Five benefits of PLM for machine builders you can’t afford to ignore

How can engineers delivery highly customized, flexible machines faster and more cost-effectively than they have in the past? And how can they accomplish that while managing global supply chains, evolving customer requirements and shrinking margins?

The answer lies in a comprehensive approach to product lifecycle management (PLM) that goes far beyond basic data management.

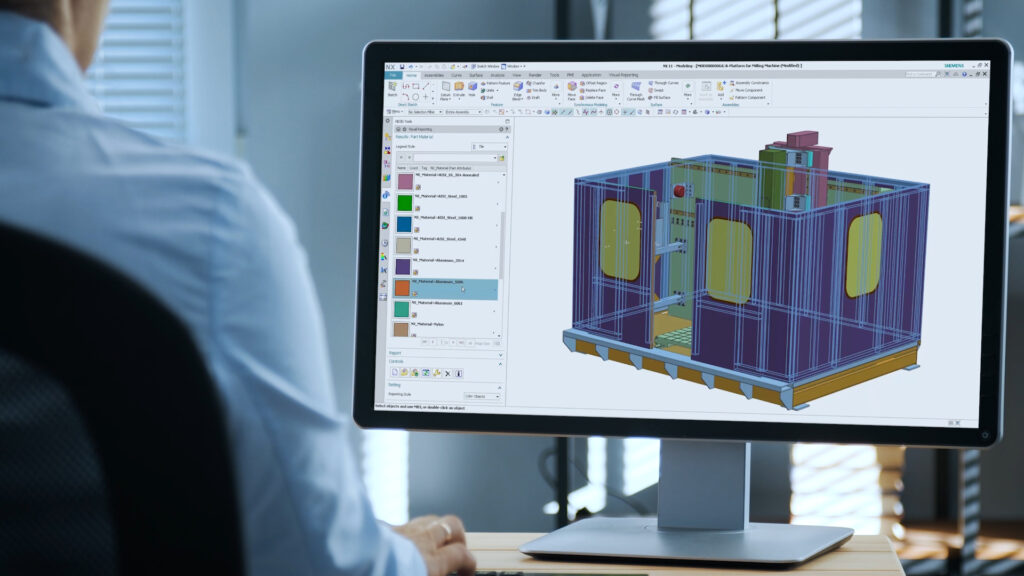

Modern PLM solutions give machine builders the integrated tools they need to compress development timelines, enhance cross-functional collaboration and capture institutional knowledge that would otherwise be lost. PLM for machine builders from Siemens combines requirements-driven project delivery, connected engineering and machine configuration and reuse.

For engineering teams navigating the pressures of engineer-to-order (ETO) and configure-to-order (CTO) environments, PLM represents a fundamental shift from reactive firefighting to proactive, data-driven engineering.

Here are five critical benefits of PLM for machine builders that make it indispensable for any company looking to maintain its competitive edge.

Benefit #1: Faster time-to-market through parallel execution

Traditional new product development and introduction (NPDI) processes follow a sequential workflow: concept development, detailed design, analysis, manufacturing process planning and, finally, production.

This linear approach creates bottlenecks, delays, and missed opportunities for optimization.

PLM fundamentally changes this paradigm by enabling parallel execution of tasks across multidisciplinary teams.

With cloud-based PLM, engineering, manufacturing, procurement and service teams can work simultaneously with access to shared, up-to-date product information and requirements. This managed access to shared information maximizes opportunities to execute key processes in parallel, rather than waiting for sequential handoffs.

Everyone working on the project can ensure requirements are met through requirements-driven project delivery.

The result is time compression achieved not only by reducing cycle times in individual steps but by fundamentally restructuring how teams collaborate.

For machine builders, this means:

- Real-time dashboards that provide transparency into project milestones and help circumvent costly bottlenecks that delay customer deliveries

- Requirements traceability that enables teams to understand how modifications impact timelines before they cascade into late-stage problems

- Faster innovation cycles with better communication, fewer surprises, and more decisions that are “right first time”

According to Siemens research, this parallel execution capability reduces costs and lead times while delivering results that meet specifications on the first iteration. This is a critical advantage when competing against low-cost global competitors.

Benefit #2: Cross-domain collaboration and transparency

Siloed information across departments plagues machine builders everywhere, and it slows down every stage of new product development.

When mechanical engineers, electrical engineers, controls specialists and manufacturing planners work in disconnected systems, the result is duplicated effort, miscommunication and costly, late-stage design changes.

PLM for machine builders provides an integrated, cloud-based platform that lets everyone work from the same plans. A single source of truth enables connected engineering that was previously impossible with legacy systems.

Engineering teams can align on projects at any time, from anywhere, while each department can account for needs upfront or easily communicate changes after the fact.

The technical advantages are substantial:

- Neutral file formats allow anyone to view documents, create rules and leave markups regardless of which CAD system they use

- Workflow and version management track development and order maturity, ensuring teams always work with the most current information

- Integrated project management tools built on industry best practices provide increased transparency into orders through real-time dashboards

This streamlined communication saves time that would otherwise be wasted fixing mistakes in late-stage machine development.

For anyone managing distributed teams, this visibility into product and process information allows additional categories of users across all phases of the product lifecycle to make correct decisions and act quickly.

Benefit #3: Optimized product configuration and BOM management

For machine builders operating in ETO and CTO environments, managing product configurations and bill of materials (BOM) information is one of the most resource-intensive challenges.

Without PLM, engineering teams must manually check every customer order, verify configurations, and recreate similar BOMs from scratch — even when building machines that share 80% with previous projects.

PLM transforms this process through intelligent machine configuration management and BOM reuse capabilities.

By driving the creation of configuration rules used in sales order processing, machine builders can eliminate the need for engineering to check every order. Instead, validated configuration rules ensure only feasible combinations reach the engineering team.

Modular product and manufacturing process structures offer bid flexibility while increasing reuse of tried-and-tested parts and processes. Engineers can reuse BOM information across projects of similar scope with blended ETO/CTO functionality. And integration capabilities allow BOM data to flow seamlessly across enterprise applications, including ERP and MES systems.

This capability is particularly valuable for assemble-to-order (ATO) companies, where PLM provides correct material and component information for any machine configuration. Sales, procurement and production teams can base costs, delivery estimates and plans on accurate, shared information, all of which increases the probability of profitable responses to changing customer requirements.

Machine builders using these capabilities report the ability to source, clone and manage machine structures and CAD documents as business objects, dramatically reducing the time required to configure new variants.

Benefit #4: Knowledge capture and design automation

From tolerance specifications that impact manufacturing costs to assembly sequences that affect production efficiency, engineering knowledge must be stored and easily accessible.

Without a systematic approach to capturing this knowledge, machine builders face constant reinvention of solutions, inconsistent design practices and the loss of critical expertise when experienced engineers retire or leave the organization.

PLM enables systematic knowledge capture and design automation, delivering substantial business benefits.

The system can help machine builders generate automated feedback for designers when certain tolerances or combinations of tolerances are detected, closing the loop between design and manufacturing.

Advanced PLM for machine builders supports rules-based design, automated selection and configuration, and NC program generation.

All these automation capabilities extend from requirements management and initial concept through detailed design, analysis and manufacturing process optimization.

Cloud-based PLM gives users visibility into and control of product and process information, resulting in NPDI that is agile, flexible and fast. For engineering teams, this means focusing on value-adding activities rather than repetitive tasks.

Benefit #5: Closed-loop service intelligence and product improvement

The relationship between machine builders and their customers doesn’t end at delivery. Service and support represent opportunities for significant revenue streams and a source of competitive differentiation.

However, without proper information management, service engineers struggle to access the data they need, and valuable insights from field operations never make it back to the engineering team.

PLM helps service engineers store and retrieve both structured information (parts lists, maintenance procedures, control software updates) and unstructured information (fault reports, field observations, customer feedback).

By building a complete as-maintained history, companies can gain insight into root causes of problems, identify optimum operating conditions, and create engineering change requests based on real-world performance data.

This closed-loop approach delivers faster service response, reduced warranty costs and improved next-generation designs.

The capability to link as-maintained updates with as-installed specifications also provides the required information base for evaluation and planning of upgrade projects — a growing revenue opportunity for many machine builders.

For machine builders, this means product designs continuously improve based on field intelligence rather than assumptions, while service teams can support increasingly complex machines without exponentially increasing headcount.

How do you begin implementing PLM for machine builders?

Digitizing existing processes only provides incremental improvement. True digitalization makes the digital thread of knowledge a proactive agent in driving your business and enables you to initiate or respond to disruptive innovation.

For machine builders eager to evolve and adapt, modern PLM solutions built on secure, scalable platforms with open architecture provide a new way forward.

Over decades of experience with machine builders, leading PLM providers have engineered industry best practices into cloud solutions that support design management, project execution and blended CTO/ETO delivery.

The investment in PLM represents a small step in the digital transformation journey but a big step forward in reducing margins and overdelivering on increasingly complex projects.

Engineering teams can track and manage complex customer requirements with ease, efficiently address change requests and reuse data across similar projects to bring machines to market faster when they implement a comprehensive PLM solution.

Go deeper with PLM for machine builders

Ready to learn how PLM for machine builders from Siemens is changing the way machine builders design, manufacture and service industrial machinery and equipment?

Watch our on-demand webinar to see these capabilities in action and learn how leading machine builders are leveraging PLM to accelerate innovation, improve collaboration and deliver competitive differentiation in today’s demanding market.

Webinar trailer: