The 80% rule: Why electronics cost control starts in design, not procurement

Electronics engineers face a brutal reality: up to 80% of product cost is set during the design phase, yet most cost optimization efforts focus on procurement negotiations and manufacturing efficiency improvements that can only influence the remaining 20%.

This fundamental misallocation of effort explains why so many electronics companies struggle with margin pressure despite aggressive supply chain management. While procurement teams negotiate fractional percentage improvements on component costs, design decisions made in the first weeks of development lock in cost structures that will persist throughout the product lifecycle.

The companies that achieve sustainable cost advantages understand that effective cost management requires a completely different approach: integrating cost intelligence directly into design workflows rather than treating cost optimization as a downstream procurement activity.

The technical reality of design-driven costs

Modern electronics products contain hundreds or thousands of components, each representing a cost decision that compounds throughout the development process. A mechanical engineer selecting a particular capacitor package might save $0.03 per unit while unknowingly constraining the PCB to a six-layer stackup that adds $2.40 to manufacturing costs. An electrical engineer choosing a specific microcontroller for its processing capabilities might miss that an alternative with identical performance costs 15% less and has better long-term availability.

These micro-decisions accumulate into macro-impacts because electronics cost structures interconnect in complex ways that aren’t visible to individual design decisions. Component selection affects PCB complexity, which influences manufacturing yield rates, which impacts testing requirements, which determines quality control costs. Materials make up 60% of an electronic product’s cost on average, and even the tiniest component can drive that price up significantly.

The challenge intensifies when design teams lock themselves into specific component choices early in development without considering cost implications or alternative sourcing strategies. Many engineers lock themselves into using specific parts early in the design process, leaving little room for cost optimization later on. By the time cost pressures emerge during production planning, the fundamental architecture decisions that drive cost structure are fixed and expensive to change.

The exponential cost of late-stage changes

Industry data reveals why early-stage cost optimization is crucial: the design engineer has the biggest impact on everything that happens downstream, including cost, manufacturability, assembly, testing and sustainability. Changes made during design phases cost a fraction of equivalent modifications during production.

Design changes after production is underway are the absolute costliest, which explains why leading companies have adopted “fail quickly” policies that encourage rapid iteration during design phases when changes remain inexpensive. Each redesign was costing Dana Corporation $3 million until they started using integrated cost management approaches.

The mathematics of late-stage changes are unforgiving. A component substitution that costs $500 to evaluate during design phase might require $50,000 in retooling costs if discovered during production planning, and $500,000 in inventory write-offs plus production delays if identified after manufacturing launch. By addressing the bill of materials early in the design cycle, companies can release products on time while avoiding costly late-stage design changes and quality control problems.

This cost escalation occurs because changes propagate through interconnected systems in complex ways. Modifying a single component might trigger PCB layout revisions, mechanical housing adjustments, software updates, regulatory re-certification and supply chain requalification. The later these cascade effects are discovered, the more expensive they become to resolve.

The carbon cost hidden in design decisions

Electronics cost optimization increasingly includes environmental considerations as regulations tighten and customer requirements evolve. The embodied carbon footprint of new electronic products accounts for 67% ± 15% of total lifetime emissions, instigated by mineral mining, manufacturing and supply chain transportation.

Design-to-source intelligence platform Supplyframe introduced a tool that manufacturers can use to access carbon footprint data for over 300 million different electronic parts, allowing organizations to measure the carbon footprint of components on their bills of materials. This capability enables engineering teams to optimize designs for both cost and environmental impact during the design phase when alternatives remain feasible.

The carbon implications of design decisions extend beyond individual components to system-level architecture choices. Embodied impacts are linear with respect to mass, with a coefficient of 27 kg CO2-eq per kg of product, but lighter products don’t automatically mean lower environmental impact due to the complexity of electronics manufacturing processes.

Research shows that flat-screen TVs were associated with the highest emissions, with about 41 percent of total cumulative emissions, followed by laptops and tablets, flat-screen computer monitors, desktop computers, mobile phones, computer accessories, printers and gaming consoles. Understanding these patterns enables design teams to make informed tradeoffs between functionality, cost and environmental impact early in development when alternatives remain available.

Integrated cost intelligence transforms design workflows

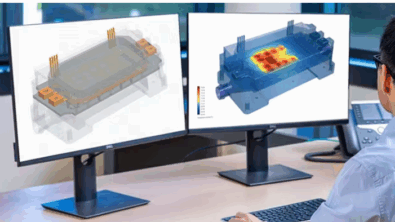

Leading electronics manufacturers are implementing design-to-source intelligence systems that provide real-time cost and sustainability data directly within design environments. The integration between Siemens and Supplyframe enables the Design-to-Source Intelligence platform to be incorporated with electronic systems design software, delivering real-time visibility into global component availability, demand, cost, compliance and associated parametric data.

This integration transforms cost management from reactive procurement activity into proactive design optimization. By providing supply chain intelligence at the point of design, this system facilitates supply chain resilience and empowers engineers to make informed component decisions during the design phase.

Advanced systems go beyond component-level cost data to provide predictive analytics about market trends, supply risk and obsolescence forecasting. Engineers can evaluate not just current component costs but also long-term availability and price stability, enabling design decisions that optimize both immediate cost targets and future manufacturability.

AI technologies can be leveraged to address challenges in PCB design to accelerate time to market, driving down costs, reducing development time and improving the quality of the final product. Machine learning algorithms analyze historical design patterns to suggest cost-optimized component selections and identify potential design risks before they impact schedules or budgets.

The systematic approach to design-driven cost reduction

Electronics companies achieve sustainable cost advantages through systematic integration of cost intelligence into design processes rather than ad-hoc cost reduction initiatives. This requires fundamental changes to design workflows and organizational culture.

- Early-stage cost targeting establishes system-level and component-level cost goals that guide design decisions from project initiation. Rather than discovering cost issues during production planning, teams work within defined cost envelopes that prevent expensive late-stage surprises while maintaining performance and quality requirements.

- Real-time cost feedback provides designers with instant visibility into cost implications of component selections, PCB complexity decisions and manufacturing process choices. This enables optimization during the design process when changes remain inexpensive rather than during production phases when modifications trigger expensive cascade effects.

- Alternative sourcing intelligence presents designers with qualified component alternatives that meet technical specifications while offering better cost, availability or environmental profiles. This prevents lock-in to specific components that might become problematic during production or product lifecycle management.

- Predictive cost analytics leverage machine learning to identify potential cost risks based on market trends, supply chain dynamics and historical design patterns. Teams can proactively address potential issues before they impact production schedules or product profitability.

Technical implementation strategies

Successful cost optimization integration requires specific technical approaches that connect cost intelligence with existing design tools and workflows.

- Component library optimization involves curating preferred component databases that balance technical performance with cost, availability and supply chain considerations. This reduces designer choice complexity while ensuring selections support business objectives.

- Design rule automation implements cost-driven design constraints directly into CAD tools, automatically flagging design decisions that exceed cost targets or create manufacturing risks. This provides immediate feedback without disrupting design creativity or technical innovation.

- Multi-objective optimization enables simultaneous evaluation of cost, performance, environmental impact and manufacturability during design iterations. Designers can explore tradeoff spaces and identify solutions that optimize across multiple business objectives.

Collaborative workflows connect design teams with procurement and manufacturing specialists during design phases, enabling early identification and resolution of potential issues before they become expensive problems.

The competitive imperative

Electronics markets increasingly reward companies that can deliver superior functionality at competitive price points with shorter development cycles. The organizations that achieve this combination understand that cost optimization is a design discipline, not a procurement function.

Design decisions, especially in printed circuit board assembly, have a significant impact on costs for the entire product lifecycle — from initial engineering costs to long-term procurement reliability. Companies that integrate cost intelligence into design processes gain sustainable advantages through better margins, faster time-to-market and more resilient supply chains.

The alternative—continuing to treat cost optimization as a downstream procurement activity—becomes increasingly unsustainable as market pressures intensify and development cycles accelerate. While competitors struggle with cost overruns and late-stage redesigns, companies with integrated design-to-cost approaches deliver profitable products that meet market requirements on schedule.

Your design decisions determine your cost structure. Your cost structure determines your competitive position. The question is whether you’ll optimize both proactively during design, or reactively during crisis management.

Frequently asked questions

What percentage of product cost is actually determined during the design phase? Research shows that up to 80% of product cost is set during the design phase, with the remaining 20% influenced by procurement, manufacturing and operational decisions. This is why early-stage cost optimization delivers far greater impact than downstream cost reduction efforts.

How much do late-stage design changes typically cost compared to early-stage modifications? Late-stage design changes can cost 10-100 times more than equivalent early-stage modifications, depending on the complexity and timing. Changes after production begins are the most expensive, often requiring expensive retooling, inventory write-offs and production delays.

What are design-to-source intelligence systems and how do they help reduce costs? Design-to-source intelligence systems provide real-time cost, availability and compliance data for electronic components directly within design environments. This enables engineers to make cost-optimized component selections during design phases when alternatives remain feasible and inexpensive to implement.

How significant is the carbon footprint impact of electronics design decisions? The embodied carbon footprint of electronic products accounts for 67% ± 15% of total lifetime emissions, primarily from manufacturing processes. Design decisions directly influence these emissions through material selection, manufacturing complexity and product architecture choices.

What’s the ROI timeline for implementing integrated cost management in design workflows? Most organizations see measurable benefits within 6-12 months through reduced late-stage design changes and improved component selection decisions. Long-term benefits include 20-40% improvement in development efficiency and substantially better product margins through optimized cost structures.