Article Roundup: Verification 3.0, Low-Power Debug Perils, Auto Chip Security, Simulation vs. Digital Twin & Frontloading CFD Analysis

- Get Ready For Verification 3.0

- Solving Six Low-Power Debug Pitfalls

- Built-In Security For Auto Chips

- What’s the Difference Between a Simulation and a Digital Twin?

- Reaping the Benefits of Using Thermal Analysis Earlier in the Design Process

Get Ready For Verification 3.0

SemiEngineering

While verification 1.0 was dominated by simulation and 2.0 added emulation, verification 3.0 features hybrid technologies and distributed computing via the cloud. Verification 3.0, the next-generation verification methodology, has five major pillars including cross process intelligent test bench, hardware and software driven verification, large-scale compute platforms and more. Exactly how quickly verification 3.0 will take over, however, is up for debate.

Solving Six Low-Power Debug Pitfalls

Electronic Design

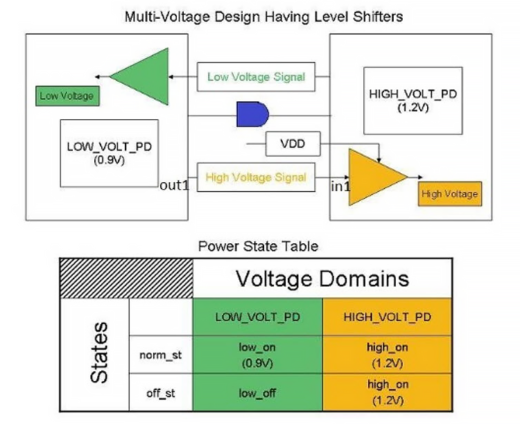

Low-power designs contain sophisticated power management architectures that create complications in the already challenging task of verifying these designs. While the unified power format (UPF) has helped lessen the challenge of power-intent specification, it has had little impact on the verification of these power management architectures. This article provides six common challenges of low-power verification and presents practical solutions to ease the debug process.

Low-power designs contain sophisticated power management architectures that create complications in the already challenging task of verifying these designs. While the unified power format (UPF) has helped lessen the challenge of power-intent specification, it has had little impact on the verification of these power management architectures. This article provides six common challenges of low-power verification and presents practical solutions to ease the debug process.

Built-In Security For Auto Chips

SemiEngineering

Autonomous drive technology necessitates an unparalleled level of security in the chips embedded in a vehicle. The cars of the future will be very similar to networks that exist today, except that the autonomous car network will be much more exposed to the outside world. Securing these networks requires cybersecurity to be embedded in every part of the supply chain and design flow. Luckily, today’s carmakers are ensuring that this happens.

What’s the Difference Between a Simulation and a Digital Twin?

Electronic Design

Digital models have become a nearly ubiquitous part of modern engineering, but can vary in how closely they resemble the physical product. A key differentiator between digital models is the nature of the sensor data they use: is it real or generated? Digital twins use the latest real sensor data to digitally recreate the behavior of a real object, while simulations use generated data. This article further explores this difference and how it influences the ideal applications for each type of digital model.

Digital models have become a nearly ubiquitous part of modern engineering, but can vary in how closely they resemble the physical product. A key differentiator between digital models is the nature of the sensor data they use: is it real or generated? Digital twins use the latest real sensor data to digitally recreate the behavior of a real object, while simulations use generated data. This article further explores this difference and how it influences the ideal applications for each type of digital model.

Reaping the Benefits of Using Thermal Analysis Earlier in the Design Process

Digital Engineering

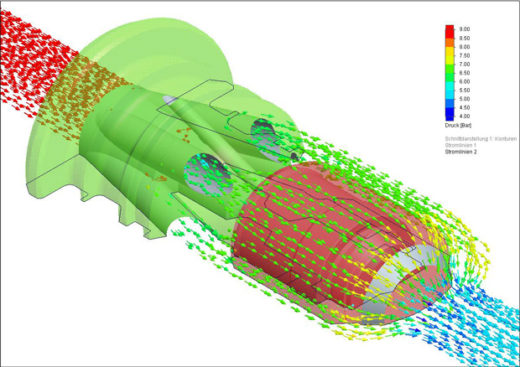

Modern product engineering occurs in multi-discipline design flows that integrate multiple sources of design data. A key facet of these design flows is the introduction of simulations, and particularly CFD analysis, earlier in the design flow through the use of advanced software tools. This article describes how enabling design engineers to perform these complex simulations results in better outcomes on increasingly tight timetables.

Modern product engineering occurs in multi-discipline design flows that integrate multiple sources of design data. A key facet of these design flows is the introduction of simulations, and particularly CFD analysis, earlier in the design flow through the use of advanced software tools. This article describes how enabling design engineers to perform these complex simulations results in better outcomes on increasingly tight timetables.