Product development stages for component manufacturers: Get to market faster

Component manufacturers are feeling the weight of increasingly complex customer requirements, new government regulations and unpredictable supply chains all at once.

New products account for 50 percent of annual revenue for component and equipment manufacturers, which is why it’s so critical for companies to accelerate the product development stages.

Introducing innovative products quickly without jeopardizing product quality continues to be a heavy burden. A zero-sum relationship between product development speed and product quality is not acceptable.

Unfortunately, processes can get bogged down by more complex product requirements because of increased automation, smart capabilities and other changes being driven by Industry 4.0.

Stricter sustainability requirements and targets force companies to evaluate new materials and parts for carbon footprint, energy consumption and more. Companies can find themselves paying tremendous costs — financially or reputationally — for getting sustainable accounting and tracing wrong.

All of this is driving changes to an increasingly complex supply chain, and ultimately, slowing down product development.

But companies can adapt and accelerate their product development stages. Digitalization can make it easier.

More specifically, Accelerated Product Introduction solutions from Siemens.

The Accelerated Product Introduction difference

Match the next-generation approach and processes with the best next-generation tools.

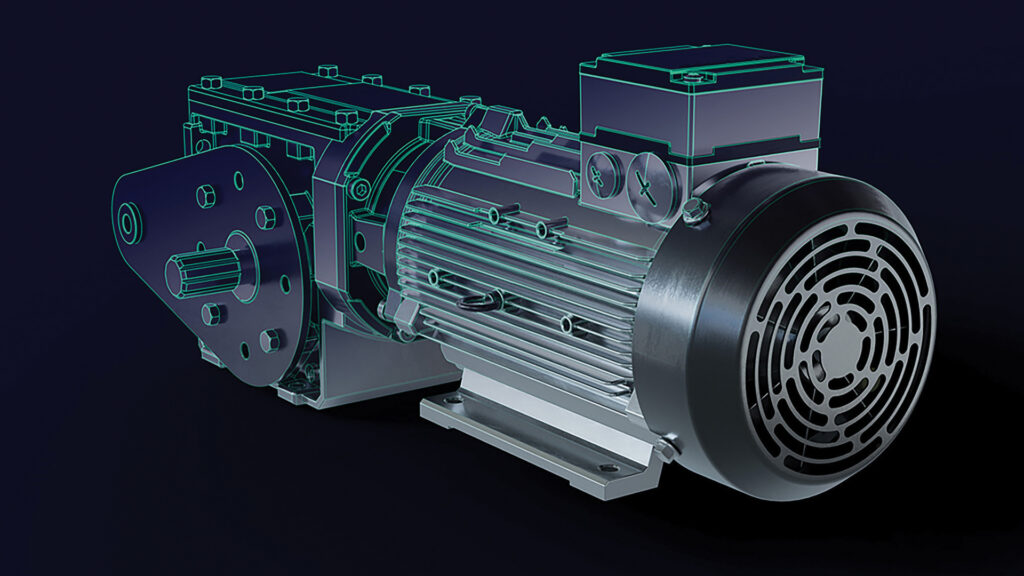

With Accelerated Product Introduction, part of the Siemens Xcelerator portfolio of software, hardware and services, component manufacturers can implement transparent changes and configuration management systems to create a comprehensive digital twin.

The digital twin is a holistic 3D mockup of a component. With that 3D mockup, you can link upstream and downstream engineering systems to guarantee that requirements and orders are visible and traceable.

With these integrated manufacturing and quality processes, you will deliver products with greater consistency, reliability and sustainability.

How can you ensure all this valuable and time-sensitive information is communicated in a timely manner?

Accelerated Product Introduction offers the ability to connect with supply chain vendors, distribution network partners and in-field sellers directly with its cloud functionality. With the cloud, what you need to communicate is done so in real-time.

All these factors combined maximize productivity, reduce costly, time-consuming mistakes and accelerate each stage of product development.

Product development with next-generation NPI

How can a next-generation digital solution, like Accelerated Product Introduction from Siemens, help companies mass-produce highly configurable specialized industrial machine components that are on time, within budget, and sufficiently sustainable? It comes down to visibility and flexibility leading to speed and cost-saving.

Next-generation NPI solutions combine multiple digital solutions in a single integrated approach to component and equipment manufacturing.

This holistic approach allows for carbon and cost-tracking throughout the product lifecycle, creating the opportunity for proactive and intentional economic and environmental decision-making from the beginning, in the middle and at the end to avoid any costly rework.

That level of visibility into the small details for the larger audience also leads to less tangible cost benefits as well.

This level of connection and communication across domains, from suppliers to customers, distills a crystal-clear picture of the expectations, needs and wants of all interested stakeholders.

This leads to fewer mistakes, fewer delays and fewer do-overs. Tangibly, this translates to a 13% reduction in production costs.

Build for profit throughout the product development stages

Everybody is looking for ways to ensure the best possible profit margin.

With Accelerated Product Introduction, you can put the cloud-based platform to work, looking at your expenses internally and externally.

The ability to align directly with supply chain vendors will give your company the transparency you need to evaluate material expenditures accurately.

You can also utilize the cloud-based platform to connect with distributors to get your products into global markets quickly and efficiently.

Ensuring quality excellence drives repeat business

The best business is repeat business. Economically, it’s the least expensive to acquire.

But equally important, repeat business shows a level of trust in your products — a level of trust that will be shared, explicitly or implicitly, across your industry.

With Accelerated Product Introduction, you can ensure you’re sending the most reliable and trustworthy products into the world. Product reliability is built into the DNA of Accelerated Product Introduction digital solutions.

With Failure Mode Effective Analysis (FMEA) and fault trees, equipment manufacturers can trace the origins of any problems early in the design process.

You can add failure resistance straight to your product designs with the help of simulation and reliability prediction tools that help identify potential issues in the virtual realm.

How do you meet the moment?

Siemens understands the pressure on component and equipment manufacturers is immense and growing. Product complexity is exploding due to technological innovation and sustainability demands.

But you have a way to fight back — and win. With Accelerated Product Introduction, you have the tools and principles you need to track and communicate everything from costs to carbon emissions to ensure the delivery of products with optimal quality in record time.

Frequently asked questions about product development stages

Q: What are the specific challenges component manufacturers face when integrating accelerated product introduction solutions with their current systems and processes?

A: Integrating accelerated product introduction solutions with existing systems can be challenging for component manufacturers due to the need to align new technologies with legacy systems, manage data consistency, and ensure staff are adequately trained to use new tools and processes effectively. Fortunately, Siemens offers training and support services to ensure a smooth onboarding process for everyone involved.

Q: How does the implementation of a digital twin improve supply chain management and coordination with suppliers?

A: The implementation of a digital twin improves supply chain management by providing real-time insights into production processes, enabling better forecasting, and facilitating more effective coordination with suppliers through enhanced data visibility and communication.

Q: Are there any case studies or examples of companies that have successfully adopted the Siemens accelerated product introduction solutions, and what were their outcomes?

A: There are case studies of companies that have successfully adopted Siemens accelerated product introduction solutions, showcasing outcomes such as reduced time-to-market, increased production efficiency, and improved product quality. These case studies highlight the practical benefits and ROI achieved through the adoption of these advanced manufacturing solutions.