution for integrated computer-aided design, manufacturing and engineering (CAD/CAM/CAE), has been optimized for Surface devices. This offering is revolutionizing how designers and engineers can create a new generation of innovative products.

NX 11 on Surface Studio with the Surface Dial

NX 11 on Surface Studio with the Surface Dial

For more than 20 years, Siemens PLM Software and Microsoft have worked together to provide comprehensive product lifecycle management (PLM) solutions combined with an interoperable, scalable and powerful IT foundation. This collaboration has made it easier for our customers to achieve their business goals quickly and cost effectively across every device, helping to eliminate collaboration barriers and simplify IT complexity.

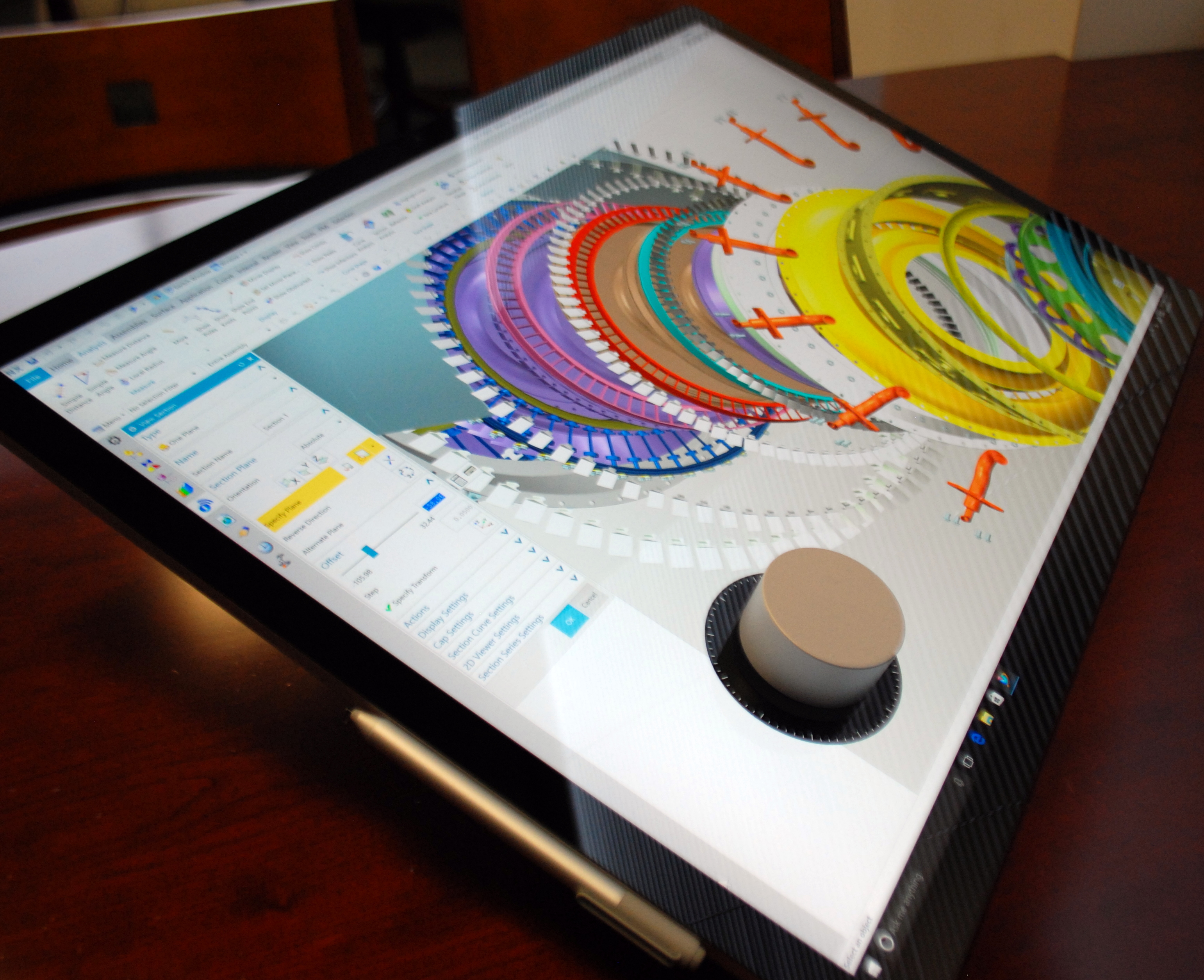

Convergent Modeling in NX 11

Convergent Modeling in NX 11

Optimized for pen and touch interface, NX is specifically tuned for the latest immersive high-resolution displays. We manipulate the world with our hands, so why not interact with and use technology in the same way? With the Surface devices from Microsoft, designers and engineers can realize the full potential of NX in an immersive environment to create a new generation of innovative products. On a large display like Surface Studio, designers can interact very directly with the CAD models in a more natural way. The hinge allows the device to be turned into a powerful digital drafting board with touch, pen and precision input using the new Surface Dial peripheral. This will enable designers to use technology like Convergent Modeling in NX and work with complex, organic shapes in a much more interactive and intuitive way.

Yesterday, we had the opportunity to demonstrate Convergent Modeling on Surface Studio and the new Surface Book—a powerful, versatile laptop. We used scanned data of a human skull to design an implant that has been mapped precisely to the surface of the skull. Convergent Modeling in NX delivers a unified system to simultaneously work with engineered shapes as well as organic shapes. This offers huge saving in terms of time and cost as it eliminates the need for data conversion and reduces the number of steps in the design process. Traditionally, it has been very difficult to achieve a perfect fit for implants requiring many iterations of the design. With Convergent Modeling in NX, we can start interacting with the scanned data directly using precise inputs to control the profile and the thickness of the patch. The precise Surface Dial input mechanism and the level of detail displayed on Surface Studio and Surface Book make it easy to create a complex pattern of the seepage holes that are essential for the proper functioning of the implant.

Design of a cranial implant in NX 11 using Convergent Modeling

Design of a cranial implant in NX 11 using Convergent Modeling

Read more about the new technology from Microsoft: http://news.microsoft.com/2016/10/26/microsoft-introduces-surface-studio-and-the-windows-10-creators-update/#sm.0000wan6w882xe8sqcr16mqrd6zr7

For more information on Convergent Modeling: http://community.plm.automation.siemens.com/t5/NX-Design-Blog/Convergent-Modeling-Shaping-a-Better-Future/ba-p/366635

This is a guest post from Joe Bohman, Vice President of Product Engineering Software (NX), Siemens PLM Software.