Smart manufacturing solutions for heavy equipment

Achieve zero-defect manufacturing everywhere

Heavy equipment smart manufacturing is evolving rapidly, and there are more boxes than ever to check to manufacture innovative, customized equipment that satisfies more stringent regulatory and environmental standards. Luckily there are a variety of smart manufacturing solutions available that can speed time-to-market and eliminate costs of late changes within the heavy equipment industry.

As an original equipment manufacturer (OEM), you’re used to working within a framework of strict deadlines, tight margins and low production volume. But new global pressures and product trends require a digital transformation of both processes and technology. While the transition to digitalization is not easy, there are approaches to make it less complicated.

Catch up with Siemens experts in this webinar as they explore the critical role of the smart manufacturing digital thread in enhancing heavy equipment operational efficiency and agility throughout the manufacturing lifecycle:

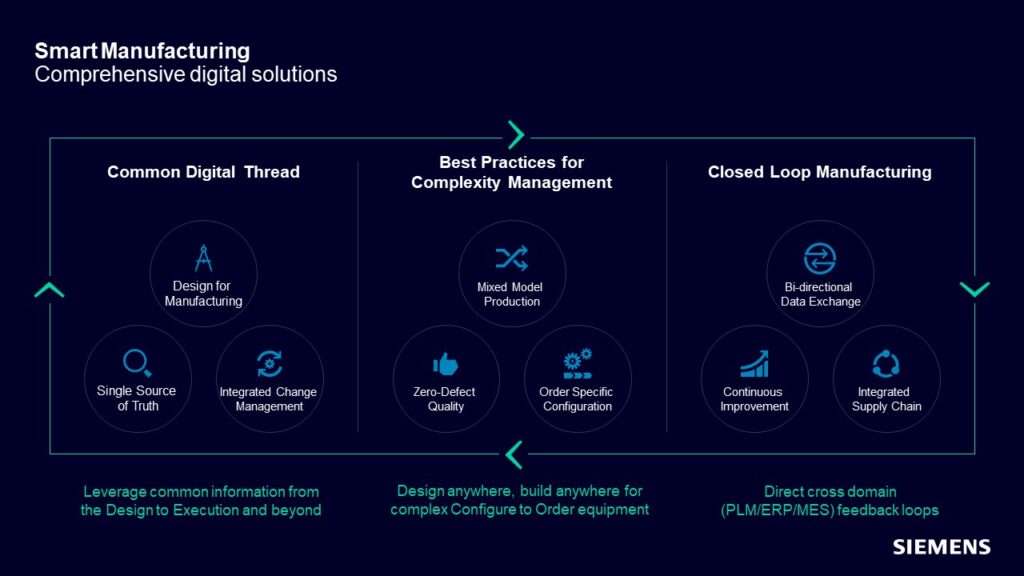

As this image illustrates, there are comprehensive digital solutions to tackle every one of your challenges using smart manufacturing technology:

Let’s dive a little deeper into each of these solutions and how they can help heavy equipment manufacturers achieve zero-defect manufacturing everywhere:

Leverage common information between design and manufacturing

Attempting to manufacture the next generation of machines with numerous configurations and local variants requires mastering a degree of complexity that you cannot handle with traditional, disconnected processes. You cannot manufacture machines that meet today’s requirements for electrification, digitalization, and sustainability without unification, communication and collaboration between your design, engineering and manufacturing domains. With smart manufacturing solutions for heavy equipment, you establish seamless data exchange between design, engineering and manufacturing. With this level of real-time feedback between domains, you can make proactive decisions that save you time and money—less rework, less scrap and faster time to market.

Design anywhere, build anywhere

Whether you’re looking for better data sharing between design, engineering and manufacturing or between different subdomains within manufacturing, the smart manufacturing approach is how you boost your manufacturing key performance indicators (KPIs). By aligning planning, execution and quality, you can institute a collaborative approach to managing complexity across any facility in any location throughout the world. This facilitates greater productivity, flexibility and efficiency and leverages automatically generated part manufacturing best practices and execution insights to improve runs in the future. This closed-loop approach to manufacturing execution yields immediate benefits for manufacturing speed and long-term benefits surrounding process optimization.

Cross-domain feedback loops

Making production excellence a reality relies on visibility and transparency throughout the enterprise. The smart manufacturing approach makes this uniquely painless. It involves the integration of manufacturing operation management (MOM) and manufacturing execution system software with product lifecycle management (PLM) and enterprise resource planning (ERP) systems. This level of system integration ensures that you can access any source of information that can help you further improve productivity, sustainability and consistency. With this degree of closed-loop manufacturing, you can streamline your interactions across every area of your enterprise and even suppliers.

Innovative heavy equipment manufacturing approaches

You know the complications you face. You can sense the limitations of your current processes and solutions. But now you know there’s a better way. With the smart manufacturing for heavy equipment approach, you can see an immediate impact in the present and scalable benefits for the future.

Interested in learning how you can achieve zero defect manufacturing everywhere? Check out these resources below for more information on heavy equipment smart manufacturing:

Resource collection: Manufacturing process planning for heavy equipment

Resource collection: High-performance heavy equipment part manufacturing

Resource collection: Heavy equipment manufacturing operations management

Resource collection: Heavy equipment manufacturing execution systems