Optimize food and beverage production: Try our MTP standardized line automation free trial

In the fast-paced world of food and beverage production, scaling production to meet rising consumer demands is a critical challenge. Manufacturers must integrate new equipment seamlessly into their production lines while balancing the need for speed, flexibility, and quality—all without disrupting operations.

With Siemens’ standardized line automation module type package (MTP) approach, you can automate equipment integration and reduce engineering effort by up to 70%. Combined with digital twin technology, this trial allows you to virtually commission new equipment, cutting down downtime and minimizing risks associated with manual setups.

In this blog, we’ll break down:

- How the trial works

- Who the trial is most useful for

- What you’ll get out of your time investment

- What scenarios are covered in the trial

Why MTP? The key to faster, safer equipment integration

The MTP trial will show you how Siemens’ tools make it easier to integrate new machinery into your production line by leveraging standardized line automation. You’ll also explore how to validate new equipment performance in a virtual environment before implementation, ensuring minimal disruption to your operations and faster time to market.

Who should use the MTP trial?

This solution trial focuses on two key user roles in the food and beverage industry:

Manufacturing Engineer:

- Optimizes production processes by integrating new equipment into existing production lines.

- Validates equipment specifications and ensures seamless integration of machinery with SCADA systems.

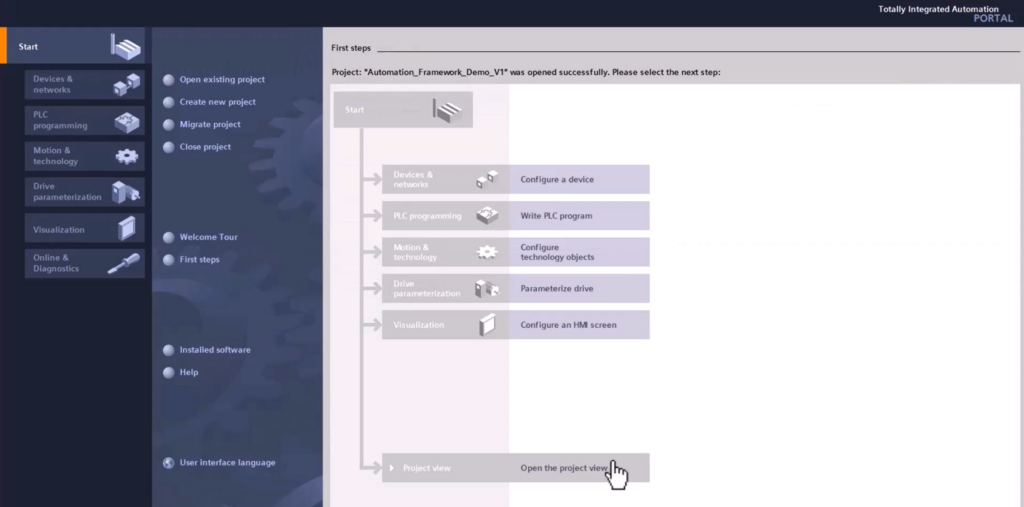

- Uses TIA Portal to automate configurations, reducing manual setup time and minimizing errors.

Automation Manager:

- Leads the implementation of automation technologies within production lines to improve efficiency.

- Monitors equipment performance and ensures compliance with safety and operational standards.

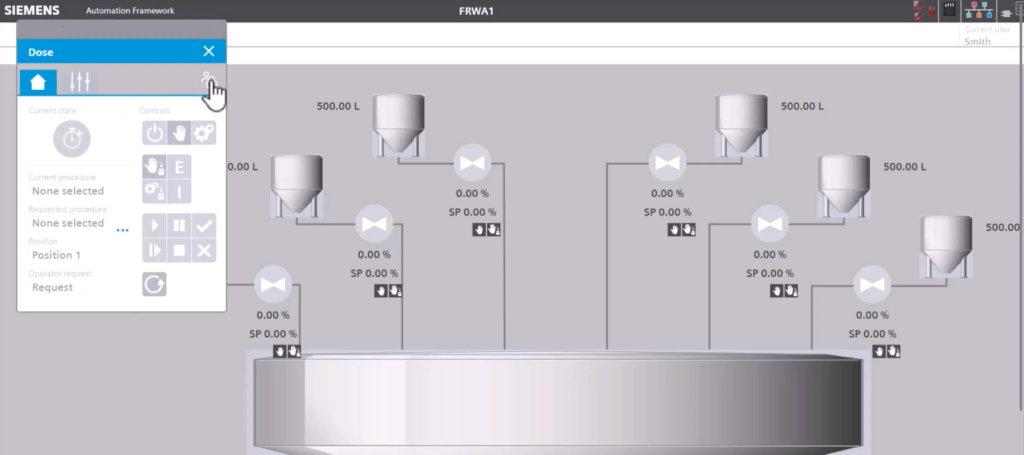

- Uses WinCC Unified for real-time monitoring and control during virtual commissioning and testing.

What will you get from the standardized line automation MTP trial?

Manufacturing Engineer: Streamlining Equipment Integration

- Explore how to add a new multi-dosing station to your production line using TIA Portal.

- See how automated setups save time and reduce errors, ensuring efficient integration with SCADA systems.

Automation Manager: Minimizing Downtime

- Learn how to simulate and validate equipment performance in a digital twin environment, minimizing disruptions.

- Optimize equipment setup by comparing sequential and parallel dosing operations.

How does the standardized line automation MTP trial work?

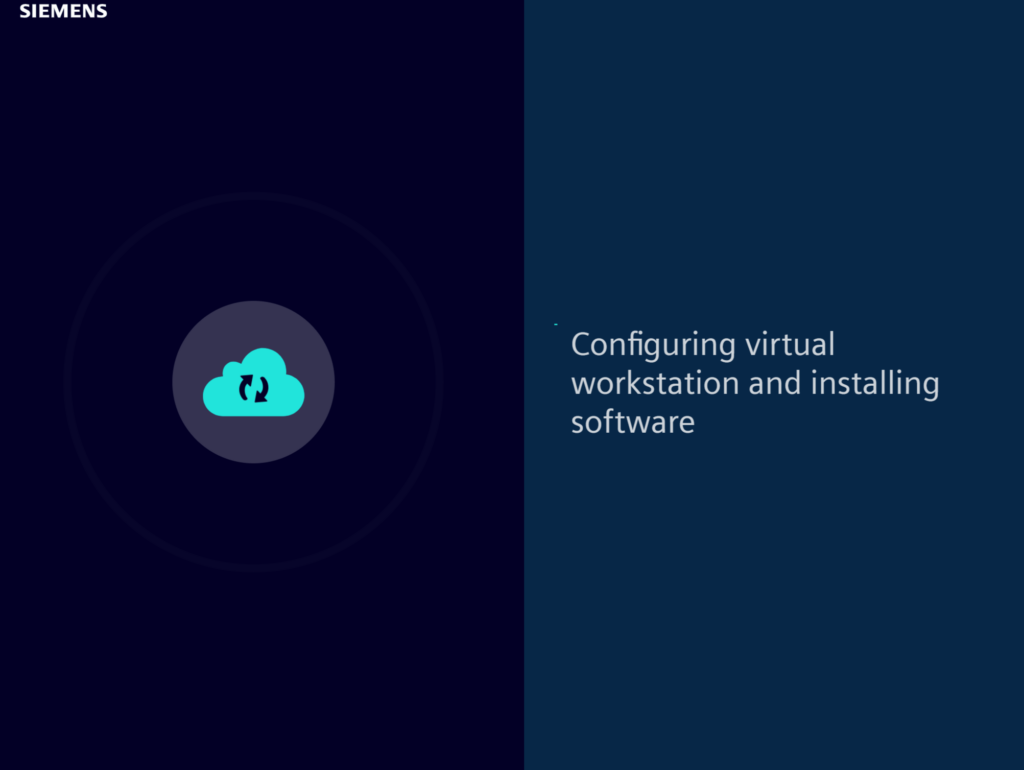

First, the demo configures your virtual environment to simulate the setup you’ll be using. You’ll then choose a scenario and follow on-screen prompts guiding you through equipment integration and commissioning.

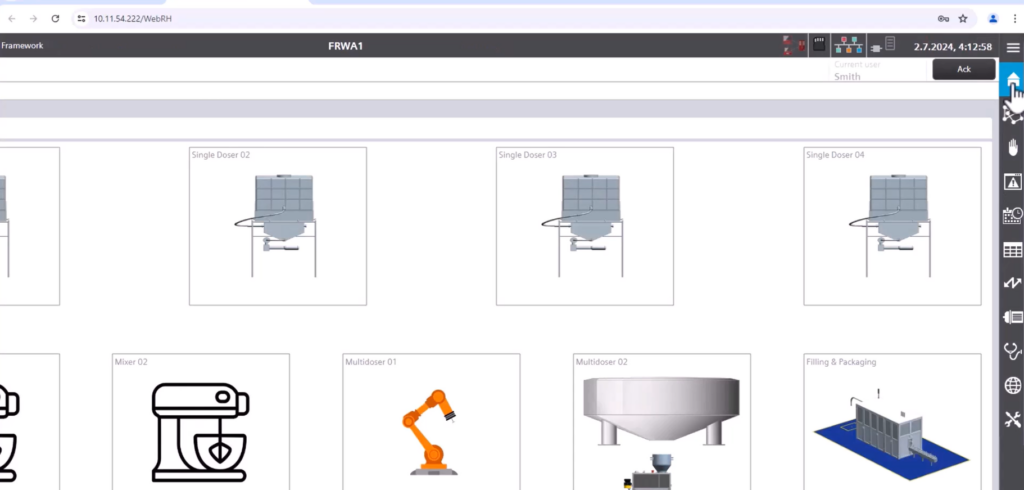

Next, you’ll be able to select which scenario you’d like to explore and get more details on what you’ll experience in each section.

The demo will give on-screen prompts guiding you through each step of the experience, helping you understand how MTP automation can streamline the equipment integration process.

In this scenario, you’ll see a visual walk-through of how to add new equipment—such as a multi-dosing station—to your production line, and how the TIA Portal automates the setup, saving you time and minimizing manual errors.

Act 1: Equipment integration

You will start by selecting Act 1, where you will learn how to:

- Use TIA Portal to automate equipment configurations and cut down on manual work.

- Integrate new machinery into the existing SCADA network effortlessly.

- Optimize equipment performance and monitor it in real-time with WinCC Unified.

This walk-through will take you step by step through the process, showing how you can streamline complex equipment integration tasks.

Act 2: Virtual commissioning

Next, you’ll dive into Act 2, focusing on virtual commissioning. This simulation allows you to validate new equipment before implementation, ensuring minimal downtime and error-free performance.

- Step 1: Set up the equipment using a digital twin to simulate real-time performance.

- Step 2: Validate the configuration, ensuring that everything runs smoothly before going live.

You’ll see on-screen prompts that guide you through each action, ensuring the process is seamless and easy to follow.

Experience the benefits for yourself: Sign up for the free 30-day standardized line automation MTP trial

If you’re looking to optimize your food and beverage production and minimize downtime, the Standardized Line Automation MTP trial is your opportunity to see the benefits firsthand.

No downloads or installations required—start exploring in minutes and see the benefits firsthand.

Don’t miss out on this opportunity to streamline your operations—sign up today and start your MTP trial!