Turning shop-floor insights into competitive edge in food & beverage manufacturing

Every production line tells a story — in numbers, patterns and signals. For food and beverage manufacturers, the challenge is not the lack of data, but knowing how to turn it into decisions that improve performance, ensure quality and meet sustainability goals.

By incorporating Artificial Intelligence (AI), Machine Learning (ML), the Industrial Internet of Things (IIoT), edge computing and advanced automation into production execution, this transformation is within reach. Data, when captured in real time, contextualized, and acted upon, becomes the foundation for agile, intelligent manufacturing. Siemens’ Smart Manufacturing solutions make this possible through a structured, data-driven continuous improvement approach.

Download “The true value of manufacturing data” for a deeper dive into these strategies.

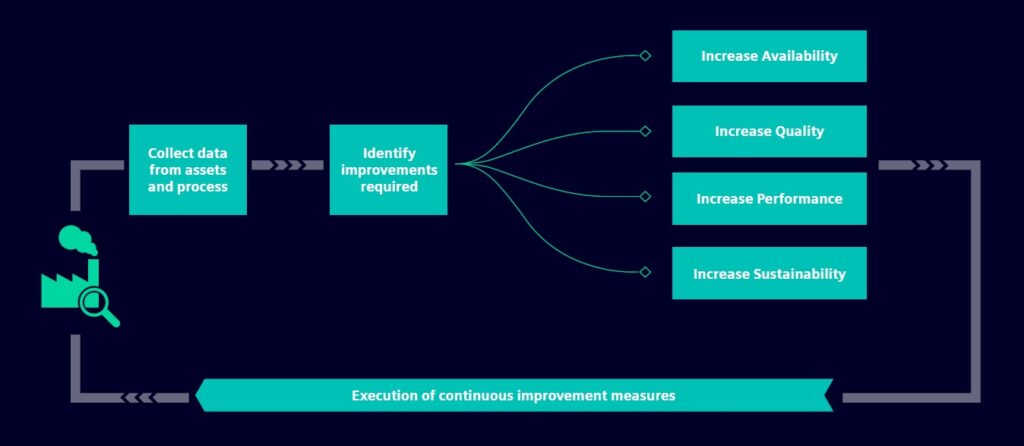

The continuous improvement loop

Using the DMAIC framework — Define, Measure, Analyze, Implement, Control — manufacturers can transform data into targeted actions. Siemens’ approach combines operational expertise with advanced analytics to create measurable impact.

Five core applications drive this process:

- Measure overall equipment effectiveness (OEE)

OEE provides a precise view of availability, performance and quality. Backed by IIoT data, it pinpoints the most critical areas for improvement and validates the results of corrective measures. - End-to-end predictive maintenance to avoid downtime

Leveraging historical and real-time asset data, predictive models identify the optimal time for intervention. This prevents costly breakdowns and extends equipment lifespan. - Quality prediction before the end of the line

Machine learning models anticipate deviations early, allowing production teams to correct issues before they impact output. This reduces waste and speeds product release. - Digital twin for performance optimization

Linking live data to a digital twin of the production line reveals bottlenecks and tests solutions without interrupting operations. - Data-driven sustainability

Energy and resource usage data can be analyzed alongside productivity metrics to drive efficiency improvements that align with sustainability objectives.

Scaling for maximum impact

When successful in one facility, these solutions can be replicated across multiple plants and regions. Siemens’ flexible IT/OT integration ensures compatibility with both new and legacy systems, while a unified data model supports consistent benchmarking.

Future-ready manufacturing

According to Gartner, companies that embed data-driven methodologies achieve greater agility and real-time optimization. For food and beverage producers, this is not just an operational advantage — it’s a strategic necessity.

Siemens’ data-driven continuous improvement solutions combine the real and digital worlds to help manufacturers achieve higher productivity, consistent quality, and measurable sustainability — creating lasting competitive advantage.