Accelerate EV development with comprehensive design and simulation

Electrify the future of automotive with vehicle electrification solutions

The electric vehicle (EV) market is experiencing rapid growth, fueled by increasing consumer demand for sustainable and efficient transportation.

As competition intensifies, manufacturers must innovate and introduce new features to attract customers. This requires a multidisciplinary design approach integrating various engineering disciplines to optimize vehicle performance, range, and cost.

This blog post will explore how comprehensive design and simulation tools can help you accelerate EV development and stay ahead of the competition. We will delve into the challenges faced by EV manufacturers, the benefits of a multidisciplinary approach, and the critical features of effective vehicle electrification solutions.

By leveraging advanced simulation technologies, you can optimize your EV design, reduce development time, and deliver innovative products that meet the market’s evolving needs.

Overcoming the challenges facing EV manufacturers for a greener future

As the EV market continues to grow, manufacturers face increasing pressure to meet consumer demands for range, features, and affordability while accelerating time-to-market.

To achieve these goals, EV manufacturers must adopt a comprehensive design and simulation approach that can help them overcome the challenges associated with vehicle electrification.

One of the biggest challenges facing EV manufacturers is developing innovative new features that differentiate their products from competitors. By adopting a multidisciplinary design approach, manufacturers can successfully incorporate complex systems and features while ensuring that their vehicles meet the highest quality and safety standards.

In addition to meeting consumer demands, EV manufacturers must accelerate their time-to-market to remain competitive. This can be challenging, as engineering new technologies and complex features often requires significant time and resources.

By leveraging advanced design and simulation tools, manufacturers can streamline their development processes and reduce the time it takes to bring new vehicles to market.

EV manufacturers must also address the challenges associated with cost and sustainability. To make EVs more affordable and accessible to a broader range of consumers, manufacturers must focus on reducing costs while ensuring their vehicles are environmentally friendly. This can be achieved through innovative design and manufacturing processes and using sustainable materials and technologies.

By addressing these challenges and adopting a comprehensive design and simulation approach, EV manufacturers can position themselves for success in the rapidly evolving electric vehicle market.

Comprehensive design and simulation solutions for EVs

EV manufacturers’ challenges require innovative approaches to accelerate development, ensure product quality, and meet market demands. Comprehensive design and simulation solutions offer a powerful toolkit to address these challenges effectively.

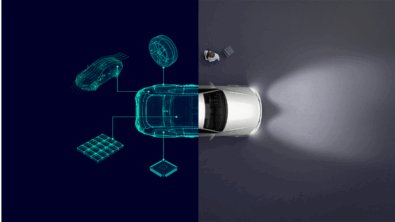

Manufacturers can foster collaboration among teams, optimize designs across various domains, and ensure seamless integration of complex systems by adopting a collaborative virtual engineering environment and a multidisciplinary design approach.

This approach enables early identification of potential issues, reduces physical prototyping, and accelerates time to market.

Frontloading decisions is also crucial for building designs that are right the first time. Manufacturers can minimize costly rework and avoid delays by leveraging simulation tools to evaluate design alternatives and optimize performance early in the development cycle.

Comprehensive design and simulation offer automotive manufacturers the ability to:

- Streamline processes, reduce physical prototyping, and bring products to market faster.

- Optimize designs, identify potential issues early, and ensure compliance with regulations.

- Foster teamwork and knowledge sharing across engineering disciplines.

- Minimize rework, avoid costly physical testing, and optimize resource allocation.

- Make data-driven decisions based on accurate simulations and analysis.

The key features of comprehensive design and simulation in EV development

Comprehensive design and simulation solutions are essential for the successful development of EVs. These solutions enable manufacturers to accelerate innovation, optimize vehicle attributes, deliver safe and sustainable vehicles, and create a collaborative virtual engineering environment.

By adopting a multidisciplinary design approach, manufacturers can rapidly innovate electric propulsion systems and new features. This approach allows for the efficient integration of complex systems, driving innovation in the EV market.

Balancing vehicle attributes is essential for optimal range, performance, and comfort. Comprehensive design and simulation solutions enable engineers to optimize weight, power consumption, thermal characteristics, and NVH.

This optimization ensures that EVs meet the desired range, performance, and comfort standards.

Delivering safe, affordable, and sustainable electrified vehicles is a critical goal. Through rigorous simulation and validation, manufacturers can ensure that their EVs adhere to safety standards, are built cost-effectively, and contribute to a more sustainable future.

Comprehensive design and simulation solutions facilitate a collaborative virtual engineering environment. This environment fosters efficient knowledge sharing and decision-making among engineering teams, streamlining the development process.

Adopting a multidisciplinary design approach is crucial for optimizing EV design across all systems. Manufacturers can ensure that the entire vehicle is designed holistically by considering multiple engineering disciplines, such as electrical, mechanical, performance, and embedded software.

Additionally, optimizing vehicle and part designs for weight reduction is essential for improving range and efficiency.

Comprehensive design and simulation solutions allow engineers to explore various materials and design options to achieve weight reduction without compromising performance.

Paving the way for a sustainable future with EVs

Comprehensive design and simulation solutions are pivotal in accelerating the development of EVs and shaping a sustainable future. By addressing the challenges faced by EV manufacturers, these solutions empower manufacturers to innovate, optimize, and deliver high-quality, affordable, and sustainable electric vehicles.

Manufacturers can efficiently incorporate complex systems and features through a multidisciplinary design approach, driving innovation in the EV market.

By balancing vehicle attributes such as range, performance, and comfort, manufacturers can meet consumer expectations and ensure a satisfying driving experience.

Comprehensive design and simulation tools also enable manufacturers to deliver safe, affordable, and sustainable electrified vehicles. Rigorous simulation and validation processes ensure that EVs meet safety standards, are cost-effective to produce, and contribute to a greener future.

A collaborative virtual engineering environment fostered by these solutions facilitates efficient knowledge-sharing and decision-making among teams of engineers.

By adopting a multidisciplinary design approach and optimizing vehicle and part designs for weight reduction, manufacturers can enhance the range and efficiency of EVs. This not only benefits consumers but also contributes to a more sustainable transportation landscape.

Ready to drive EV development forward? Learn more about how comprehensive design and simulation solutions can help you accelerate time-to-market, optimize performance and range, and let you collaborate efficiently across teams.