Modern product optimization: How the best products never stop evolving

Every industry-leading product has one thing in common: it didn’t stop at “good enough.”

The electric vehicles that travel farther on a single charge. Wind turbines that generate more power with less maintenance. Smartphones and laptops that pack more capability into thinner designs each year. None of these feats happened by accident—they’re the result of the relentless pursuit of product optimization.

Everyday engineers and designers are juggling more than ever. Better performance? Check. Lower costs. Absolutely. Sustainability targets? Non-negotiable. Oh, and it all better be done faster than the competition. Traditional development methods like endless physical prototyping, siloed teams, and manual testing simply can’t keep up with these modern expectations.

So, what’s changed?

Companies across every sector are embracing digital transformation. They’re using AI to predict problems before they occur, running thousands of simulations instead of building dozens of prototypes, and creating digital twins that test, learn, and optimize in real-time.

Siemens is at the center of this shift, providing an integrated environment where teams can continuously refine products throughout their entire lifecycle, from initial concept through production and into operation.

Because in today’s market, optimization isn’t a final step. It’s the entire journey.

What is product optimization?

At its core, product optimization is about asking one critical question: How do we make this product better without making it more expensive, slower to market, or harder on the planet?

It’s the art and science of refining a product’s design, materials, and performance to find the best possible balance between cost, quality, efficiency, and sustainability. Sometimes it means just shaving grams off a component. Other times it’s redesigning an entire assembly to use 30% less energy. The goal remains the same: maximize impact, minimize waste.

How optimization fits into the product development process

Optimization doesn’t wait until you’ve built something to tell you it’s wrong. It kicks in once you have a preliminary design. That’s when engineers start stress-testing designs against real-world conditions. How does it handle weight? What about durability under extreme temperatures? Will it actually survive manufacturing at scale?

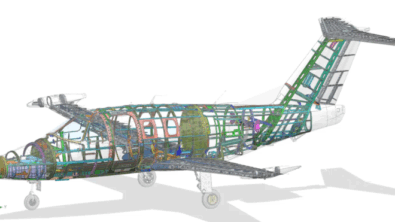

Using advanced simulation solutions, teams can spot weaknesses and explore alternatives without building a single physical prototype. It’s an iterative dance: test, refine, test again, until the product hits its targets for performance, manufacturability, and compliance.

In Siemens’ integrated digital ecosystem, product optimization isn’t confined to one stage or one team. It’s woven throughout the entire product lifecycle—from initial concept through engineering and production, all the way to post-launch feedback loops. The result? Products that get smarter at every stage, not just at the end.

Traditional vs. modern product optimization

The old way: Traditional product optimization relied heavily on manual processes, physical testing, and departmental silos. Engineers worked sequentially, designing a part, building a prototype, testing it, and then reworking the design based on results. This approach was time-consuming, expensive, and limited by how many physical iterations could realistically be tested. Optimization often focused on individual components rather than entire systems, with decisions guided largely by experience and intuition.

The new reality: Modern product optimization is fast, data-driven, and connected. Engineers now use simulation, AI, and cloud computing to explore thousands of design variations virtually, eliminating the need for excessive physical prototyping. The process is collaborative rather than isolated, allowing mechanical, electrical, and software teams to work within a shared digital environment where every change automatically updates across disciplines.

Digital twins and the digital thread enable continuous feedback loops, where real-world performance data informs ongoing refinement. This isn’t just an incremental improvement, but rather a fundamental shift in how products are developed.

5 stages of the product optimization process

The product optimization process traditionally follows five interconnected phases:

- Data Collection & Requirements Definition – Gather customer expectations, regulatory requirements, and performance goals.

- Modeling & Simulation – Create digital prototypes that replicate real-world physics.

- Analysis & Evaluation – Identify inefficiencies or design weaknesses.

- Iteration & Refinement – Apply design modifications and re-test virtually.

- Validation & Implementation – Confirm optimized results through physical or digital validation.

These stages aren’t linear checkboxes. They’re a continuous cycle where teams move fluidly between phases, with insights from one stage immediately informing the other.

Although the product optimization process provides the foundation for improving performance, the process has changed dramatically over time, revealing how companies adopting digital transformation are setting new standards for innovation while they face increasingly complex challenges.

Challenges in the product optimization process

As products become smarter, lighter, and more connected, the product optimization process grows exponentially more complex. As we explored earlier, engineers are no longer refining a single component in isolation but rather collaborating with mechanical, electrical, and software disciplines.

Every design decision today ripples across multiple disciplines. Change a material, and it affects thermal performance. Adjust a geometry, and it impacts manufacturability. Add an embedded sensor, and it changes the power budget. The result is a constant tug-of-war between innovation and constraint—one that can slow even the most advanced teams if not managed intelligently.

Despite technological advancements, engineers still face several challenges:

- Conflicting design goals: improving one characteristic can degrade another.

- Data fragmentation: disconnected systems hinder collaboration.

- Simulation bottlenecks: large models can require significant computing resources.

- Late feedback: physical testing occurs too far downstream.

- Sustainability pressures: regulations demand eco-friendly designs and materials.

Siemens addresses these obstacles through a connected digital ecosystem. Unified data platforms eliminate silos, while scalable cloud computing accelerates simulation. AI-driven optimization algorithms help balance conflicting objectives.

Most importantly, a digital thread connects every stage of product development, ensuring insights from one domain instantly informs another. When a mechanical engineer adjusts a component’s geometry, the thermal and electrical teams see the impact in real-time. When manufacturing flags a production issue, it feeds back into design before the next iteration begins.

Product design optimization: Designing for performance and efficiency

Product design optimization focuses on improving form, function, and manufacturability through simulation-driven design. Engineers use topology optimization, generative design, and parametric modeling to explore creative yet practical design options.

For example, a design team might use Siemens NX and Simcenter to reduce an aircraft bracket’s weight by 20% while maintaining structural integrity. Generative algorithms automatically adjust geometry based on performance criteria, producing shapes that would be impossible to discover manually.

Once optimal design solutions are identified, tools like DesignCenter help engineering teams standardize and reuse proven design elements across projects. By managing libraries of optimized components, materials, and design standards, DesignCenter ensures that hard-won optimization insights don’t get lost between projects. This creates a feedback loop where each optimization effort builds organizational knowledge, accelerating future development cycles.

This approach not only enhances performance but also reduces material waste and energy consumption, aligning with sustainability goals. It embodies the core principle of modern engineering: optimize early, iterate often, and capture what works.

Understanding product characteristics

But what exactly are engineers optimizing? At the center of every optimization effort are product characteristics, the measurable and qualitative properties that define how a product behaves, looks, and performs. These include:

- Mechanical characteristics: strength, stiffness, weight, and material selection.

- Thermal and electrical characteristics: conductivity, efficiency, and power usage.

- Aesthetic characteristics: color, ergonomics, shape, and user interface.

- Sustainability characteristics: recyclability, emissions footprint, resource usage.

Digital modeling allows engineers to analyze these characteristics in virtual form, exploring trade-offs early. For instance, reducing a component’s weight might improve efficiency but compromise durability. By virtually simulating these trade-offs, engineers can make informed decisions faster and with greater confidence.

Beyond the design phase: iterative optimization and continuous improvement in action

Optimization doesn’t stop when a product ships. With IoT-connected products feeding real-world performance data back to engineering teams, optimization becomes a living process.

That aircraft bracket we mentioned? Once it’s in service, sensors can track stress patterns, temperature fluctuations, and wear over time. This data flows back into the digital twin, informing the next generation of design improvements.

This process is continuous product optimization—where products don’t just launch, they evolve. Design flaws get predicted and corrected before they become field failures. Resources get used more efficiently with each iteration. Product lifecycles extend because designs adapt to actual customer needs, not just predicted ones.

The result? Faster innovation cycles, higher reliability, and products that get smarter over time.

The continuous advantage

Product optimization has evolved from a sequential engineering step to an intelligent, ongoing process that drives innovation at every stage. For both new and existing products, it ensures designs are smarter, leaner, and more sustainable—not just once, but over the product’s entire lifecycle.

With Siemens, organizations gain more than tools; they gain a holistic framework for continuous product optimization that connects every stage of development. The future of innovation belongs to those who optimize relentlessly, and Siemens is the partner leading that transformation.

Real-life FAQs about product optimization from product designers and engineers

How is product optimization actually done in real engineering workflows?

Product optimization is done by defining requirements, building a baseline design, running simulations to evaluate performance, and iterating until the best balance of cost, performance, manufacturability, and reliability is achieved.

In real-world engineering, optimization is not a single step but an ongoing cycle woven into the entire product development process. Engineers begin by establishing clear design requirements such as structural strength, thermal thresholds, weight targets, manufacturing constraints, and cost limits. After creating a baseline CAD model, they use simulation tools to evaluate how the product behaves under real-world conditions. The insights from these simulations guide adjustments to the geometry, materials, and configuration. Modern digital workflows make this process much more efficient by integrating simulation, digital twins, and AI-assisted exploration. Instead of relying solely on trial and error, engineers can now evaluate thousands of variations virtually, identify the most promising options, and validate those designs before a physical prototype is ever built. Optimization ultimately becomes the combination of engineering judgment, simulation data, and continuous refinement.

What should designers optimize for, and how do you know when a design is “optimized enough”?

Designers usually optimize for performance, cost, manufacturability, durability, weight, or sustainability. A design is considered “optimized enough” when further improvements would require more time, money, or risk than they are worth.

Optimization is all about striking the right balance between competing objectives rather than pursuing perfection. The challenge is that improving one area often affects another. The point at which a design is “optimized enough” usually becomes clear when the effort required for additional improvements outweighs the benefit they would deliver.

Modern simulation tools and digital threads help quantify this balance by showing how design changes impact multiple criteria at once. This allows teams to make decisions based on meaningful data rather than guesswork. Ultimately, a design is considered sufficiently optimized when it meets requirements, fits within budget, and is ready for manufacturing without exposing the project to diminishing returns.

How do engineers balance multi-domain trade-offs, like cost vs performance or strength vs manufacturability?

Engineers balance trade-offs by using simulation, domain knowledge, and cross-functional collaboration to understand how changes affect performance, cost, and manufacturability, ultimately choosing the solution that meets the project’s overall goals.

Managing trade-offs is one of the most challenging aspects of product optimization. Improving one aspect of a design often creates new challenges elsewhere—a lighter design might cost more to produce, a more durable design might require additional components, and a thermally efficient design might introduce geometric complexity that slows manufacturing. Engineers evaluate these trade-offs by combining simulation insights with practical knowledge of materials, processes, and production methods. Multi-domain simulation makes it easier to see how a change in one area affects performance in another. Cross-functional collaboration is also essential, as mechanical, electrical, and manufacturing teams each contribute a different perspective. Digital transformation has improved this process significantly by enabling real-time data sharing and integrated design environments, allowing teams to evaluate trade-offs using shared information rather than disconnected viewpoints. The goal is always to find a balanced design that satisfies engineering requirements while remaining feasible and cost-effective.

When is the right time to optimize—during concept development or later in detailed design?

Optimization works best when introduced early at a high level, then refined later with detailed data. Early exploration prevents dead-end concepts, while late-stage optimization ensures final designs are ready for production.

Applying optimization at the right stage is critical for avoiding wasted work and costly redesigns. Teams that optimize too early risk investing time in refining a design that will ultimately change once requirements or constraints evolve. But waiting too long to optimize can result in late discovery of performance or manufacturing issues, forcing major rework. The most effective approach is a two-phase method.

During the concept stage, engineers use high-level models and quick simulations to understand the feasibility of different design directions. This helps eliminate weak concepts early and prevents expensive mistakes later. As the design matures, detailed optimization focuses on geometry refinement, material selection, manufacturability improvements, and cost reduction. Modern simulation workflows allow both phases to be completed faster and with greater confidence. Optimization becomes a fluid and iterative practice that evolves alongside the product.

What tools or skills do engineers need to perform effective product design optimization?

Engineers need strong fundamentals in CAD, simulation, materials, and manufacturability, along with growing familiarity with AI-assisted design, generative tools, and integrated digital workflows.

Effective product design optimization requires a combination of technical knowledge, software proficiency, and system-level thinking. Engineers must understand how to create robust CAD models, run accurate simulations for structural, thermal, or fluid performance, and interpret the results in a meaningful way. Material science plays a role in selecting the right combination of strength, weight, and cost, while manufacturability knowledge helps ensure designs can be produced efficiently.

Increasingly, engineers are also using AI-driven tools that automate design exploration, identify performance trends, or evaluate thousands of variations in minutes. Familiarity with digital twin technology, digital threads, and integrated PLM workflows gives engineers an advantage in managing data continuity across the design process. Programming or scripting skills can also be useful for customizing optimization routines. Ultimately, the most valuable skill is the ability to integrate these tools and insights into a cohesive, iterative approach that improves product performance while meeting practical production requirements.

What is product design optimization, and why is it important for modern engineering teams?

Product design optimization is the practice of refining a design to achieve the best balance of performance, cost, durability, and manufacturability. It’s important because it helps teams build better products faster while reducing risk and minimizing unnecessary development costs.

Product design optimization plays a critical role in modern engineering because products are more complex than ever before. Teams need a reliable way to evaluate trade-offs, test different ideas, and make data-driven decisions without relying solely on slow physical prototypes. Product design optimization allows engineers to explore many variations of a design, understand their performance through simulation, and select the best option before moving forward. This reduces development costs, shortens time-to-market, and improves overall product quality. It also helps teams address cross-functional challenges, such as balancing mechanical performance with electrical layout, achieving weight targets without compromising durability, or ensuring manufacturability while controlling cost. As digital tools like simulation, generative design, and AI continue to evolve, product design optimization is becoming an essential competency for organizations aiming to stay competitive and innovate more efficiently.