Blog series: Smart factory insights: Opcenter IPL in action, Part 5

Part 5: Three critical moments reshaping material flow in electronics manufacturing

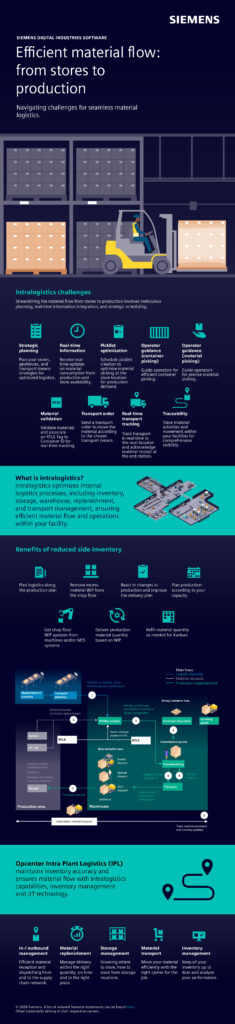

Throughout our series, we’ve examined how Opcenter IPL transforms manufacturing operations, reduces side inventory and creates seamless workflows. Now, let’s focus on three critical moments in the material flow journey that can make or break your operational efficiency.

The Picking Point: Where efficiency begins

As we learned in our exploration of reduced side inventory (Blog 2 link), precise material management starts at the source. ASM Pacific Technology demonstrated a 40% reduction in production bottlenecks by optimizing their picking processes.1 According to SEMI’s latest industry analysis, electronics manufacturers lose an average of 120 productive hours annually to picking errors2.

The picking point represents your first opportunity to:

- Enforce systematic commissioning of the material inventory

- Eliminate selection errors through digital validation

- Reduce material search time by up to 35%

- Ensure accurate inventory tracking

- Optimize and balance staff utilization

Transport Journey: Bridging the gap

Building on our discussion of seamless workflow (Blog 3 link), the transport phase connects storage and production in real-time. IPC’s 2023 manufacturing survey reveals that optimized transport systems can reduce material movement time by up to 45%3.

During this critical moment:

- Materials move with purpose and precision

- Digital tracking maintains real-time visibility

- Smart routing minimizes delays

- Automated systems reduce handling errors

- Automated and manual processes operate seamlessly

This phase directly impacts workflow efficiencies, where manufacturers have seen planning efficiency improvements of up to 50% [1].

The Production Line Interface: Where it all comes together

Connecting to our intralogistics discussion (Blog 1 link), the final moment of truth occurs at the production line. Here, the culmination of optimized material flow creates measurable impact.

Recent industry data shows electronics manufacturers implementing integrated material flow solutions achieve:

- 27% reduction in production line stoppages

- 32% improvement in on-time delivery performance

- 41% decrease in material-related quality issues.4

Transforming moments into momentum

Each of these moments builds upon the last, creating a multiplier effect that transforms manufacturing operations. Want to see exactly how these elements work together to drive efficiency? Our technical implementation guide provides detailed process mapping and optimization frameworks that show you the way forward.