Training future marine engineers with Simcenter software at Hongik University

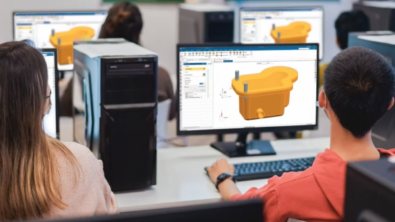

As part of efforts to prepare students for real-world challenges, the Smart Systems Engineering Lab (SSEL), led by Professor Yeon-Seung Lee at the Department of Naval Architecture and Ocean Engineering, Hongik University, integrates Simcenter STAR-CCM+ into key design courses.

With support from Siemens, students gain hands-on experience in CFD-based ship design and performance analysis.

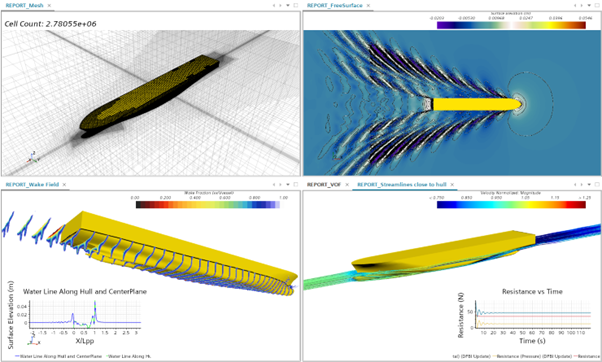

Through the Basic Ship Design course and their graduation project, students learn how to create hull forms and estimate resistance using the Hull Performance Workflow in Simcenter STAR-CCM+.

Even without prior CFD experience, they can easily simulate ship resistance through a guided and intuitive process—developing practical skills essential for the marine field.

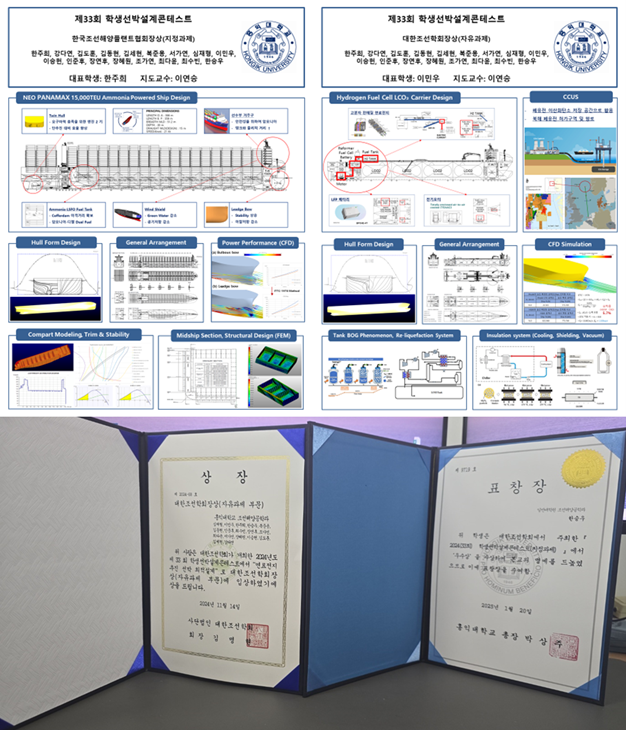

Hongik University wins dual awards at national ship design contest

At the 33rd student Ship Design Contest hosted by the Society of Naval Architects of Korea, two student teams from Hongik University’s Department of Naval Architecture and Ocean Engineering won prestigious awards under the guidance of Professor Yeon-Seung Lee.

For the designated task, the team developed a 15,000 TEU ammonia-fueled container ship, meeting future environmental standards through optimized hull form, structural design and performance analysis using Simcenter STAR-CCM+.

In the designated task, students developed a 15,000 TEU ammonia-powered container ship, using STAR-CCM+ to perform power performance analysis and resistance prediction through CFD simulations. These results supported hull optimization and validated propulsion efficiency.

In the open task, students designed a hydrogen fuel cell LCO₂ carrier and conducted CFD simulations with STAR-CCM+ to evaluate flow behavior and refine the integration of onboard systems, including CCUS technologies.

Both projects showcased the effective use of STAR-CCM+ and highlighted the impact of Siemens’ support in fostering real-world design capabilities among students.

Utilizing Simcenter software for advanced research at the Smart Systems Engineering Lab, Hongik University

At the Smart Systems Engineering Lab (SSEL) at Hongik University, a range of marine engineering research projects are being conducted using Simcenter software through the Siemens Academic Program. These studies cover areas such as onboard thermal management, safety analysis under emergency scenarios and aerodynamic evaluation of sustainable propulsion systems. By leveraging multi-physics simulation tools like STAR-CCM+ and AMESIM, the lab explores integrated approaches to complex design challenges in naval architecture and ocean engineering.

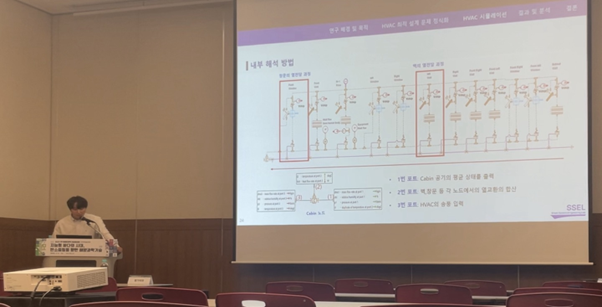

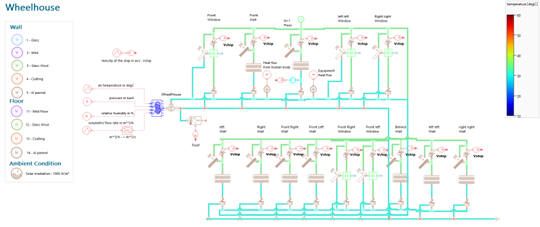

Onboard HVAC design using Simcenter STAR-CCM+ and AMESIM

SSEL performed HVAC optimization for the wheelhouse of an SMR-powered container ship using Simcenter STAR-CCM+ and Simcenter AMESIM. The research aimed to assess the impact of hull design and HVAC operation on cabin temperature and comfort, applying a multidisciplinary approach integrating 1D thermal system modeling and 3D CFD analysis.

The simulation included:

- Thermal system modeling with AMESIM: cabin air node modeling, wall/window heat exchange and HVAC input/output analysis.

- External and internal CFD with STAR-CCM+: external wind flow, radiation and convection modeling, SST k-ω turbulence model.

- Three geometric cases for wheelhouse structure. Optimization using NLPQL algorithm to determine airflow minimizing energy use by PMV/PPD-based comfort evaluation.

Key findings:

- The optimal case was selected based on the comparison of power consumption due to air resistance and HVAC supply airflow, choosing the scenario with lowest total energy demand.

CFD simulations revealed distinct temperature distribution patterns that could not be identified using AMESIM alone.

In thermal comfort analysis, the combined use of AMESIM and STAR-CCM+ provides a strategic approach to accurately assess HVAC performance and inform system design decisions.

This case demonstrates how students leverage Siemens tools to simulate onboard HVAC systems, quantify comfort performance and propose design enhancements in future-ready nuclear-powered vessels.

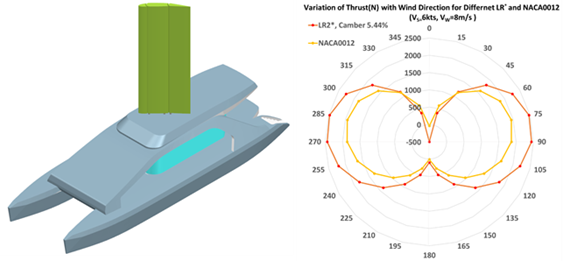

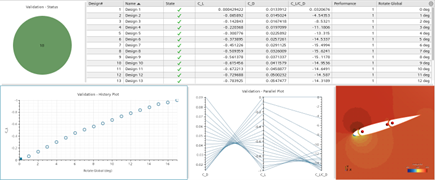

SSEL at Hongik University harnesses STAR-CCM+ Design Manager to optimize wind-assisted propulsion

SSEL led by Professor Yeon-Seung Lee, researched optimizing three-element wingsail aerodynamics for marine transport decarbonization. Using Siemens’ STAR-CCM+ software through their academic program, the team studied auxiliary propulsion optimization.

The team used STAR-CCM+’s Design Manager to run over 100 parametric CFD simulations, analyzing how nose and flap rotation angles affect thrust performance.

The study revealed that the optimized wingsail configuration achieved:

- Up to 37% higher thrust than a standard NACA0012 foil

- Stable performance across various wind directions

- Validated results under realistic ship-scale 3D conditions

Simulations were based on a 30-ton class demonstration vessel, targeting a chord length of 4 meters and a span of 10 meters. Both 2D and 3D RANS-based analyses were conducted using the SST k-ω turbulence model.

The use of STAR-CCM+ and its Design Manager allowed the team to explore a wide range of design combinations within a reasonable timeframe, contributing to a more data-driven and scalable approach to wind-assisted propulsion development.

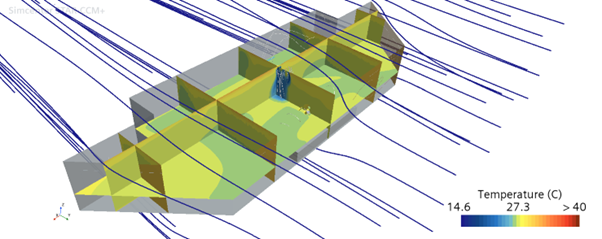

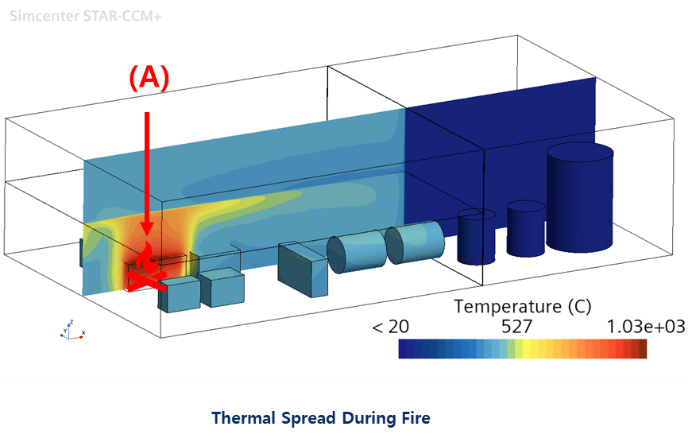

Analysis of fire risk factors for the development of MSR container ships

SSEL conducts CFD-based fire simulations using Simcenter STAR-CCM+ to evaluate the thermal impact of onboard electrical fires in MSR-powered containerships. This training offers students practical experience in simulating high-risk accident scenarios using state-of-the-art computational tools.

As part of the fire risk analysis, a scenario was defined where a fire originates from a converter in the generator compartment. Because initial fire detection and suppression were deemed to fail, the fire growth was classified as ultra-fast and students performed thermal simulations using the CFD solver of STAR-CCM+.

The simulation included:

- Realistic physical models (ideal gas law, segregated flow, realizable k-ε turbulence model, radiation model)

- Detailed ship CAD geometry

- Heat release model 𝑄=𝛼𝑡2, with ultra-fast growth rate 𝛼 = 0.1875

- 1-hour simulation (3600 seconds) with over 550,000 polyhedral meshes

Key findings:

- Fire source temperature exceeded 1,030°C

- Shield structures (lead and carbon steel) showed heat transfer but no structural failure

- Final temperatures: ~157°C (Pb), ~166°C (carbon steel)

This case demonstrates how students apply CFD tools to analyze fire progression, evaluate thermal risks and propose design improvements for nuclear-powered marine systems.

The students of Hongik University’s Department of Naval Architecture and Ocean Engineering can attest to the fact that Siemens’ support provides them with a quality education and an educational environment where they can develop and succeed holistically.

With Siemens software, Hongik University’s Department of Naval Architecture and Ocean Engineering will continue to provide innovative education and research for the development of future marine technologies and to foster young talents who will lead the future of the marine industry.

Are you an engineering educator interested in enriching your curricula with Siemens software? You can gain access to industry-grade software for your classroom by filling out our grant application form.