How machine builders can get started with PLM

Product Lifecycle Management (PLM) software is helping machine builders everywhere overcome the challenges their industry currently faces.

Machine builders around the world face headwinds from new market pressures ranging from increased globalization to disrupted supply chains.

Increased demand for more flexible machines has only increased project complexity.

And adding to all of it, the rise in remote work has made collaboration even more difficult.

A PLM solution designed to meet the needs of machine builders can address all of these.

PLM for Machine Builders delivers what’s needed

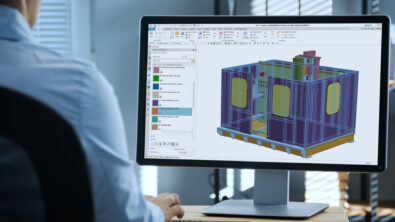

As machine building has evolved and changed, engineers have developed specific processes, best practices, capabilities and workflows to achieve results on time and within budget.

PLM for machine builders embraces how machine builders work and delivers a process-based approach from customer order all the way to delivery.

Tracking the project, product and process information along the way makes the process more efficient and allows for continuous improvement.

Watch this webinar clip and find out how this PLM solution breaks every process into smaller steps.

Get the right capabilities with PLM for Machine Builders

Machine builders manage vast amounts of data designing and building a single industrial machine.

How all this information is managed can be the difference between another fulfilled order and a complex, high-value machine with competitive differentiation and higher customer satisfaction.

A PLM solution with the right features can help machine builders deliver.

Watch this webinar clip and see all the capabilities included in PLM for Machine Builders.

Digitalization with PLM for Machine Builders accelerates innovation

PLM for machine builders incorporates three key areas – project management, machine configuration and blended ETO/CTO tools – to create a connected platform for its users.

When these tools are used together, machine builders and equipment manufacturers can create more predictable, productive machines for their customers.

Better collaboration and automated workflows result in improved efficiency across all projects and faster time to market. Get a brief introduction to the three pillars of PLM for Machine Builders in this short webinar clip.

Go more in-depth with PLM for Machine Builders

This brief introduction to PLM for Machine Builders has only touched on a few of its features and benefits.

The complete on-demand 30-minute webinar takes a closer look at how to get started with PLM, the advantages and disadvantages of using PLM in the cloud, the three pillars of PLM for Machine Builders, and demonstrations of how the software works in multiple scenarios for different users.

Here’s a small teaser of what you can expect.

Learn more about PLM for Machine Builders in this ebook or try a free 30-day trial.