Mastering product development: How AI, simulation & sustainability are accelerating product innovation

Product development success hinges on far more than just creative designs — it requires a precise, well-orchestrated process that transforms ideas into market-ready innovations. Today’s leading organizations recognize that structured development approaches are essential for navigating complex challenges around collaboration, sustainability, market dynamics, and strategic growth.

The convergence of product design engineering with artificial intelligence (AI) capabilities and advanced simulation is transforming how teams innovate. By integrating product design engineering best practices with AI‑powered tools and advanced simulation, teams can shorten development cycles, reduce waste, and consistently introduce high quality products to the market with confidence.

In this article, we will explore how Siemen’s integrated solutions are setting new standards for accelerated, intelligent product development.

What is product development?

Product development is the end-to-end process of creating products that meet and exceed customer expectations. The most successful approaches to product development integrate customer insights, engineering excellence, manufacturing feasibility, and quality requirements into a seamless process. This comprehensive approach ensures that every decision at every development stage delivers value while meeting business, regulatory, and sustainability goals.

8 stages of the product development lifecycle

The product development lifecycle consists of eight distinct stages, each driven by specific teams and specialists who bring their expertise to the process.

- Ideation: Brainstorm creative concepts based on user needs and market insights. Generate a broad pool of ideas to explore.

- Idea Screening & Validation: Evaluate concepts against feasibility, business value, and market interest. Engage with potential users to filter through promising ideas.

- Concept Development & Prototyping: Translate ideas into working prototypes—wireframes for software or physical mock-ups. Test these early versions with users to gather essential feedback.

- Business Analysis & Planning: Analyze market demand, cost structure, revenue potential, and viability. Create a business case and roadmap to guide further development.

- Detailed Design & Engineering: Craft full specifications and detailed models using CAD and CAE solutions. Engineers refine form, fit, function, and manufacturability with integrated simulation.

- Testing & Validation: Conduct validation through simulation, lab tests, or limited releases. Use iterative testing to ensure performance, quality, reliability, and regulatory compliance.

- Launch & Commercialization: Move to full-scale production, align marketing and sales efforts, and distribute. Prepare teams and customers with training materials and support plans.

- Post-Launch Feedback & Iteration: Collect real-world user data and continuously refine the product. Improvements or successor products follow the same iterative journey.

Traditional vs next‑generation product development

Traditional product development follows a sequential, waterfall-style flow where each phase, from concept and design through prototyping and production, is completed one after the other. Disciplines like mechanical design, electrical engineering, and manufacturing operate in silos, culminating in costly handoffs and late-stage rework. Heavy reliance on multiple physical prototypes slows iteration cycles, inflates costs, and limits responsiveness to shifts in market demands or regulations.

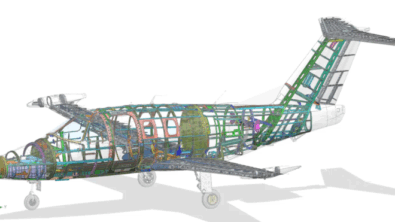

On the other hand, next-generation product development embraces concurrent, multi-disciplinary collaboration and virtual-first methodologies. Mechanical, electrical, software, and manufacturing teams work in parallel, supported by digital platforms that integrate product lifecycle management (PLM), CAD, systems engineering and simulation tools.

This model also leverages advanced simulation to test high-fidelity designs before any physical prototype is built, reducing errors and shortening time-to-market. Generative AI further accelerates ideation and simulation, helping engineers explore optimized solutions at scale.

The result is a transformative shift: instead of isolated, linear processes that stall due to late discoveries and heavy rework, next-gen product development enables agile, integrated workflows. Teams iterate rapidly, apply lessons from virtual testing, and respond more effectively to change, substantially lowering costs, reducing waste, and increasing product innovation

Defining the future of new product development

Today’s smart devices contain millions of lines of code, integrate multiple technologies, and require seamless connectivity. Meanwhile, product development cycles that once spanned years now demand delivery in months, driven by fierce competition and rapidly evolving customer expectations.

As development cycles get shorter while products must meet stricter regulations, sustainability requirements, and cybersecurity standards, engineers are defining the future of new product development by focusing on:

- Applying model-based product engineering (MBPE)

- Enabling intelligent, multidisciplinary product design

- Cultivating shared intelligence of products

- Leveraging AI-powered simulation-driven design

Applying model-based product engineering

While systems engineering focuses on managing complexity through requirements, architecture and integration across disciplines, model-based product engineering (MBPE) takes this further by replacing fragmented, document-centric engineering practices with a cohesive, model-centric approach. In this paradigm, digital models encompassing system architecture, behavior and requirements become the primary means of communication, analysis, and traceability throughout development.

These models serve as a single source of truth, automatically propagating changes across the system, enabling early verification and minimizing manual errors or conflicting specifications.

Enabling multidisciplinary, intelligent product design

As products incorporate more software, sensors, and AI, engineering teams need new approaches to cross-disciplinary development. These five capabilities are reshaping how teams design across domains.

Design exploration through Generative AI

Engineers can now explore creative design possibilities faster than ever through generative AI. Rather than manually creating and testing each design variant, AI automatically produces thousands of options that satisfy multi-domain constraints like structural strength, weight limits, material specifications, and manufacturing feasibility.

By combining powerful design generation with built-in simulation capabilities, Siemens’ AI tools quickly identify the best solutions from among countless possibilities. This gives engineering teams the power to innovate more efficiently and discover optimal designs that may have otherwise gone unexplored.

Integrated performance engineering

By embedding performance analysis directly within the design environment, engineers can monitor structural, thermal, and fluid behaviors as they work. Comprehensive performance engineering solutions from Siemens exemplifies this approach, allowing material choices and mechanical performance to be validated in real time, reducing design errors and accelerating refinement. This integration dramatically reduces dependency on external tools and accelerates time-to-market.

Concurrent design

Concurrent (or parallel) design aligns mechanical, electrical, and software engineering from day one, breaking siloed workflows and enabling early detection of integration issues. This approach cuts development time, lowers costs, and supports more cohesive systems—true to the principles of integrated product development. As a result, teams experience fewer late-stage surprises and more predictable outcomes.

Seamless electromechanical design

Engineering electromechanical products requires flawlessly linking mechanical and electrical systems—from mechanical structures to PCB layout and cable harness planning. Through a unified CAD and EDA environment, designers ensure that mechanical enclosures align with electronic components, harness complexity is managed, and E/E systems are seamlessly integrated. This unlocks faster iterations and minimizes costly mechanical-electronic clashes.

Robust electronical/electronic systems architecture

Modern products rely on complex electrical/electronic networks (e.g., sensors, control logic, power systems). Intelligent product design supports a model-centric architecture where requirements, signal integrity, harness routings, and software interactions are co-developed. These digital blueprints ensure traceability and rapid validation across physical and virtual domains—elevating quality and compliance.

Cultivating the product’s shared intelligence

Centralizing product data in a single, robust system is fundamental to competitive product innovation. When product data such as CAD files, BOMs, requirements, and test results are stored in one unified repository, teams can work with confidence knowing they have access to the latest information. Data centralization eliminates common challenges like version mismatches and duplicated work while streamlining communication across departments.

At the heart of the system lies a unified Bill of Materials (BOM) that consolidates all mechanical, electrical, and software components into a cohesive structure. Integration simplifies configuration management and version control while supporting the complexity of product variants and customization options. Teams across the organization, from engineering to procurement and quality assurance, can efficiently manage changes and assess their impact throughout the product lifecycle.

The result is a more agile development process where teams can collaborate effectively, maintain clear traceability, and make informed decisions based on consistent, up-to-date information. Managing data systematically reduces errors and miscommunication while accelerating product development cycles and maintaining high quality standards.

Gaining real product insights through AI-powered simulation-driven design

In today’s competitive environment, turning product insights into actionable strategies is essential for informed decision-making. These insights, derived from areas like virtual prototyping and predictive maintenance, enable teams to systematically align product features with what truly matters to users and the market.

However, effectively achieving this, particularly when leveraging AI-powered simulation-driven design, demands a dynamic and predictive understanding of a product’s entire lifecycle. Traditional approaches often fall short in providing the real-time, comprehensive view necessary for true optimization and foresight. This is precisely why digital twin technology has become fundamental for leading companies, offering the advanced capabilities needed to bridge the gap between digital design and real-world execution and drive unprecedented levels of insight.

The digital twin approach

A digital twin is a sophisticated virtual replica of a physical product, system, or process, continuously synchronized with real-world data from sensors, simulations, and operational systems. Unlike static models, digital twins evolve in real time, mirroring live behavior and enabling predictive insights throughout the product lifecycle.

This is where AI goes a step further, evolving the digital twin from a sophisticated replica into an intelligent, self-optimizing system. By integrating advanced AI and machine learning algorithms, digital twins can not only process and interpret the vast streams of real-time sensor and operational data but also learn from it. This enables them to identify complex patterns, predict future behaviors with unprecedented accuracy, and even autonomously suggest optimizations or generate new design iterations. In essence, AI supercharges the digital twin, allowing it to move beyond mirroring to anticipate, learn, and prescribe actionable insights.

By leveraging digital twin simulation in product development, teams can:

- Accelerate design iterations through early virtual prototyping, by testing structural integrity, thermal performance, fluid dynamics, and more before building any physical prototype.

- Optimize product performance continuously via thousands of “what-if” scenarios for maximum efficiency and resilience.

- Enable closed-loop feedback by feeding live field data back into the model for continual calibration, allowing AI and machine learning algorithms to continually calibrate and refine predictions, tightening alignment between virtual predictions and real-world outcomes.

- Predict maintenance needs by simulating wear, degradation, and failure modes, leading to smarter, proactive servicing and reduced downtime.

- Foster cross-disciplinary collaboration within organizations because engineering, manufacturing, and service teams work from a unified model, decisions become more coherent and traceable.

- Mitigate risk efficiently by simulating extreme conditions, rare events, and hazardous scenarios virtually, allowing safe, scalable testing without physical or regulatory constraints.

In essence, digital twins bridge the gap between digital design and real-world execution. They transform the development process into an intelligent, adaptive system, enhancing speed, quality, innovation, and lifecycle value, helping companies across a vast number of industries to deliver high-performing, compliant products faster, with greater innovation.

Business impacts: Innovation, collaboration, speed, and sustainability

Effective product development processes are the basis of business growth and innovation. By structuring workflows across ideation, design, testing, and launch, companies can realize four key competitive advantages:

- Boosting collaboration between teams: When engineering, marketing, compliance, and sustainability teams collaborate cohesively, innovation flourishes. Integrating cross-functional disciplines, often via collaborative platforms and co-design, breaks down silos, enabling faster decision-making and higher-quality outcomes.

- Shortening product design cycles: Accelerated product design cycles directly impact speed-to-market. Through techniques like digital prototyping and virtual testing, iterations occur more swiftly, and bottlenecks are eliminated. As a result, companies gain cost savings, increased adaptability, and the ability to respond more quickly to market demands.

- Enabling efficient and integrated development: Efficiency in product development means optimized resource use and minimized waste. Adaptive processes, driven by real-time data, agile workflows, and strategic PLM, allow teams to continually align priorities with business goals, maximizing productivity while preserving product quality.

- Reaching sustainability goals: Incorporating sustainable engineering processes from the very beginning shapes design choices and mitigates environmental risk. Life-cycle assessments, sustainable design strategies, and material optimization reduce emissions, waste, and lifecycle cost, further unlocking innovation and maximizing business impact.

Product development solutions for industries

Every industry presents unique challenges—from rapid innovation in consumer electronics to stringent safety standards for medical devices. Effective product development solutions empower businesses to meet these demands by offering domain-specific tools, collaborative workflows, and simulation-driven strategies. As an industry leader in product development, Siemens’ solutions deliver end-to-end capabilities that drive performance, compliance, and innovation.

Key industries benefiting from these solutions include:

- Aerospace & Defense

- Automotive

- Battery

- Consumer Products & Retail

- Consumer Goods

- Electronics

- Energy & Utilities

- Heavy Equipment

- Industrial Machinery

- Marine

- Medical Device

This spectrum of industry-specific solutions showcases how well-integrated product development solutions enable companies to innovate faster, stay compliant, and deliver sustainable, high-performance products tailored to their sector’s exacting standards.

Final thoughts

Modern product development is a strategic, accelerated, and intelligent process. By embracing product design engineering best practices and integrating AI, digital twins, and Siemens solutions into the product lifecycle, businesses can dramatically shorten cycles, reduce risk, improve sustainability, and enhance innovation.

To learn more about Siemens’ holistic approach to product engineering and available integrated solutions, visit our Accelerated Product Development digital thread today.

FAQs

Q: What is product design engineering?

A: Product design engineering is the backbone of turning conceptual innovation into real-world products, combining design ingenuity, engineering precision, and market insight to shape the products we rely on every day.

Q: How does the product development process support sustainability?

A: The product development process supports sustainability by embedding eco-friendly strategies and technologies across the entire lifecycle—from initial concept to disposal. Integrated, sustainability-led product development drives innovation, cost efficiency, and long-term competitiveness. By designing with environmental impact in mind companies not only reduce their ecological footprint but also create products that resonate with eco-conscious markets, unlock new business models, and support a more sustainable future.

Q: What is multidisciplinary design?

A: Multidisciplinary design is an approach in product development where experts from diverse fields including mechanical, electrical, software, materials, human factors, and business, collaborate seamlessly throughout the design process. Rather than working in isolation, these specialists converge early to holistically address complex challenges, ensuring design decisions reflect a balance of technical feasibility, user experience, regulatory compliance, and market viability.

Q: How does rapid prototyping improve product optimization?

A: Rapid prototyping significantly boosts product optimization by turning design ideas into tangible prototypes fast, allowing for rapid iteration, discovery, and refinement. Other examples include:

- Discovers design flaws early

- Enables rapid iteration

- Tests real-world material behavior

- Accelerates validation cycles

- Improves stakeholder communication

- Promotes innovation through experimentation