AI in product development: How to harness intelligent product design

Today’s product developers face a perfect storm of competing demands: shrinking development cycles, escalating product complexity, and relentless pressure to deliver more with less. Traditional design approaches, built on sequential processes and incremental improvements, are faltering under these demands.

Artificial intelligence (AI) brings something far more valuable than just faster execution of old methods. It represents a fundamental rethinking of the product development process itself. By flipping conventional approaches on their head and exploring possibilities beyond what human designers could reasonably consider, AI is changing not just how quickly we design products, but what we can create.

In this article, we’ll examine how AI is transforming product development, exploring the specific technologies changing design practices today to the evolving partnership between creative humans and intelligent tools.

Core capabilities of AI in product development

No single AI technology is transforming product development. Instead, several complementary capabilities are working together to address different challenges in the product design process. From concept creation to performance validation to design refinement, these technologies tackle the limitations that have constrained innovation for decades.

Four core AI technologies are driving this transformation. Let’s examine each one and how they are changing fundamental aspects of product development.

Generative AI for product design

Generative design has evolved significantly since its roots in 1980s topology optimization. What’s transformative today isn’t the concept itself, but how modern computing power, advanced algorithms, and AI techniques have made it practical for everyday engineering challenges.

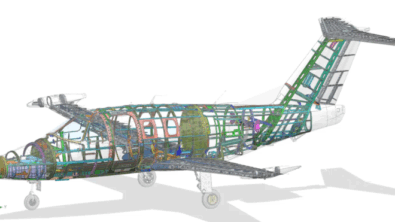

The approach fundamentally inverts the traditional design workflow. Instead of starting with a concept and refining it, engineers define performance requirements, constraints, and boundary conditions. The algorithm then explores thousands of possibilities to identify optimal solutions, revealing alternatives that would be impractical to discover through traditional methods.

The technology combines topology optimization with machine learning to produce solutions that challenge conventional thinking. These designs frequently feature organic, nature-inspired forms: structural components with intricate internal lattices, heat sinks with irregular patterns maximizing surface area, or fluid channels with unexpected geometries improving flow characteristics.

Generative AI proves most valuable when:

- Projects require balancing multiple competing performance criteria

- Product designs must achieve maximum performance within tight constraints

- Teams need to rapidly evaluate diverse alternatives early in product development

- Manufacturing methods (particularly additive) can produce complex geometries

Despite its power, limitations remain. Using generative AI for product design requires thorough validation, as their unexpected forms may introduce unfamiliar behavior. Many remain challenging to produce with traditional manufacturing methods and typically need refinement to address aesthetic considerations and assembly requirements.

Nevertheless, generative AI is transforming the process from manually creating geometry to defining problems and exploring computer-generated solutions. What’s made this transition practical is the convergence of greater computing power, advanced algorithms, and manufacturing innovations, bringing powerful optimization capabilities into mainstream product development.

Importantly, generative design often works hand-in-hand with AI in 3D modeling. While generative AI explores design spaces and proposes optimized solutions, AI-driven 3D modeling brings these concepts into tangible digital form. Together, they accelerate prototyping, enable rapid visualization of complex geometries, and bridge the gap between computationally generated ideas and practical product design. This natural progression makes AI in 3D modeling the next critical step in transforming how teams move from concept to prototype.

AI in 3D modeling

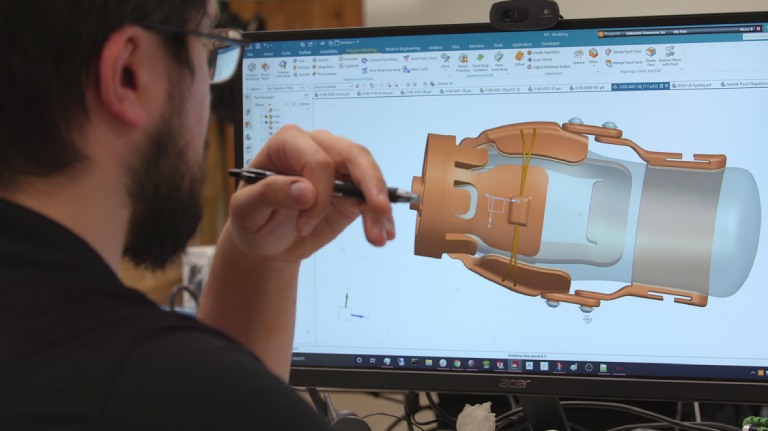

AI in 3D modeling builds on the possibilities of generative design by converting algorithm-driven concepts into detailed, manufacturable models. These intelligent tools accelerate the transition from idea to prototype while ensuring that designs remain practical, optimized, and aligned with performance goals.

Key capabilities include:

- Automated geometry creation – quickly generating 3D forms based on design intent and constraints.

- Mesh optimization – refining structures to minimize material use while preserving strength and durability.

- Manufacturing adaptability – preparing models for different processes, from additive to subtractive methods.

- Rapid visualization – enabling interactive digital prototypes to communicate ideas clearly across teams.

- Immersive review – supporting early validation of ergonomics, aesthetics, and usability.

For product designers, these capabilities unlock faster prototyping cycles and better collaboration across engineering, marketing, and customer teams. Early visualization and feedback reduce the risk of costly redesigns later in the process and help align stakeholders around a shared product vision.

The next step after creating detailed 3D models is ensuring they will perform as expected in real-world scenarios. This naturally leads into AI-powered simulation and performance engineering, where digital prototypes are tested and validated to confirm reliability, safety, and efficiency.

AI-powered simulation & performance engineering

AI has been part of simulation technology for years, with statistical methods and simplified physics models long used to accelerate certain analyses. What’s changing now is the scale, sophistication, and accessibility of these approaches. Specialized techniques have evolved into mainstream capabilities that fundamentally alter engineering workflows.

Today’s AI-powered simulation builds on this foundation through advanced machine learning-based surrogate models. The approach remains pragmatic: engineers run a strategic set of full-fidelity simulations across the parameter space of interest. Machine learning algorithms then create a surrogate that can predict performance for new product designs with remarkable accuracy.

For validation engineers and design teams, the acceleration is dramatic. Simulations that once consumed hours return results in seconds while maintaining accuracy within the trained parameter space. This compression of the feedback loop changes how engineering decisions are made:

- Design engineers can evaluate hundreds of alternatives in the time previously needed for a few

- Systems engineers receive immediate performance feedback while exploring integration options

- Controls engineers can quickly validate behavior across a wider range of operating conditions

- Electrical engineers can assess thermal management across numerous configuration scenarios

Leveraging performance engineering solutions from Siemens, teams can confidently integrate AI-driven simulations into their workflows, ensuring that product concepts are validated early and refined efficiently throughout the development cycle. This strengthens both speed and reliability in delivering high-performance designs.

While simulation has long been integral throughout product development, AI is transforming its role. Instead of being a periodic analysis that requires specialized expertise and dedicated computing resources, simulation is becoming an interactive design companion—providing near-instantaneous feedback during the creative process itself.

The primary constraint remains that surrogate models can only make reliable predictions within the parameter space they’ve been trained on. Venturing into completely new design territory still requires traditional simulation. For this reason, AI doesn’t replace conventional approaches but enhances them, with traditional methods remaining essential for final validation and novel designs.

techniques are helping transform product development from a sequential process into a fluid exploration—where performance implications are understood almost immediately as design decisions are made. This naturally leads to the next layer of innovation: AI-embedded CAD tools, which bring intelligent support directly into the daily design environment.

AI-embedded CAD tools

The most pervasive AI in product development operates invisibly within everyday design environments. These capabilities range from straightforward pattern recognition to sophisticated machine learning systems that adapt to individual work patterns and team practices.

Unlike generative design or simulation acceleration that engineers consciously engage with, these embedded tools work behind the scenes, augmenting the interface between designer and software. For professionals who spend hours daily in complex software environments, these capabilities transform the user experience through:

- Contextual command prediction that suggests tools based on the current task

- Automated feature recognition that identifies and processes common geometry

- Design pattern recommendations drawn from similar components or organizational standards

- Workflow optimization that adapts interfaces based on specific engineering discipline

Software architects and developers have focused on making these capabilities practical and unobtrusive rather than technically impressive. The result is a subtle but significant shift in how engineers interact with their tools.

The benefits manifest differently across disciplines but share a common theme: reducing friction between creative intent and technical execution. Automated feature recognition speeds modeling of common elements. Intelligent component placement improves layout efficiency. Adaptive interfaces streamline complex integration tasks. Code suggestions accelerate development while maintaining project standards. Each capability removes small barriers that traditionally interrupt creative flow.

The impact extends beyond individual productivity. As these systems observe more designers across more projects, they capture organizational knowledge and best practices. Solutions developed by experienced team members become accessible to others through AI-powered suggestions, creating institutional memory embedded within the design environment itself.

While vendors typically highlight productivity metrics, the deeper transformation is qualitative. By handling repetitive operations and reducing cognitive load, these tools allow designers to maintain creative flow and focus on problem-solving rather than software operation. The technology becomes increasingly transparent, allowing engineers to concentrate on the design challenge rather than the mechanics of the design environment.

AI across the product lifecycle

Artificial intelligence is no longer limited to isolated tasks like design automation or data analysis; it now spans the entire product development lifecycle. From early concept generation to market launch, AI acts as a unifying thread that connects creativity, engineering, and decision-making.

By weaving AI into every phase of product development, organizations gain the ability to innovate faster, reduce risk, and deliver higher-performing products. This holistic approach accelerates product development from a series of linear steps into a continuous, intelligent process that adapts and improves with every iteration.

AI for product management

Beyond design tasks, AI supports product managers by analyzing market trends, customer feedback, and lifecycle data. This data-driven intelligence allows for more confident prioritization of features, cost-benefit tradeoffs, and roadmap planning.

When combined with product design and PLM solutions, AI insights help connect strategy with execution.

AI in PLM: Enabling collaboration and data-driven workflows

Product Lifecycle Management (PLM) systems infused with AI transform how teams manage complexity. Intelligent PLM capabilities can automatically classify design data, detect inconsistencies, and recommend reuse of proven components. They also support predictive insights into supply chain risks, sustainability factors, and regulatory compliance.

By embedding AI into PLM solutions, organizations break down silos between design, engineering, and manufacturing. The result is faster product development cycles, fewer errors, and a stronger foundation for innovation.

Integration challenges and implementation strategies

Adopting AI technologies individually can bring meaningful improvements, but their greatest potential is realized when they work together as part of an integrated ecosystem. Organizations achieving the strongest results approach this systematically, focusing on workflows and collaboration rather than piecemeal adoption.

The most significant challenges are not technical but organizational. As AI tools bridge boundaries between mechanical design, electrical engineering, software development, and manufacturing, cross-domain collaboration becomes essential. Data practices must also evolve to handle the volume, variety, and accessibility needs of AI-driven development.

Key challenges include:

- Cross-domain collaboration – ensuring design, engineering, and manufacturing teams share a common workflow.

- Data management – building practices that support large-scale information handling and accessibility.

- Team structures – rethinking traditional silos to enable optimization across multiple specialties.

Organizations that succeed often start with targeted use cases. Rather than deploying AI broadly, they focus first on specific bottlenecks or high-impact applications. This incremental approach delivers measurable results while giving teams the time to develop new skills and confidence.

Strategies for success typically include:

- Incremental adoption – piloting AI in areas where quick wins are achievable.

- Centers of excellence – combining technical expertise with change management to support wider adoption.

- Skill evolution – training engineers to understand AI’s capabilities and limitations, enabling them to frame problems effectively.

Perhaps most critical is addressing the conceptual shift in engineering practice. Engineers don’t need to become AI specialists, but they do need to transition from directly creating solutions to defining solution spaces and evaluating AI-generated alternatives. This mindset shift enables teams to leverage AI as a collaborator rather than just a tool.

Human-AI partnership in engineering

As these technologies mature, the relationship between engineers and AI systems is evolving from tools that execute commands to collaborators that contribute to the solution process. This shift is subtle but profound, with implications across engineering disciplines.

Knowledge capture and distribution represent one of the most valuable aspects of this partnership. AI systems observe solutions across projects and organizations, identifying patterns and transferring insights that might otherwise remain isolated. Engineering knowledge that traditionally took years to develop through experience becomes accessible to teams regardless of location or seniority.

Rather than replacing engineering expertise, these technologies redefine it. The value of experience shifts from memorization of solutions to problem framing and solution evaluation. Engineers spend less time on repetitive tasks and more time on critical decisions that require judgment, creativity, and contextual understanding that AI cannot provide.

Concerns about skill obsolescence are natural but largely misplaced. History shows that automation typically enhances rather than replaces professions. The most successful engineers will be those who understand both their domain and how to leverage AI capabilities within it, combining technical depth with the ability to work across traditional boundaries.

Future outlook

The capabilities discussed represent early stages in what will likely be a decades-long transformation of product development. The clear trajectory is toward increasingly seamless integration of these technologies, with boundaries between them becoming less distinct over time.

Emerging capabilities on the horizon include advanced natural language interfaces that allow engineers to specify requirements conversationally, improved reasoning about physical constraints and manufacturability, and systems that better understand design intent rather than just geometric representation.

Engineering education and professional development will necessarily evolve in response. Universities are already incorporating AI tools into engineering curricula, focusing less on routine calculations and more on problem definition, constraint specification, and critical evaluation of machine-generated solutions.

The competitive landscape will increasingly favor organizations that successfully integrate these capabilities into their development processes. The advantage will come not from having the technology, which will become widely available, but from developing the organizational structures, workflows, and culture that leverage it most effectively.

Beyond tools: Engineering’s AI-augmented future

AI in product development is fundamentally changing how products are conceived, designed, validated, and manufactured. The technologies we’ve examined, generative design, AI-powered simulation, and embedded design tools, represent complementary capabilities that together transform product development from a linear, constrained process into something more dynamic, exploratory, and powerful.

For engineering leaders navigating this transformation, the focus should be on integrating these technologies into cohesive workflows rather than implementing them as isolated point solutions. The greatest challenges will be organizational rather than technical: developing new processes, evolving team structures, and cultivating skills that leverage the full potential of AI in product development.

The goal isn’t artificial intelligence replacing human engineers, but rather augmented intelligence. Humans and machines collaborate in ways that amplify the strengths of each. In this partnership, machines handle computation-intensive exploration and routine tasks, while humans provide creativity, judgment, and contextual understanding. Together, they expand what’s possible in ways neither could achieve alone.

Final thoughts

AI is not a single tool; it is a catalyst for rethinking the entire product development process. From generative design to 3D modeling, from CAD automation to AI-powered PLM, intelligent technologies accelerate innovation while ensuring quality and performance.

Organizations that successfully integrate these capabilities with performance engineering, simulation, and product design solutions position themselves to lead in an increasingly competitive marketplace. The future belongs to teams that embrace AI as a collaborative partner in every stage of product development.

Frequently asked questions about AI in product development

How is AI different from traditional product development tools?

AI in product development doesn’t just speed up existing processes—it creates new possibilities. Traditional tools rely on manual input and sequential workflows, while AI explores vast solution spaces, learns from prior designs, and predicts performance in real time. This shift enables engineers to move beyond problem-solving alone into problem-framing, where AI helps generate and evaluate alternatives that humans may never have considered. By expanding creative exploration and accelerating validation, AI in product development empowers teams to design smarter, more innovative, and better-performing products.

Where can engineers get the most value out of using AI in product development?

AI in product development drives innovation by generating new ideas, optimizing designs, and testing them virtually—helping companies create smarter, more efficient, and customized products faster.

AI in product development enhances innovation through design exploration, simulation, and lifecycle management. Generative AI expands design options by producing countless variations based on specific requirements, while AI-powered simulation accelerates validation by testing performance virtually before physical prototyping. AI-driven 3D modeling speeds up prototyping with accurate digital twins, and AI in PLM (Product Lifecycle Management) ensures consistency, traceability, and collaboration across teams. Together, these technologies reduce cycle times, cut costs, promote sustainability, and lead to better-performing products that align more closely with customer needs.

What impact does AI have on sustainable product design?

AI helps teams design more sustainable products by optimizing materials, reducing waste, and improving energy efficiency throughout the product lifecycle.

AI integrates sustainability directly into the design process rather than treating it as an afterthought. Algorithms can recommend lighter or more eco-friendly materials, identify geometries that minimize resource use, and run simulations to predict energy efficiency before production begins. AI-powered PLM systems also support lifecycle assessments, helping organizations evaluate the environmental impact of sourcing, manufacturing, use, and disposal. This allows engineers and product managers to balance performance, cost, and sustainability goals simultaneously, enabling smarter, greener product development.

How can AI for product design be used to innovate products?

AI for product design drives innovation by generating new ideas, optimizing designs, and testing them virtually—helping companies create smarter, more efficient, and customized products faster.

AI enhances product innovation by combining creativity with data-driven optimization. Through generative AI, designers can explore countless variations of a product based on functional requirements, materials, or user preferences, uncovering solutions that human designers might not consider. This allows for breakthroughs in aesthetics, ergonomics, and customization. Meanwhile, AI-powered simulation tests these designs in virtual environments—modeling stress, durability, and performance—so teams can refine concepts before committing to physical prototypes. Together, these tools enable rapid iteration, reduce costs and risks, and promote sustainable use of resources. The result is a product development process that is not only faster and more efficient but also capable of producing innovative, market-ready products that better meet customer needs.

What challenges should companies expect when adopting AI in product development?

Integration and skill adaptation.

Technical tools are advancing rapidly, but the bigger hurdle is organizational readiness. Teams must adapt workflows, embrace cross-domain collaboration, and develop the ability to define problems for AI systems. Success comes from combining technology adoption with cultural and skills evolution.

How is machine learning used throughout the product design process?

Machine learning (ML) supports product design by analyzing data, predicting performance, and generating design alternatives, helping teams make faster, more informed decisions at every stage of development.

Machine learning enhances product design by learning from past projects, simulations, and performance data. In early stages, ML models can generate concepts, recognize patterns in customer needs, and suggest proven design approaches. During design refinement, ML-powered tools optimize geometry, predict performance outcomes, and adapt designs for different manufacturing methods.

In later stages, machine learning supports simulation acceleration, enabling engineers to test hundreds of design variations quickly. It also integrates into PLM systems to detect inconsistencies, recommend component reuse, and provide insights across the product lifecycle. By weaving ML into the entire process, teams gain a continuous feedback loop that accelerates innovation while reducing risk.