Product BOM management: How integrated BOMs transform modern product development

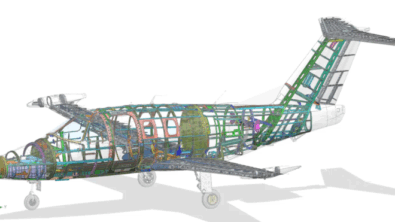

The rising complexity of today’s products, which now seamlessly blend mechanical components, electronics, embedded software, and connected features, underscores an unprecedented need for accuracy, collaboration, and cross-functional visibility. At the center of this complexity lies one of the most foundational assets in product development: the product BOM.

A product BOM (Bill of Materials) is far more than a list of parts. It is the structural backbone of the entire product lifecycle, defining what is built, how it’s built, and how it evolves over time. But in today’s era of high-speed innovation, global teams, and sustainability demands, simply having a BOM isn’t enough. Organizations need product BOM management that is connected, integrated, and digitally driven.

This blog explores what a product BOM is, how it fits into modern product development, why traditional BOM practices fall short, and how digital transformation enables integrated BOM management across mechanical, electrical, electronic, and software domains.

What is a product BOM?

A product BOM is a structured, hierarchical representation of every item required to build, assemble, test, ship, and service a product. It includes:

- Raw materials

- Mechanical components

- Electronics

- Embedded software

- Fasteners

- Sub-assemblies

- Manufacturing instructions

- Documentation

- Specifications and compliance data

In other words, the product BOM defines the product in its entirety.

Key types of product BOMs

While the product BOM serves as the comprehensive blueprint, different teams require specific perspectives tailored to their unique functions. This leads to the emergence of specialized BOMs:

- Engineering BOM (EBOM): This is the design-centric view organized by the product’s functional and design structure. It details the components, sub-assemblies, and relationships as conceived by engineers, often focusing on intellectual property and design intent.

- Manufacturing BOM (MBOM): Derived from the EBOM, the MBOM reconfigures the product structure to reflect how it will actually be built. It includes manufacturing processes, phantom assemblies, packaging, and possibly consumables, optimizing for production efficiency and cost.

- Service BOM (SBOM): This version is optimized for maintenance, repair, and overhaul (MRO) activities. It identifies replaceable units, service kits, and diagnostic parts, helping service technicians efficiently support the product throughout its operational life.

Understanding these distinct perspectives is crucial, as each BOM type is essential for its respective domain. The challenge, and the opportunity, lies in ensuring they remain harmonized rather than becoming isolated silos.

A well-managed product BOM becomes the central source of truth for all downstream activities. Engineers rely on it for design accuracy, manufacturing teams depend on it for build instructions, quality teams track compliance through it, and service departments use it to support customer repairability. That’s why errors, inconsistencies, and version conflicts within a BOM can ripple across the entire lifecycle with costly consequences.

And that brings us to the real distinction: creating a BOM is one thing. Managing it effectively is something entirely different—and far more complex.

How product BOM management fits into the product development process

To appreciate the value of product BOM management, it helps to understand its role in the full product lifecycle. From the moment a concept takes shape, the BOM becomes the product’s digital DNA, evolving alongside each phase:

- Concept and ideation – Early BOM structures help teams estimate costs, evaluate potential materials, and assess feasibility.

- Detailed design – Engineers define components, configure assemblies, and refine the BOM as the product matures.

- Simulation and validation – The BOM ensures simulations are performed on accurate configurations and variants.

- Manufacturing planning – MBOMs align production steps with design intent.

- Supply chain coordination – Sourcing, procurement, and vendor collaboration all depend on up-to-date BOM data.

- Production and assembly – The product BOM drives work instructions, process planning, and quality checks.

- Service and maintenance – The service BOM supports long-term maintenance, repair, and troubleshooting.

Throughout all of these stages, product BOM management acts as the connective tissue that ensures design, engineering, manufacturing, and service teams operate with synchronized data. When managed properly, the BOM creates seamless continuity across all domains.

But when it’s disconnected, that’s where problems begin.

Challenges of disconnected or siloed BOM management

Traditional product development environments often depend on spreadsheets, email chains, and static documents to manage BOMs, especially in engineering and manufacturing. These disconnected approaches introduce numerous challenges:

Multiple conflicting versions

Different teams create their own BOM versions, often resulting in:

- Outdated engineering data

- Misaligned manufacturing instructions

- Duplicate part numbers

- BOMs that don’t reflect the latest design changes

Misalignment between EBOM and MBOM

Engineering teams maintain an EBOM, while manufacturing relies on an MBOM. Without integration, these two often drift apart, leading to:

- Incorrect build instructions

- Costly scrap and rework

- Delayed production cycles

Difficulty managing product variants

With disconnected processes, BOM configuration becomes a manual, error-prone task. Supporting multiple customer variants, regional requirements, or product families becomes exponentially harder.

Poor traceability and change management

When changes occur like design updates, new supplier components, or compliance shifts, teams struggle to trace their downstream impact. This often leads to:

- Missed updates

- Quality escapes

- Longer engineering change cycles

Limited cross-functional visibility

Mechanical, electrical, software, and manufacturing teams often work with fragmented data, impairing collaboration and slowing development.

Disconnected, siloed BOMs introduce friction, risk, and inefficiency throughout the entire product development process. To overcome these pitfalls, organizations need modern, digitally connected practices.

Traditional vs. modern product BOM management

Modern product BOM management: driven by digital transformation

Moving beyond the traditional, fragmented approaches that lead to the challenges we’ve just explored, modern product BOM management represents a fundamental shift toward integrated, data-driven, and collaborative product development. It’s not just about digitizing data; it’s about connecting the entire product lifecycle through unified, intelligent workflows, transforming how BOMs are managed.

Instead of relying on isolated documents, organizations now leverage an integrated BOM management solution that maintains the BOM as a living, evolving dataset shared across all domains and teams. This digital backbone ensures real-time synchronization, allowing every stakeholder to work from a single source of truth. This eliminates version confusion, significantly reduces risk, lowers costs, and fundamentally accelerates development.

When applied to product BOM management, digital transformation delivers:

- Real-time, cross-domain collaboration: Fostering seamless communication and shared understanding across mechanical, electrical, electronic, and software engineering teams, as well as with suppliers and manufacturing partners.

- Automated propagation of design updates: Ensuring that changes are instantly reflected and traceable throughout the entire product lifecycle, from initial design to service.

- Comprehensive traceability and change management: Providing a clear audit trail for all modifications and their impact.

- Robust support for complex product architectures and variants: Streamlining the management of diverse product families and configurations through embedded BOM configuration rules.

- Data continuity across the digital thread and digital twin: Ensuring a consistent flow of information from design to operation.

- Greater overall design and manufacturing efficiency: Empowering teams to develop higher-quality products faster and more sustainably.

This holistic approach empowers teams to develop higher-quality products faster and more efficiently.

Siemens stands out as a leader in enabling this integrated BOM management through its Accelerated Product Development digital thread, which connects every step of the lifecycle.

With the foundation in place, organizations can take the next step: sustainable engineering.

Integrated BOMs and sustainable product engineering

Sustainability is no longer optional, but rather a defining factor in product competitiveness. An integrated product BOM supports sustainability by offering complete visibility into material choices, compliance requirements, environmental impact, and end-of-life strategies.

5 ways integrated BOMs support sustainability

- Material transparency: Track carbon impact, hazardous substances, recyclability, and supplier data.

- Circular design strategies: BOM visibility aids in planning for reuse, refurbishment, and recycling.

- Compliance automation: Integrated tools manage regulations like RoHS, REACH, and company-specific standards.

- Energy-efficient component selection: Teams can compare options based on environmental performance.

- Lifecycle assessment (LCA): Accurate BOM structures allow early integration of LCA analysis.

Siemens’ PLM software and digital thread technology makes sustainable product development measurable and traceable, helping product teams design responsibly without compromising performance or innovation.

Conclusion

As products grow more intricate and customer expectations rise, organizations must break away from outdated, disconnected methods of managing BOM data. Traditional spreadsheets and siloed systems cannot keep pace with modern engineering complexity, sustainability requirements, or global collaboration.

Digital transformation is the path forward.

The ability to maintain a single source of truth across multiple domains is now indispensable. Integrated BOMs reduce risk, improve quality, accelerate development, and empower teams to innovate sustainably.

Siemens’ holistic ecosystem, including its Accelerated Product Development digital thread, provides the digital foundation needed to manage BOMs seamlessly across the entire lifecycle. By embracing digital transformation today, organizations are better equipped to design smarter, build faster, and deliver more sustainable products—meeting the demands of tomorrow’s market with confidence.

FAQs about product BOM management

How does product BOM management accelerate product development?

By making the BOM the canonical data model, changes propagate automatically to downstream artifacts (mBOMs, ERP, service documentation). This eliminates manual reconciliation, enables concurrent engineering (teams make decisions simultaneously rather than sequentially), and allows manufacturability validation earlier in the design phase. The result is faster iteration cycles, fewer surprises, and more predictable schedules.

What is a multidomain BOM and how does it differ from simple eBOM/mBOM lists?

A multidomain BOM is a single, linked graph representing parts, software modules, and service items as nodes with typed relationships. Discipline views (eBOM, mBOM, sBOM) are derived on demand from this canonical model. The key difference is that multidomain BOMs emphasize cross-domain traceability, effectivity logic, and configuration semantics—not isolated static lists. Changes propagate automatically across all views, and variant logic is enforced consistently.

Why do traditional BOM management methods fail to support today’s complex products?

Conventional methods—such as spreadsheets, domain-specific databases, or unlinked ERP exports—cannot maintain synchronization across mechanical, electrical, and software domains. Each change must be manually reconciled, often leading to version drift, outdated part lists, and misaligned product definitions. As connected products, modular architectures, and embedded software grow in complexity, the inability to manage interdependencies causes downstream production issues, costly rework, and slower time to market.

How does product BOM management enable continuity across the digital lifecycle?

Effective product BOM management links every phase of the lifecycle—from requirements and concept through design, manufacturing, and service—via a consistent digital thread. Each BOM view (eBOM, mBOM, sBOM) is derived from the same master model, ensuring that design changes propagate automatically and remain traceable. This digital continuity minimizes data silos, reduces engineering change order (ECO) delays, and provides the transparency needed for agile, data-driven decision-making.