Engineering deep dive: Technical insights from our multiphysics design optimization webinar

Exploring the power of multiphysics design optimization

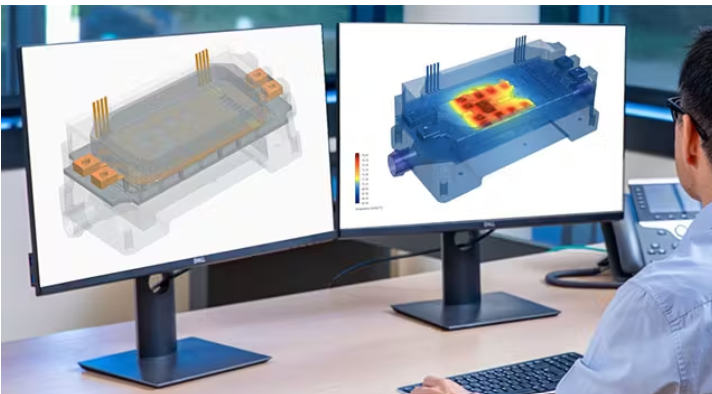

Electric vehicle power modules are getting smaller, hotter, and more complex. But what happens when you need to optimize not just thermal performance, but electrical, hydraulic, and mechanical characteristics simultaneously? Tim Brodofsky from Siemens recently demonstrated a fully automated optimization workflow that’s changing how engineers approach this challenge.

The Sherpa Algorithm: Why your optimization isn’t getting stuck anymore

Traditional optimization methods often trap engineers in local optima – finding a “good enough” solution instead of the best possible one. The Sherpa algorithm within Heeds takes a different approach, intelligently navigating the design space to find global optima even when dealing with thousands of parameter variations.

“During your design exploration, some designs will be solved using the AI simulation prediction, and some will still be the high-fidelity simulation. Sherpa determines when to use each one,” explained Tim.

This hybrid approach significantly reduces optimization time while maintaining precision – a critical advantage when evaluating complex geometries like cold plate pin structures or MOSFET placement configurations.

Beyond temperature: The hidden challenge of parasitic inductance

While thermal management grabs most of the attention, parasitic inductance in SiC power modules creates equally challenging design constraints. The extremely fast switching speeds of SiC MOSFETs amplify parasitic effects, requiring engineers to minimize loop inductance while maintaining thermal performance.

The webinar demonstrated how electromagnetic simulation integrates seamlessly with thermal CFD analysis. This multiphysics approach reveals design trade-offs that single-domain optimization misses entirely – like how MOSFET placement for optimal thermal distribution might inadvertently increase parasitic inductance and switching losses.

Automation without losing design intent

One of the most technically intriguing discussions centered on maintaining design rules during automated optimization. Engineers worry that algorithmic optimization might violate critical constraints, but the Expedition Layout integration preserves essential design rules while exploring parameter variations.

“Within Expedition Layout, users can indeed apply certain constraints,” Tim confirmed, addressing concerns about MOSFET constraint placement. This capability allows the optimization process to respect electrical design requirements while simultaneously optimizing thermal, hydraulic, and mechanical performance.

The cold plate challenge

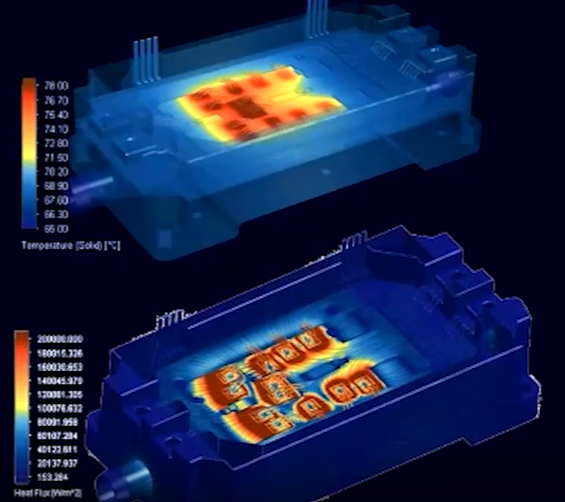

Traditional cold plate design relies heavily on empirical knowledge and conservative safety margins. The demonstrated workflow evaluates hundreds of parameter combinations – pin diameter, pitch, flow patterns, and channel geometries – to achieve the delicate balance between low pressure drop and effective heat dissipation.

The most compelling aspect isn’t just the speed of evaluation, but the multiphysics coupling. The optimization simultaneously considers thermal performance, pressure drop penalties, and mechanical stress from thermal expansion – design interactions that manual approaches often overlook.

Tool integration: Breaking down simulation silos

The technical architecture behind this optimization workflow addresses a persistent industry challenge: data loss and inefficiency when transferring between different simulation tools. The seamless connection between PLM, CAD, CAE, and EDA tools eliminates the traditional “over the wall” design approach.

For teams using non-Siemens tools, the Heeds Connect capability provides integration pathways with various vendor solutions. This flexibility acknowledges the reality of mixed-tool environments while maintaining the benefits of automated multiphysics optimization.

Implementation reality

The technical demonstrations showcased impressive capabilities, but practical implementation requires understanding the underlying simulation framework. The workflow connects thermal CFD analysis, electro-thermal modeling, thermo-mechanical stress analysis, and electromagnetic simulation in a unified optimization loop.

For power electronics engineers, this represents a fundamental shift from sequential analysis to simultaneous multiphysics optimization. The implications extend beyond faster design cycles to entirely new design possibilities that single-domain optimization cannot discover.

The technical depth demonstrated in this webinar represents the cutting edge of power electronics design optimization. From Sherpa algorithm intelligence to seamless tool integration, these capabilities are reshaping how engineers approach complex multiphysics challenges.

The future of power module design isn’t just about better cooling or higher efficiency – it’s about intelligent optimization that discovers solutions human intuition alone cannot find.

Frequently Asked Questions: Power Module Thermal Design

What is the difference between SiC and Silicon power modules in thermal performance?

Silicon Carbide offers an advantage over silicon because, with less resistance to move away from the source (due to increased efficiency), SiC devices can operate at a higher switching frequency. A SiC based system is also more compact and lightweight than a silicon solution, making SiC ideal for high-temperature applications where thermal management is critical.

How do you optimize cold plate design for power modules?

Cold plate optimization involves evaluating parameters like pin diameter, pitch, and flow patterns to achieve low pressure drop while delivering required heat dissipation performance. The webinar demonstrated automated evaluation of hundreds or thousands of parameter variations using smart algorithms.

What are the key thermal challenges in electric vehicle power modules?

Electric vehicles are seeing higher battery voltages to extend the cruising range and improve charging speed, creating a demand for higher output from OBCs and DC-DC converters. This drives the need for advanced thermal management solutions that can handle increased power density in compact packages.

How does multiphysics simulation improve power module design?

Multiphysics simulation enables simultaneous optimization of thermal, electrical, hydraulic, and mechanical characteristics. This approach can reduce design iteration time from months to weeks while ensuring optimal performance across all domains.

What role does AI play in power module thermal optimization?

AI simulation predictors can significantly reduce optimization time by intelligently selecting when to use high-fidelity simulation versus AI prediction models, maintaining accuracy while accelerating the design exploration process.

How do you validate thermal designs in SiC power modules?

Thermal evaluations up to 200 kHz indicated 109 °C peak temperature (below 175 °C datasheet limit) and low switching losses. Validation typically involves both simulation and experimental testing to ensure designs stay within safe operating temperatures.

Conclusion: Transform Your Power Module Design Process

The webinar concluded with a compelling demonstration of how comprehensive multiphysics optimization can revolutionize power module development. With a suite of tools designed to streamline the optimization process, organizations are empowered to digitally transform their operations, ensuring sustainable and efficient solutions for next-generation power electronics.

For those who missed the live session, don’t let this opportunity pass by. Watch the complete 60-minute webinar now to discover how multiphysics design optimization can accelerate your time-to-market, reduce costs, and deliver superior thermal performance in your power module designs.

👉 [Access the Full Webinar Recording Here]

As Siemens continues to innovate and expand its offerings, the engineering and technology community stands to benefit from these advancements, fostering a collaborative environment for growth and development in the power electronics industry.