Aerospace & Defense – Composite Springback and Manufacturing Planning Trends

Composites in the Aerospace and Defense industry are nothing new, In fact the industry makeup of aircraft, helicopters and spacecraft’s etc. are quite possibly the most important contributors to the growth of the composites industry.

All of this being cosidered, there are still outstanding issues that aerospace companies face when trying to optimize composite materials in order to yield the best benefit and cost savings for their composite structures.

Composite Springback and Manufacturing Planning Research

Recently, A study was conducted to examine issues during the composite manufacturing process and how companies overcome them. The two specific areas during composite manufacturing that were surveyed include composite springback and manufacturing planning.

What is Composite Springback

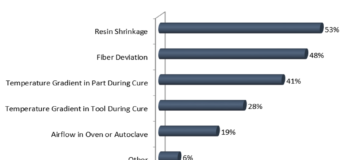

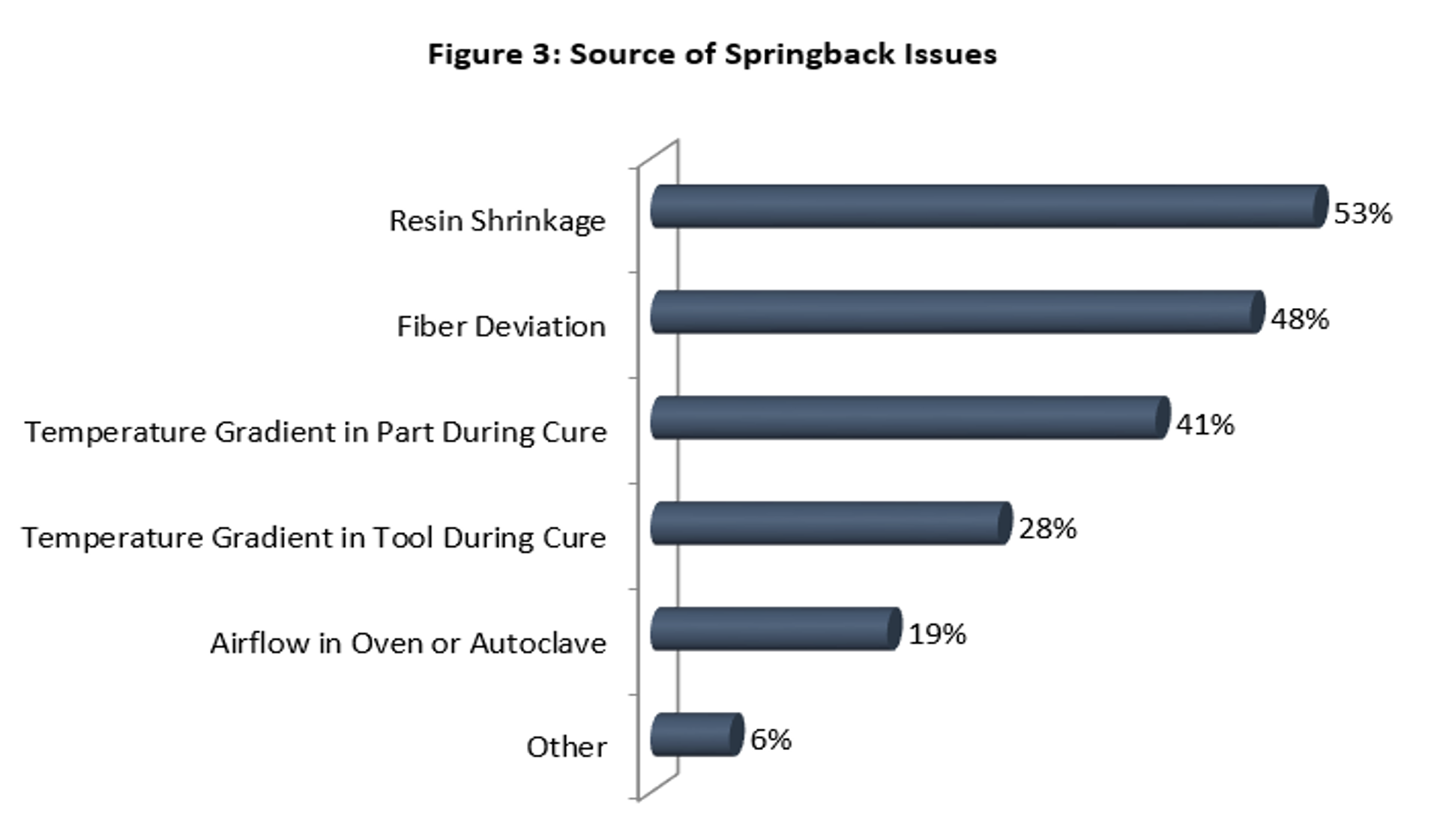

Composite springback refers to the shrinkage of the composite material that occurs during the composite manufacturing process. This distortion often renders the composite design out of tolerance requiring correction or even scrapping of the part. When this happens it can lead to cost and time overruns.

How does Manufacturing Planning Help with Composite Springback

Manufacturing planning is a way to avoid mishaps like composite springback. For companies who have composite manufacturing planning processes in place – it can lead to a higher rate of production of quality, as-design – as-manufacturing composite parts.

The Research Findings

Aerospace and Defense companies utilizing composites were surveyed about their experiences concerning composite springback, how they go about correcting it, and what if any composite manufacturing planning processes they have in place in order to avoid it all together. Their feedback was captured in the resulting Composite Trend in the A&D industry report.

In order to avoid composite springback, recommendations based on this survey suggests:

- Focusing on identifying potential occurrences during the composite design process

- Take advantage of design guidelines

- Consider solutions that offer embedded intelligence to offer guidance and support

- Communicate ply level design data to manufacturing via the engineering model

For more on all of the information and insights collected and provided throughout the “Composite Springback and Manufacturing Planning” survey, access the published report here now.