How to short-circuit supply chain bottlenecks

Supply chain bottlenecks have become the norm. How is it possible to reliably satisfy the demand for electronic components?

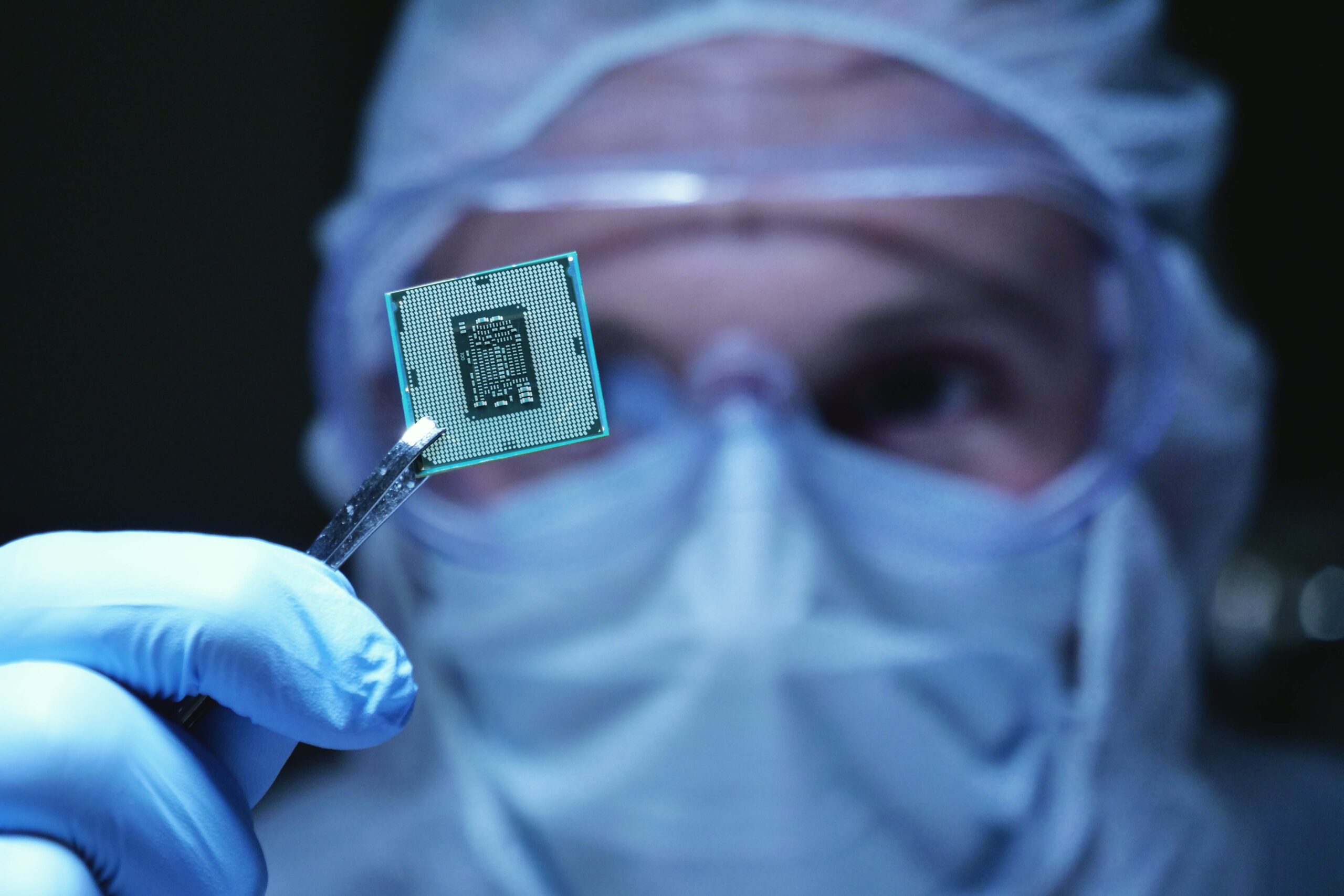

Electronics manufacturers see a growing need for a reboot: The components they urgently need are caught up in congested supply chains. Customer orders cannot be filled. Supply chain bottlenecks have become the norm. What’s really creating headaches is the semiconductor crisis, as manufacturers find it increasingly difficult to obtain microchips from East Asia and the US.

There are many factors are driving this trend: Natural disasters, geopolitical tensions, trade wars, and other irregularities in the globally intertwined procurement network are upending the delicately balanced structure.

In times of economic stress, manufacturers and other market players ask themselves tough questions: Are just-in-time deliveries still possible? How much will it cost to boost inventories? Does it make sense to keep offshoring production? How is it possible to reliably satisfy the demand for electronic components?

Using technology to power up logistics networks

The more light is shed on the procurement situation and the more transparent the interrelationships and dependencies in the supply chain become, the sooner manufacturers will be able to shore up their market and make production profitable.

Digital models and tools are indispensable for supply chain management in the electronics and semiconductor industry. They deliver the data streams that keep processes under control. They help make inbound and outbound supply chains more transparent and resilient, paving the way for profitability.

Digital platform solutions such as cloud-based control towers serve as a motherboard for your logistics, a centralized interface to all stakeholders needed to ensure a smooth supply chain. Suppliers, OEMs, manufacturers, logistics service providers, freight forwarders, customs authorities, and service partners: All the players involved in the production and supply process are integrated and synced, regardless of the IT systems they use in house. Workflows are standardized and processes work together seamlessly. This ensures that even sensitive components reach your customers.

Download related whitepapers

Green light for success

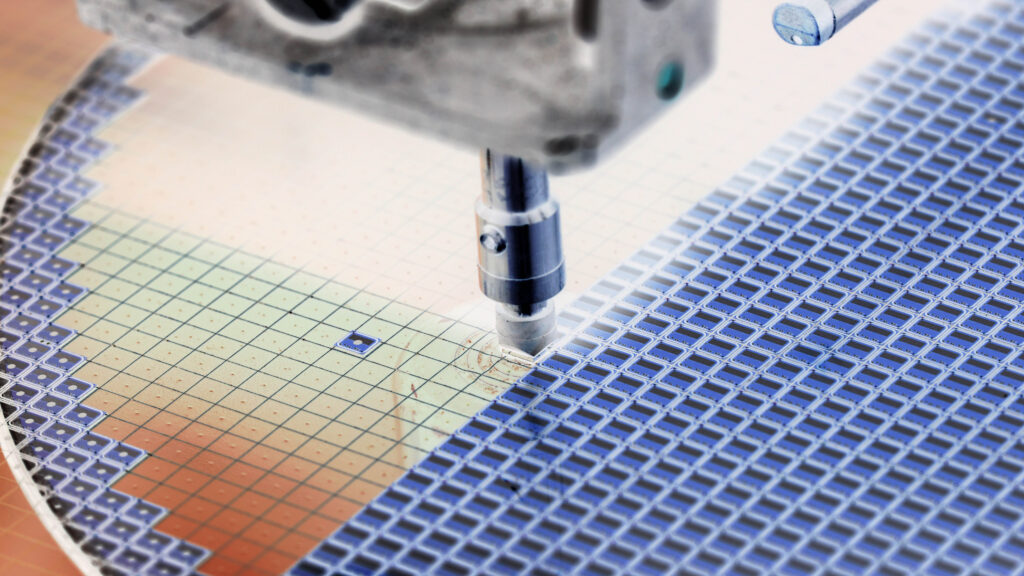

Can success in the electronics and semiconductor industry be planned? From a logistics perspective, the answer is a clear “yes”! That’s because planning and simulation tools such as the digital twin are now so sophisticated that businesses can analyze alternative courses of action in advance.

What changes to the supplier network are needed to ensure a successful go-to-market? How can you navigate around the problems of one supplier? How can transport and logistics processes be optimized for efficiency and sustainability?

These IT tools help shine a light on every conceivable scenario or risk in the supply chain and accurately assess their impact on the overall process so that goods can flow easily.

The electronics and semiconductor industry has undoubtedly recognized the need for a sustainable and resilient supply chain. Siemens Digital Logistics has the right mix of industry savvy and technological expertise to deliver the digital logistics solutions your company needs.