Integrated simulation and testing: A better approach to product development

This blog article is co-authored by Tim Yerby and Rajesh Selvaraj Ramaya.

This is the third blog in our Machine Builders’ series. Find the first one here and the second one here.

A quick recap of simulation for machine builders

Machine builders will be the first to tell you they have multiple needs – the need to reduce costs, the need to improve design speed, the need to stay ahead of the competition and more. To meet all these needs, machine builders must embrace a change mindset and open themselves up to the possibility of technological innovation, starting with next-generation simulation.

Most machine builders already use some form of basic simulation to test and prototype their products in a risk-free virtual environment before they produce a physical copy. It makes it easy to understand how attributes like heat, durability, vibrations and other characteristics will impact a machine’s performance, which then feeds machine and sub-component design updates, configurations and product variants.

In short, basic simulation provides immense value by promoting design flexibility while keeping costs low and accelerating the change process. But if this is what basic simulation can do, what does next-generation simulation look like? Let’s take a look.

Integrated simulation and testing explained

The future of simulation can be summarized in one word: Integration. Integrated simulation and testing is an approach that combines virtual testing data with physical testing data to optimize machine performance and design.

What sets integrated simulation and testing apart from basic simulation is that it uses a more precise model of machine attributes and performance predictions, helping businesses make faster, more strategic design and manufacturing decisions.

These precise models are built on a foundation of multiphysics, geometry, usage environment and other characteristics all working in concert within a simulation platform. They create the most accurate modeling conditions, where engineering disciplines can collaborate and understand how physical phenomena, such as thermal, structural, electromagnetic and fluid dynamics, influence one another and thereby influence machine performance.

In turn, a seamless exchange of information is generated between the simulation space and the physical testing environment, helping accelerate product engineering without an increase in cost. An integrated simulation and testing approach thereby accelerates product development, while simultaneously supporting the evaluation of more design options.

The three categories of integrated simulation and testing

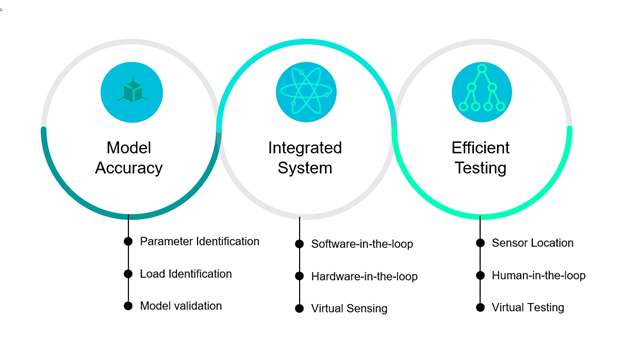

When we break down integrated simulation and testing further, we can assign it into one of three major categories depending on the task at hand.

Model Accuracy: The accuracy of simulation models rely on various physical equations and system constants. Before using simulation to predict system performance, engineers need to verify the model’s accuracy. Physical testing data helps to accurately characterize the system’s physical attributes. Modeling for accuracy, therefore, helps machine builders validate machine models faster, improving design speed.

Integrated System: Modern machines combine mechanical components, electronics and control algorithms. To ensure the proper functioning of control logic, physical testing and simulation modelling must be done together. This tandem approach, which includes hardware-in-the-loop (HiL) and software-in-the-loop (SiL) testing, accelerates product development. Integrated systems, therefore, improve competitive differentiation, as machines with greater accuracy and quality can hit the market sooner.

Efficient Testing: Simulation results inform efficient field-testing strategies. For example, simulations can help plan a pretest by determining the number and placement of sensors. Efficient field testing, therefore, reduces costs, as machine builders can better plan for what attributes and materials to incorporate into product designs while reducing scrap.

While we’ve categorized the collaboration between simulation and testing into three areas, our customers truly benefit from fully integrating system simulation, 3D and testing solutions to address their engineering challenges comprehensively. Now, let’s explore an example of what integrated simulation and testing looks like in practice.

Cutting simulation time by 50 percent: A success story

As a Chinese state-owned manufacturer, Shenyang Machine Tool was challenged by long development times, in addition to stricter regulations surrounding noise and vibrations.

“Machine tool technology has evolved dramatically,” said Zhao Feng, a design engineer in their research and development department. “We have to consider so many aspects [in product development] that a structured and efficient development approach is required.”

Looking for a solution, Shenyang Machine Tool turned toward Siemens’ integrated simulation and testing solution: Simcenter. Simcenter equipped Shenyang Machine tool with a comprehensive simulation and testing environment that could span their entire product development process.

By aligning multidomain system simulation, detailed 3D analysis and test-based engineering in a streamlined development process from concept modeling to physical evaluation, Simcenter solutions helped Shenyang Machine Tool make significant changes to their tool manufacturing process.

Specifically, Simcenter helped Shenyang Machine Tool reduce developmental simulation time by 50 percent, optimize their structures for smoother operations and implement a new methodology for detecting risks earlier in the development cycle.

“Thanks to Simcenter solutions, we can complete all simulations for a component in about two days. Previously, the same process could take up to five days,” said Feng.

As Shenyang’s story alludes to, businesses can overcome a legacy of inefficient and siloed approaches to product engineering by embracing innovative new technologies that digitally transform the manufacturing environment for the better.

These technologies can take many forms, including integrated simulation and testing – a new means for increasing design speed, competitively differentiating within the market and generating cost-savings, all by using a more precise model that combines simulation attributes with physical testing data.

It’s time to take the plunge: learn what integrated simulation and testing can do for you today.