Article Roundup: Verification as a Flow, Automotive Electromechanical Co-Design & Three Degrees of Freedom in Embedded SW

- Verification As A Flow

- Auto Design Demands Integrated Electromechanical Solution

- Mentor as a maturing Siemens business: 1. Acquisitions

- Three degrees of freedom

- Manage High-Current Traces by Thinking Outside the Box

Verification as a Flow

SemiEngineering

Part 1, Part 2, Part 3

Verification is transforming from a point tool into a multi-level and multi-engine flow. In this series, verification experts, including Mentor’s Mark Olen, discuss the transition of verification to a flow, the challenges this entails, and solutions such as the Portable Stimulus Standard.

Verification is transforming from a point tool into a multi-level and multi-engine flow. In this series, verification experts, including Mentor’s Mark Olen, discuss the transition of verification to a flow, the challenges this entails, and solutions such as the Portable Stimulus Standard.

Auto Design Demands Integrated Electromechanical Solution

EE Times

Disruptions in the automotive market are driving an increase in the electromechanical complexity of modern road cars. Legacy design processes cannot support the inter-disciplinary collaboration required to ensure that the electrical and mechanical systems integrate properly and function as intended. Engineering teams require a new approach: a tightly integrated electrical and mechanical design flow with seamless data transfer and live cross-probing between environments.

Disruptions in the automotive market are driving an increase in the electromechanical complexity of modern road cars. Legacy design processes cannot support the inter-disciplinary collaboration required to ensure that the electrical and mechanical systems integrate properly and function as intended. Engineering teams require a new approach: a tightly integrated electrical and mechanical design flow with seamless data transfer and live cross-probing between environments.

Mentor as a maturing Siemens business: 1. Acquisitions

Tech Design Forum

Siemens’ acquisition of Mentor Graphics has caused many in the industry to wonder how the two companies would merge. At the 55th DAC, Siemens and Mentor were clear that the integration has been smooth, and has even enabled Mentor to pursue key strategic acquisitions. This article examines how Mentor’s latest acquisitions fit in to Siemens’ high-level strategy.

Three degrees of freedom

Embedded Computing Design

Embedded software development used to revolve around balancing the size and speed of the code under development. Bigger algorithms tend to be faster and smaller ones slower. Power, however, has emerged as a third degree of control for embedded software developers, due to software’s increasing influence on the power consumption of embedded devices.

Manage High-Current Traces by Thinking Outside the Box

Printed Circuit Design & Fab

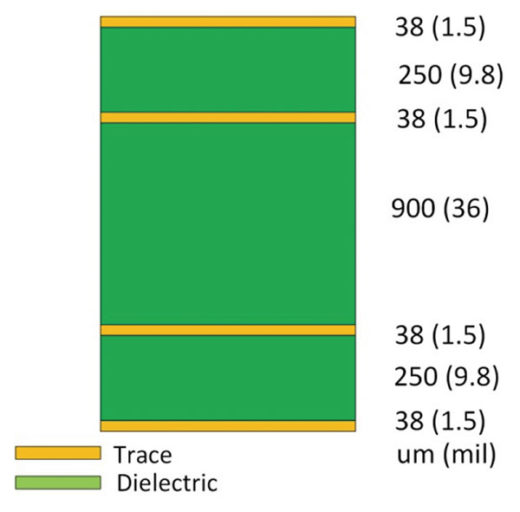

When dealing with power along traces on a PCB, designers often default to increasing the cross-sectional area of the trace to handle the current it is transmitting and to minimize heat. As a result, designers frequently use traces that are too big, eating up valuable area on the board. This article examines alternative strategies for managing current and heat along traces, including variable trace width and the use of copper.

When dealing with power along traces on a PCB, designers often default to increasing the cross-sectional area of the trace to handle the current it is transmitting and to minimize heat. As a result, designers frequently use traces that are too big, eating up valuable area on the board. This article examines alternative strategies for managing current and heat along traces, including variable trace width and the use of copper.