Why working with BEST means investing in the workforce of tomorrow

Board of Engineering Students of Technology (BEST) is soooo much more than just a student organization that fosters growth, learning, and friendship.

After working with Board of European Students of Technology (BEST) organizations across Europe since 2020, Siemens Digital Industries Software is proud to have continued this collaboration also in 2025. What we are seeing is that young minds tend to bring a more open and unconventional, sometimes even brave, mindset to the table, which is often a requirement for enabling innovations and new technologies to blossom—something that is also deeply embedded in Siemens’ DNA and engraved in our mission “Creating technology to transform the everyday, for everyone”.

So why is this collaboration so important?

When working with different BEST groups from different European countries and cities, we want to facilitate authentic learning experiences by encouraging students to work together on a project as a team, ideally in the same place. As we want the students to go beyond their comfort zone by learning and growing together by solving a real-life challenge in order to create a concrete impact, often connected to sustainability or green tech. On top of that comes the fun aspect of working together as a team and finding a joint solution. David Palencia, Vice-President for Services at BEST: “In all our events and workshops, we emphasize that teamwork is not only better for the team spirit, but also leads to better solutions as it reflects and benefits from different perspectives.”

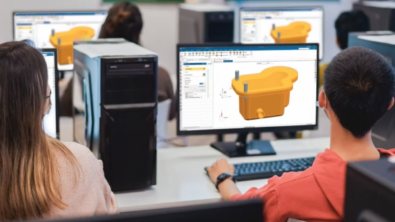

To visualize a vision or to test a solution for a dedicated problem, we offer and teach students professional software, as these competitions are also about enabling and preparing the younger generation for their future jobs. We want to show them how to prove their ideas with precise digital twins and prototypes, not only wage ideas put together with paper and pencil. We want them to design moving parts, simulate the flow of the water, print their prototypes or place them in virtual environments.

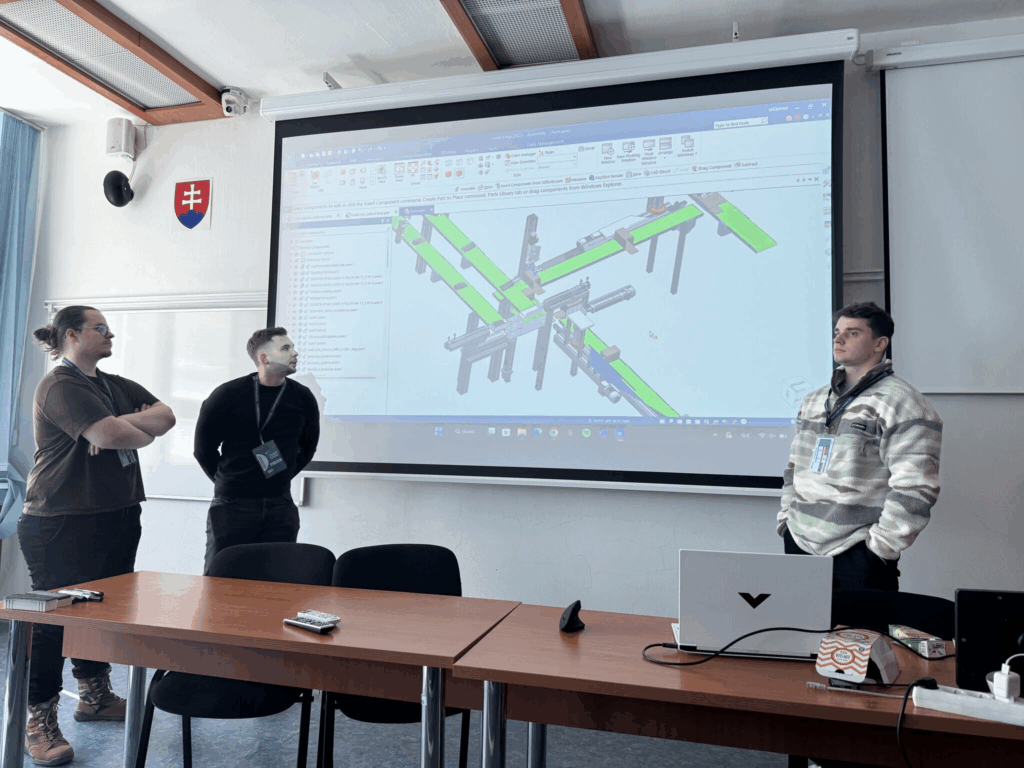

“Solid Edge is the perfect tool for these kinds of student challenges, offering the perfect level of professional functions to create a comprehensive digital twin of a dedicated solution and yet offer a good level of user friendliness,” says Donna Wright, Director Marketing and Academic Programs. As Solid Edge is an easy-to-learn and use software that also includes a comprehensive set of design tools in its Academic suite, students can usually take it on easily. “For enabling the students to be productive from the beginning on, we usually offer two training sessions, usually led by our Solid Edge Academic trainer Doug Stainbrook,” Wright continues. “In the last four years, I did several online training sessions for different BEST groups. Usually, I start with an introduction into the basics of Solid Edge, the second training is always connected to the specific challenge the students would receive from the org team.”

This year was also the first to test a train-the-trainer concept, as five students were sent for in-person training with Strainbrook to Erlangen. “This was extremely helpful, as we were able to dive deeper into the software and also ask dedicated questions to Doug.”

In total, seven competitions had been supported by Siemens throughout the year, beginning with the one in Erlangen and ending with the one in Lyon.

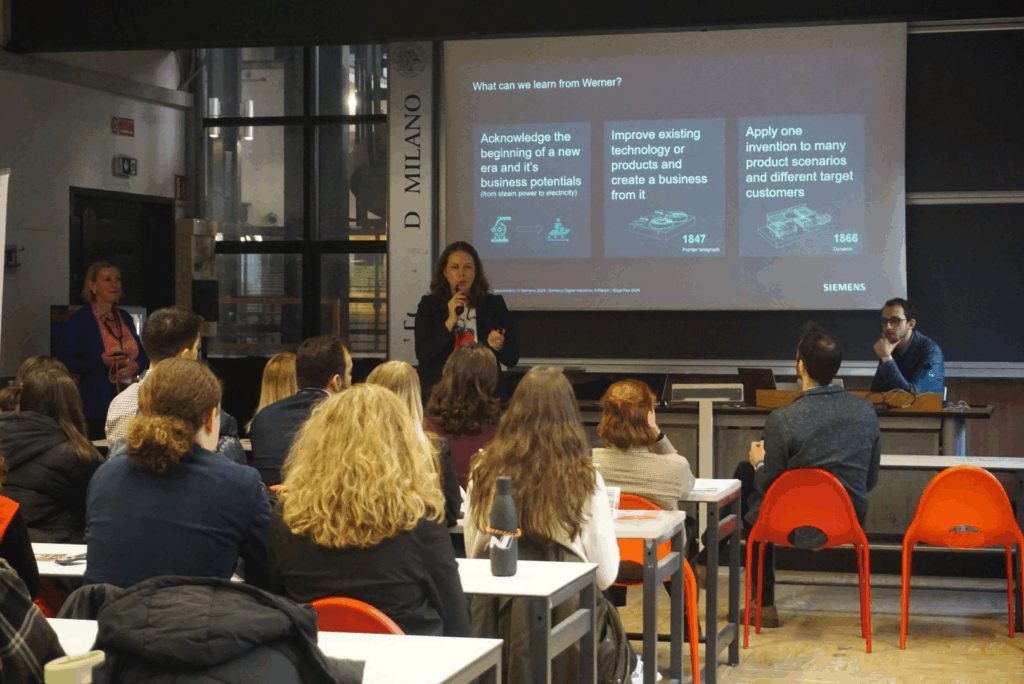

The French connection

In France, we were working together with BEST Lyon and BEST ENSTA Paris. “For us, it was important to bring together diverse perspectives to spark creativity and problem-solving”, says Pascal Devantine, CAD & Additive Manufacturing Portfolio Developer at Siemens Digital Industry Software.

Susann Kunz: “Whenever possible, we aim to set up real-life competitions involving real customers. We did this in the past already successfully by collaborating with customers like Hymer, Supfina, or Plastic Fischer.” This year, three of our competitions were supported and framed by customers. In Paris we were joined by AUUM, a company which has developed a machine to sanatize and streralize glases.

Get connected with a real Solid Edge customer in Kosice

Also in Kosice, Slovak we collaborated with one of our customers. MTS – Modern Technology Systems asked the students to design an assembly line for one of their beverages.