Streamline machine and component design with product lifecycle management for industrial machinery | Webinar recap

Machine builders, industrial OEMs, and component manufacturers face intense pressure to deliver high-quality, reliable products that meet ever-evolving customer demands. To stay competitive, industrial machinery companies need a robust product lifecycle management (PLM) solution that can address industry-specific challenges.

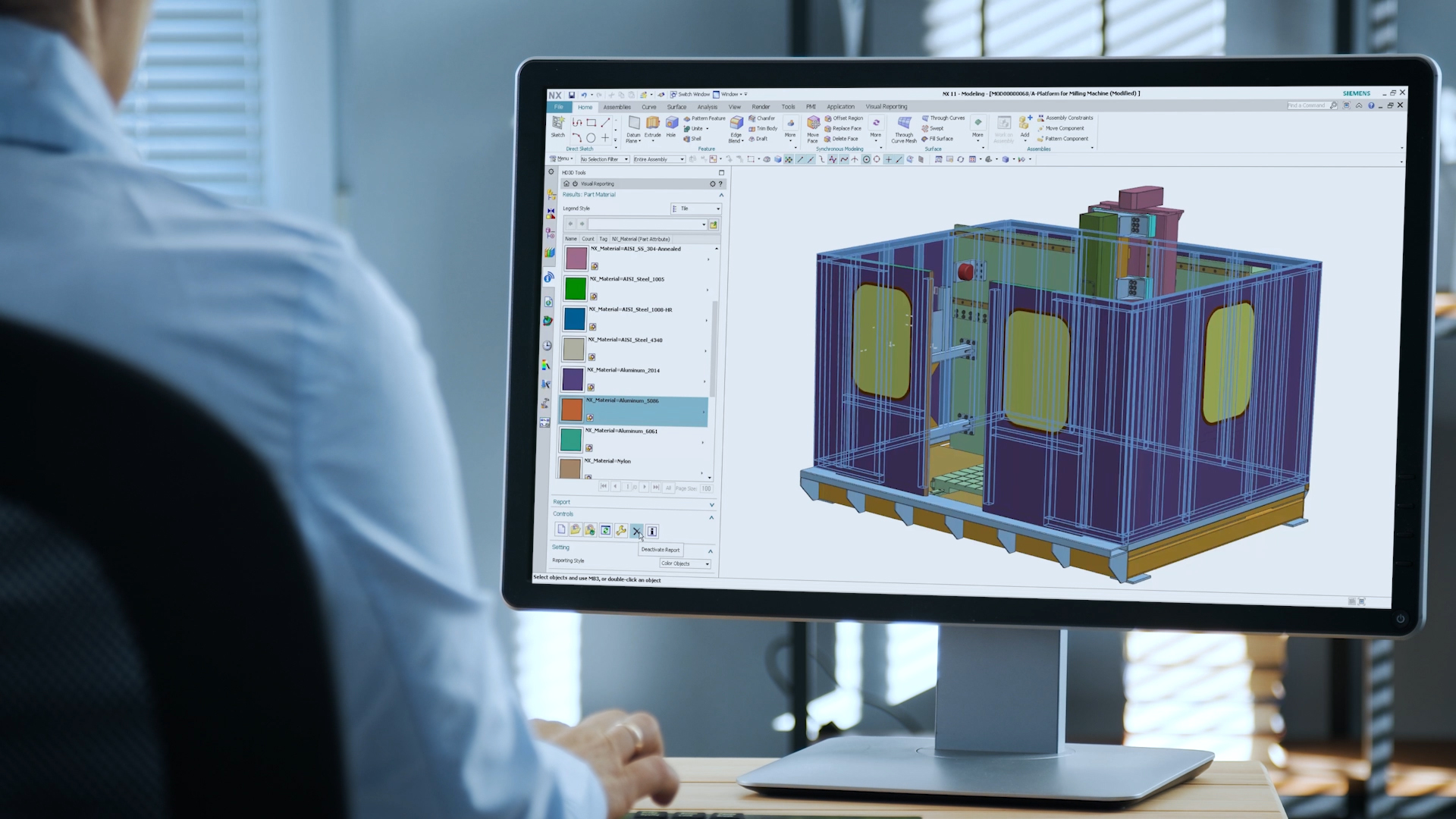

A recent webinar from Siemens Digital Industries Software explored how the PLM for machine builders solution can help streamline the design and development process, enabling more robust and reliable industrial equipment.

Watch the webinar trailer:

A tailored approach to product lifecycle management for industrial machinery

Industrial machinery companies are grappling with a trifecta of market trends – increased global competition, growing product complexity, and more remote and hybrid work models.

To stay ahead, machine builders, OEMs and component manufacturers need a PLM platform that can address these unique industry challenges.

Rather than a one-size-fits-all solution, we’ve pre-configured Teamcenter to address the core processes and challenges faced by industrial machinery companies.”

Chris Pennington, Marketing Manager of Industrial Machinery, Siemens Digital Industries Software

In this webinar, Siemens experts showcased their PLM for machine builders solution – a pre-configured Teamcenter platform designed specifically for the needs of the industrial machinery industry.

Chris Pennington, the Marketing Manager for Industrial Machinery at Siemens, opened the webinar by describing the solution’s intent and giving a broad overview of how it works.

A process-based approach to PLM

This PLM solution’s process-driven foundation fully supports industrial machinery companies’ key business activities, from design and configuration to project delivery.

Efficient machine configuration and reuse with product lifecycle management for industrial machinery

As more manufacturers require customized solutions, machine builders, OEMs and component manufacturers need new ways to streamline product development.

Engineering teams can accomplish this by leveraging product configuration and reuse. PLM for machine builders provides advanced BOM management and cloning tools that make it easy to create new designs based on previous projects.

In this webinar clip, Mr. Pennington highlights this capability and the possibilities it offers.

Machine configuration and reuse

With a single PLM platform, multiple engineering teams can communicate and collaborate more easily and accelerate the design process.

Integrated project and requirements management with product lifecycle management for industrial machinery

Machine project delays and cost overruns often get attributed to inefficient project planning and execution.

PLM for machine builders addresses this challenge by providing a single, connected platform for managing project milestones, customer requirements, and design data.

This gives users quick and easy access to up-to-date information on project deliverables, risks and more. Chris Pennington describes how it works in this webinar clip.

Project and requirements management

Integrating project, requirements, and design data into your PLM solution helps industrial machinery companies deliver on time and within budget while also maintaining compliance with customer specifications.

Streamlining industrial machinery with a tailored PLM solution

As the industrial machinery market continues to evolve, machine builders, OEMs and component manufacturers are going to need a PLM solution that can keep pace with the unique challenges they face.

PLM for machine builders provides a pre-configured, cloud-based platform designed to address the core processes and requirements of this industry.

By integrating core capabilities, enabling efficient data reuse, and streamlining collaboration, this solution can help machine builders improve efficiency, reduce time-to-market, and better serve their customers.

To learn more about how Siemens’ PLM for Machine Builders can benefit your organization, watch the full webinar now.