Aircraft design – Part 3: Dynamic design and iterative optimization

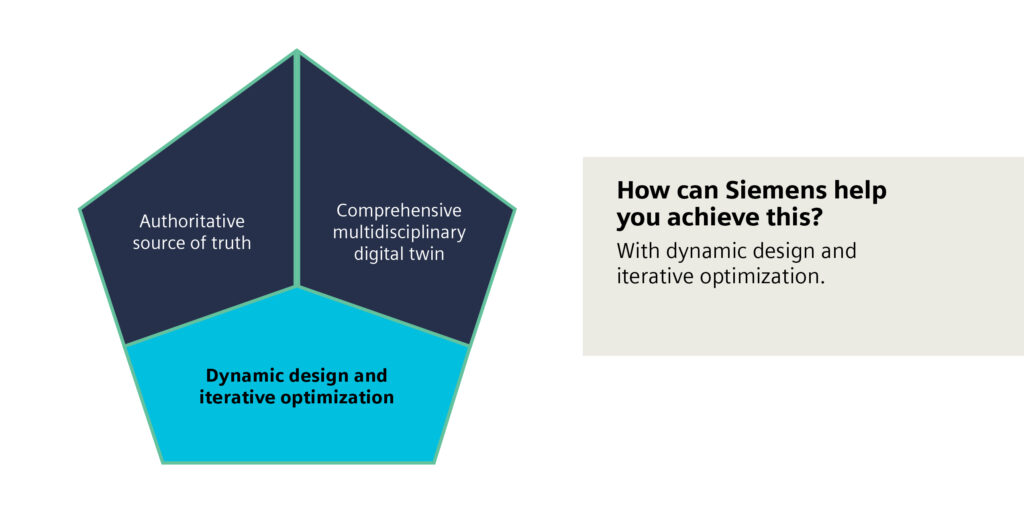

In the third and final part of our aircraft design series (be sure to catch up on part one and part two), the focus is on the third and final pillar of a multidisciplinary approach to aircraft design: Connecting design and simulation to achieve certified designs through an interdisciplinary, closed-loop design process.

Shift to dynamic design and iterative optimization for aerospace

As modern aircraft and spacecraft become increasingly complex, aerospace and defense companies need to shift from a static, document-based engineering process to a dynamic, model-based process. By making this shift, companies can:

- Empower collaboration across all disciplines

- Verify design performance

- Inspire innovation

- Adapt to ever-changing requirements

- Explore innovative materials

- Confirm product manufacturability

Embrace iterative processes in aircraft design

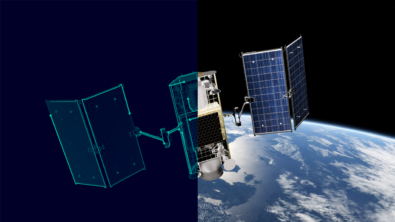

Simulation and optimization software allow design teams to analyze, understand and perfect every aspect of design. This is possible through the use of digital twins, which were discussed in part two of this series. Engineers can accurately predict all mission-critical performance aspects, optimize designs and innovate faster. From airframes and systems to innovative electric aircraft propulsion and combustion systems, teams can accurately model and optimize performance.

Siemens solutions for aerospace design

Our aerospace design solutions ensure that when requirements change, all aspects of a design can adapt simultaneously, reducing the impact of change. This allows you to integrate more innovation into designs while still meeting high performance standards. Plus, our solutions help you validate the impact of design modifications on product manufacturability and overall performance.

By combining dynamic design and iterative optimization with the other two pillars discussed in previous installments of this aircraft design series – establishing a single source of truth and leveraging a multidisciplinary digital twin – you can implement a multidisciplinary design and optimization (MDO) approach to aircraft design. This approach brings aircraft and spacecraft designs to market faster without compromising performance or opportunities for innovation.

To learn more about our aerospace design solutions, visit our resource hub page.

Did you miss the earlier installments of this series? Catch up on Part One: Establishing an authoritative source of truth and Part Two: Leveraging a multidisciplinary digital twin.