The Supply Chain Control Tower Revolution: Why Visibility Alone Is No Longer Enough

Your shipment is delayed. Again. Your control tower sent an alert, but by the time you read it, the damage was done. Your customer is demanding answers you don’t have. Your team is firefighting instead of strategizing. Sound familiar?

If you’re managing supply chain operations in 2025 (or anytime recently), you’ve lived this frustration. Control towers have become the industry standard for visibility, yet 80% of organizations still lack fully implemented visibility platforms. The ones that do have visibility are drowning in alerts while starving for actionable intelligence.

But here’s what’s separating supply chain leaders from the laggards: They’re not just seeing problems—they’re solving them automatically.

The $20 billion question no one is answering correctly

The numbers reveal a stark reality. The global Supply Chain Control Tower market is projected to reach $20 billion by 2030, growing at 13.12% CAGR (Compound annual growth rate). Yet despite this massive investment, most organizations are still operating control towers stuck in reactive mode.

Traditional control towers are like having a security camera that shows the burglary in progress but can’t lock the doors. By the time you receive an alert, shipments are already delayed, costs are already escalating, and customers are already unhappy.

The industry desperately needed evolution, not just improvement. Instead of better dashboards, leaders are building something fundamentally different:

Autonomous decision-making platforms that think, predict, and act.

Meet the cognitive revolution that’s already happening

This isn’t another “digital transformation” story. This is about AI-powered control towers that are already transforming supply chains from reactive cost centers to proactive competitive weapons.

ABI Research and Siemens Digital Logistics have partnered to decode the evolution from basic visibility to cognitive control towers. While traditional platforms stick to tracking shipments, this next generation delivers supply chain intelligence that operates like a strategic command center from 2030.

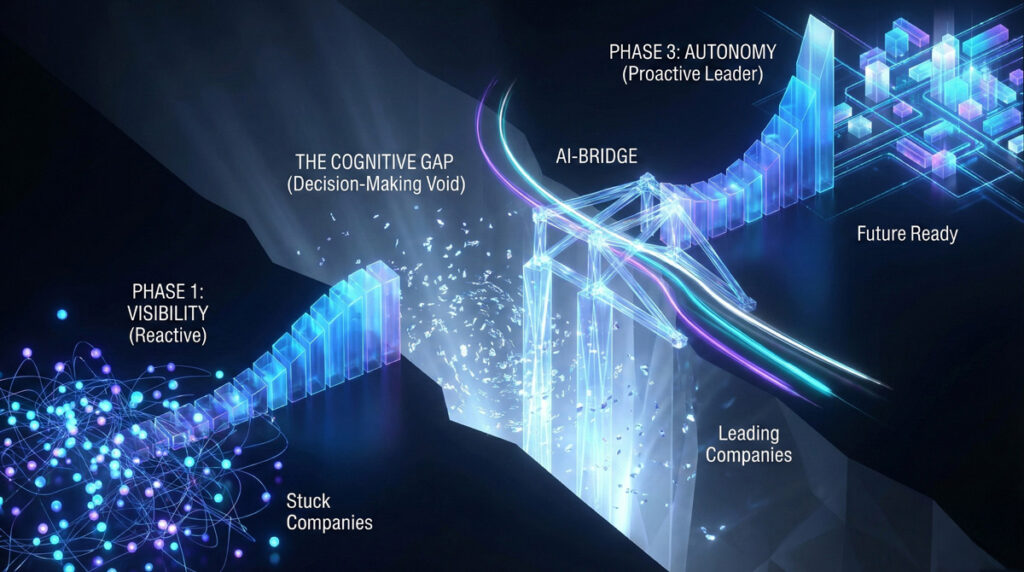

The maturity curve most companies are getting wrong

The journey from visibility to autonomy isn’t a straight line—it’s a maturity curve most organizations are misreading. Here’s where the industry actually stands:

80% still building basic visibility foundations

60% haven’t implemented digital twins

70% can collect data in near real-time, but only 40% can perform predictive or prescriptive analytics

The gap between data collection and decision-making is where competitive advantage lives.

Cognitive control towers close this gap by moving through three critical phases:

Phase 1: Visibility (Where most companies stop)

Real-time tracking, centralized data, alert-based monitoring

Phase 2: Forecasting & Alerts (Where leaders differentiate)

Predictive analytics, what-if scenarios, exception management

Phase 3: Autonomous Decision-Making (The new competitive battlefield)

Prescriptive analytics, automated controls, self-healing supply chains

The three capabilities that define cognitive control towers

While competitors debate whether to upgrade their visibility platforms, cognitive control towers are already delivering three revolutionary capabilities:

1. Predictive Intelligence That Prevents Problems

Machine learning algorithms analyze not just your shipments, but 200+ external data signals including:

- Real-time vessel positioning and port performance

- Marine weather patterns and adverse climate tracking

- Macroeconomic indicators and bunker fuel impacts

- Carrier schedule changes and blank sailings

- Supplier risk data and geopolitical disruptions

The result? AI that doesn’t just tell you your container is delayed—it tells you it will be delayed 72 hours before it happens, explains why, and suggests three alternative solutions.

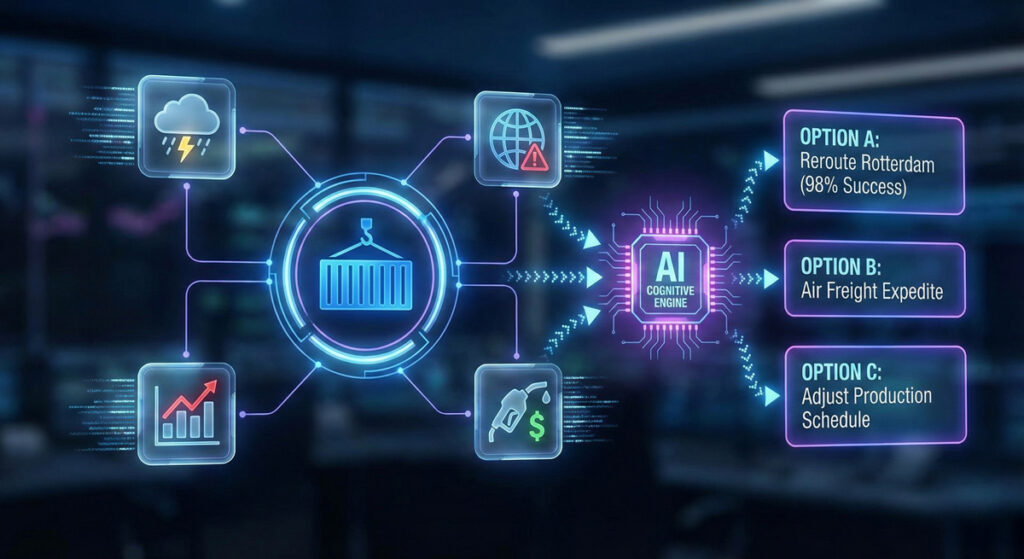

2. Autonomous Decision-Making That Executes Solutions

Traditional control towers create work. Cognitive control towers complete it.

When the system predicts a 3-day delay at Hamburg port due to 85% yard utilization, it doesn’t just alert your planner. It:

- Automatically re-routes through Rotterdam if capacity is available

- Updates ETAs across all customer communications

- Adjusts downstream production schedules in your ERP

- Negotiates alternative carrier rates through integrated procurement

- Learns from the disruption to improve future routing decisions

3. Management by Exception That Frees Your Experts

Most supply chain teams are brilliant strategists trapped in tactical firefighting. They monitor thousands of shipments when they should be optimizing network design.

Cognitive control towers flip this dynamic. They automatically manage 95% of shipments while surfacing only the exceptions that truly need human expertise—along with context, impact analysis, and recommended actions.

Your team stops being reactive traffic controllers and starts being proactive value creators.

The real-world impact that makes CFOs demand implementation

Let’s talk quantified results that matter to your executive team and board:

Operational efficiency that compounds:

- 80% reduction in manual updates and data chasing—Your planners become strategists, not investigators

- 15% decrease in detention and demurrage charges—AI prevents the expensive surprises that destroy quarterly margins

- 5% reduction in expedited freight costs—Predictive visibility means fewer emergency shipments and premium freight

Strategic advantages that differentiate:

- Customer confidence when you proactively communicate solutions instead of explaining problems

- Inventory optimization based on predictive ETAs rather than hope-based planning

- Competitive moats when your supply chain reliability becomes a market advantage competitors can’t match

The integration reality most AI solutions ignore

The dirty secret of most “revolutionary” supply chain solutions? They create more work through fragmented interfaces and isolated data silos.

Siemens’ AX4 platform changes this paradigm fundamentally.

Cognitive intelligence doesn’t live in another dashboard your team must remember to check. The predictive insights, autonomous recommendations, and exception alerts flow directly into your existing workflows, ERP systems, and communication channels.

Over 500,000 users already access this best-in-class intelligence seamlessly integrated into their daily operations. The AI becomes part of your team, not another system competing for attention.

The competitive gap that widens every quarter

The cognitive control tower market isn’t emerging—it’s already a $20 billion reality growing at double-digit rates. Leading manufacturers, automotive companies, and industrial enterprises are implementing autonomous decision-making capabilities across their global supply chains.Abstract-for-SCCT-Webinar.docx

Every quarter you delay adoption, competitors gain intelligence you’re missing. Every disruption they predict and prevent while you react to widens the performance gap permanently.

The question isn’t whether cognitive control towers will transform supply chain operations—they already are. The question is whether you’ll lead that transformation or spend the next five years catching up.

The knowledge gap you can close in 60 minutes

You’re facing a fundamental choice: Continue investing in incrementally better visibility, or leapfrog to autonomous decision-making.

The right answer depends on understanding:

- Where your organization sits on the maturity curve right now

- Which adoption barriers will derail your implementation (and how to overcome them)

- How to evaluate providers beyond feature checklists

- What specific steps move you from reactive to proactive to autonomous

You could spend six months and hundreds of thousands of dollars figuring this out through trial and error. Or you could get the strategic blueprint in one hour.

Join the webinar that maps your path to autonomy

ABI Research Principal Analyst Ryan Wiggin is sharing the exact maturity framework, evaluation criteria, and implementation roadmap his firm developed through analyzing hundreds of control tower deployments.

This isn’t vendor marketing. This is independent research-backed strategic intelligence that typically costs enterprise clients tens of thousands of dollars.

In this exclusive webinar, you’ll discover:

- The precise maturity curve position of 80% of enterprises (and why most self-assessments are wrong)

- The five adoption drivers accelerating SCCT investments right now

- The hidden barriers causing 60% of implementations to underdeliver (and how to avoid them)

- A provider evaluation framework that prioritizes long-term autonomy over short-term features

- Actionable recommendations to move from visibility to autonomous decision-making in 12 months

The cost of waiting another quarter

Your supply chain disruptions aren’t going away. They’re accelerating. Customer expectations aren’t relaxing. They’re intensifying. Competitive pressure isn’t decreasing. It’s compounding.

Every month you operate in reactive mode is another month of:

- Margin erosion from preventable expediting costs

- Customer churn from communication failures

- Team burnout from endless firefighting

- Competitive disadvantage from slower response times

The organizations that will dominate the next decade are already building cognitive supply chains. The only question is whether you’ll join them or compete against them.

Register now: Your autonomous future starts with one decision

Date: December 16, 2025

Time: 10 am ET | 4pm CET

Duration: 60 minutes (including live Q&A)

Investment: One hour of your time. Return: A strategic roadmap to supply chain autonomy.

Can’t attend live? Register anyway—everyone who registers receives the recording, presentation slides, and executive summary within 24 hours.

For the skeptics and the believers

Whether you’re convinced cognitive control towers are the future or think they’re overhyped vendor promises, this webinar will give you the independent data to make informed decisions.

You’ll leave with:

- ABI Research’s proprietary maturity assessment tool

- Provider evaluation scorecard

- Implementation phase checklist

- 90-day action plan template

The supply chain leaders of 2030 are making the decisions today that will define their competitive position. Make sure you’re one of them.

About ABI Research

ABI Research is a global technology intelligence firm delivering actionable research and strategic guidance to technology leaders, innovators, and decision makers. Their Supply Chain Control Tower competitive ranking and implementation research is the industry’s most comprehensive analysis of adoption trends, vendor capabilities, and ROI frameworks.

About Siemens Digital Logistics

Siemens Digital Logistics provides cloud-native supply chain solutions that enable enterprises to achieve end-to-end visibility, predictive analytics, and autonomous decision-making. Recognized as a Leader and Top Implementer in ABI Research’s Supply Chain Control Tower rankings, Siemens partners with clients to transform supply chain operations from reactive cost centers to proactive competitive advantages.

More resources:

- Download the Supply Chain Resilience Whitepaper

- Read: When Sea Freight Gets Smarter

- AX4 Real-Time Transportation Visibility Fact Sheet

Questions? Contact our webinar team at webinar@siemens.com