Simplify heavy equipment configuration design and drive profits

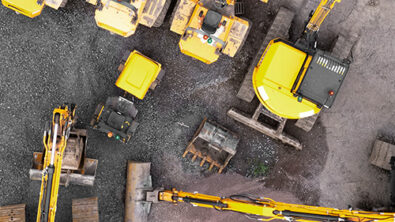

Demand for customized machines is exploding, reshaping the future of heavy equipment design. Configuration design is how heavy equipment leaders are keeping up. From construction sites to agricultural fields, every job has its own demands. Customers want machines tailored to their exact needs and delivered quickly. Meeting this demand, without sacrificing profitability or product quality, requires rethinking how you manage product variability.

Configuration design turns complexity into opportunity—simplifying design processes, maximizing commonality and re-use and ensuring every machine you deliver is high-quality, customized and on time.

The cost of fragmented processes

Today’s heavy equipment manufacturers face growing complexity—from region-specific regulations to custom requirements to the integration of autonomous and connected product capabilities. Yet many continue to manage variability using disconnected tools: spreadsheets on personal drives, siloed CAD and ERP systems and critical knowledge passed informally between teams.

This fragmented approach leads to:

- Engineers hunting across systems for up-to-date configuration data

- Manual corrections to fix misaligned BOMs

- Costly rework when design changes fail to cascade

- Late deliveries caused by poor visibility into product variations

Transform your configuration design process in three key steps

1. Centralize data and processes with a digital backbone

To overcome disconnected systems and data silos, leading manufacturers are adopting solutions like Teamcenter X, a comprehensive PLM platform that serves as a digital backbone. By centralizing configuration design data across engineering, manufacturing, and procurement teams, Teamcenter X enables real-time collaboration and a single source of truth for all product variations.

2. Standardize workflows to scale efficiently

Centralization is just the foundation. To handle growing complexity, manufacturers must standardize configuration design processes across their organization. Using Teamcenter X, you can:

- Separate configuration data from product structure

- Manage configure-to-order (CTO) and engineer-to-order (ETO) workflows within the same system

- Maximize component re-use

- Automatically generate BOMs and 3D visualizations

- Drive consistency across global teams

3. Automate routine tasks and focus on innovation

Once standardized, configuration processes can be automated—saving valuable engineering time and accelerating the design cycle.

Automation capabilities include:

- Automated creation of parts, assemblies and drawings

- Real-time visualization of any product configuration

- Integrated change management across BOMs, CAD, ERP and MES systems

By automating complexity, your teams can deliver high-quality, customized heavy equipment faster—without compromising quality or straining resources.

Position your heavy equipment business for scalable growth

Centralizing and automating configuration design isn’t just a technical upgrade. It’s your path to faster product delivery, higher quality and sustained growth in an increasingly competitive market.

Learn how Teamcenter X can simplify configuration design.

Explore Teamcenter X Cloud PLM

See how BOM management accelerates delivery

Explore digital thread solutions for heavy equipment

Download the BOM and Configuration Management Guide