Supporting global champions of vocational education

During the WorldSkills competition, Siemens Digital Industries Software supported participants from all over the world in the additive manufacturing competition with the Siemens NX 3D software portfolio. Featuring a comprehensive set of proven design tools for additively manufactured parts, this portfolio helped contestants excel in their pursuit of future careers.

During the 2024 WorldSkills Competition in Lyon, France, about 1,400 young people from nearly 70 countries and regions competed for gold, silver and bronze medals in 59 skills, including additive manufacturing. Photo: Pierre-Aymeric Dillies

From 10 to 15 September 2024, the city of Lyon, France, welcomed the 47th WorldSkills Competition with young competitors from all over the world. WorldSkills International, a charity formerly known as the International Vocational Training Organization (IVTO), operates in 85 countries and regions. Founded in the 1940s with the goal of creating new employment opportunities for young people in some of the economies that were devastated by the Second World War, it describes itself as a global hub for skills.

The WorldSkills competitions aim at demonstrating the advantages of learning a vocational skill and encouraging ‘parity of esteem’ between vocational and academic qualifications. In addition to showcasing the extraordinary talents of their competitors, they underscore the critical need to break biases in technical and vocational education and training (TVET) and to create equitable access to skills for all. Moreover, the competitions highlight excellence and show how these skills can lead to a fulfilling career path.

“WorldSkills is more than just a competition—it brings together the best young professionals in their fields, both nationally and internationally,” says Raphaël Criado, silver medalist in the 2024 WorldSkills additive manufacturing competition. “Being part of such an environment of excellence inspired me to give my absolute best, with the goal of reaching those levels and aiming for the highest medal.”

Skills vital to shape the future

At the WorldSkills Lyon 2024, about 1,400 young people from nearly 70 countries and regions competed for gold, silver and bronze medals in 59 skills, from technology and construction to creative arts and service industries. In line with the WorldSkill organization’s claim “To raise the profile and recognition of skilled people, and show how important skills are in achieving economic growth and personal success,“ these included comparatively recent, future-oriented additions such as additive manufacturing in the Manufacturing and Engineering category.

More commonly known as 3D printing, additive manufacturing is one of the newest and fastest-growing branches of engineering. While traditional manufacturing methods such as milling and turning cut away material to create the desired end product, additive manufacturing creates objects such as design prototypes from three-dimensional models by building up layers of material.

A transformative production method

AM technicians require a wide range of knowledge, skil, and generic attributes, including a thorough understanding of the equipment for 3D printing and scanning, and the characteristics of the materials used, along with applied mathematics, geometry and Computer Aided Design and Engineering (CAD and CAE).

While typically complementing rather than substituting milling and turning, additive manufacturing can be a more agile way to create strong and complex objects, such as prototypes, for industry and designers with less waste. However, using this technology requires a new approach to design and manufacturing. This includes a thorough understanding of the equipment for 3D printing and scanning, and the characteristics of the materials used, along with applied mathematics, geometry and Computer Aided Design and Engineering (CAD and CAE).

AM technicians require a wide range of knowledge, skills and generic attributes. As the competition emphasizes vocational rather than academic education, it does not distinguish between theoretical and practical tests. Considering skills are a key factor in securing future workforce qualification, it pursues a holistic approach. Candidates in the additive manufacturing category can score points in fields ranging from work organization and management, communication and interpersonal skills to 3D digitalization, component or structural optimization and transfer to CAD and on to optimization, preparation and forming, finalizing and work piece delivery.

Qualified for a future workforce

Five of the 2024 WorldSkills competitors in additive manufacturing achieved medals. Gold went to Doin Yun from South Korea, while Raphaël Criado from France and China’s Xiaojiao Luo each came away with a silver medal. In addition, Prem Vasanth Kumar from India and Matheus Palha from Brazil received medallions for excellence.

“What motivated me to join the WorldSkills adventure in additive manufacturing was, above all, my passion for my field,” says Raphaël Criado. “It’s been five years since I discovered 3D design and additive manufacturing, and the possibilities feel limitless. This industry fascinates me and pushes me to challenge myself constantly.”

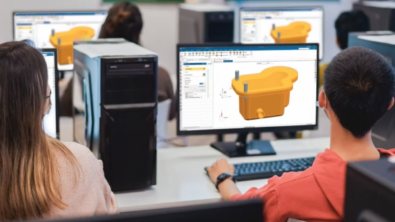

Participants in the WorldSkills 2024 additive manufacturing contest used NX software from Siemens, including the software’s smart mechanisms for topology optimization to meet strength requirements while minimizing material usage and weight.

Covering all aspects of the craft

The role of additive manufacturing technicians requires an understanding of the properties and characteristics of materials, of applied mathematics, and geometry in particular. Concerning 3D design methods, it covers 3D scanning, metrology, scan-to-CAD redesigning, CAE, build process analysis and post-processing.

“At the global level, I got the chance to apply every aspect of my craft, from 3D design and printing for technologies like FFF, DLP and resin, to 3D scanning, reverse engineering and material optimization using metrology tools like calipers,” Raphaël Criado recalls. “The challenges covered diverse, technical subjects, such as designing a construction helmet, crafting turbine components and optimizing structural frames.”

Using cutting edge additive manufacturing support software

During the WorldSkills additive manufacturing competition, participants used Siemens Digital Industries Software solutions, including NX™ out of the Siemens Xcelerator business platform of software, hardware and services. “NX software is a comprehensive portfolio of 3D software for computer-aided design, manufacturing and engineering. It features a comprehensive set of proven design tools for additively manufactured parts,” says Emilien Goetz, presales at Siemens, who was on the Siemens team supporting WorldSkills contestants using this software most of them are not familiar with.

These include tools enabling users to work with non-uniform rational basis spline (NURBS), facet/mesh, and even sub-division bodies interchangeably and together in the same part. They also support automated lattice structure creation and include smart mechanisms for topology optimization to meet strength requirements while minimizing material usage and weight. NX also includes a series of integrated solutions for validating designs against various process requirements.

“NX software is a comprehensive portfolio of 3D software for computer-aided design, manufacturing and engineering. It features a comprehensive set of proven design tools for additively manufactured parts,” says Emilien Goetz, presales at Siemens, who was on the Siemens team supporting WorldSkills contestants using this software that most of them are not familiar with.

“During the competition, I explored the full potential of additive manufacturing,” says Raphaël Criado, silver medalist in the 2024 WorldSkills additive manufacturing competition. “Using Siemens NX to prepare 3D metal laser prints was a standout experience; the software was intuitive and comprehensive, perfect for projects of this scale.”

“Siemens has been a Global Industry Partner of WorldSkills International since October 2010”, says Jonathan Frechard, Portfolio Development at Siemens. “In skills like automation and mechatronic, Siemens has been providing both hardware and software and acts as a main sponsor.” Furthermore, NX additive manufacturing software features are embedded in the leading combined machine tools from DMG for both subtractive and additive manufacturing.

Out to shape the world

“You are the changemakers. You are the people who are now going out into the world, to shape it and to find new paths to address the challenges we face,” said Chris Humphries, President of WorldSkills, to the gathered champions during the closing ceremony of WorldSkills Lyon 2024. “We need your creativity, your bold ambition and your exceptional skills. Go forward knowing that we believe in you and we all want you to thrive.” That said, he handed over the flag to representatives from Shanghai, the host city for the next WorldSkills competition in 2026.

“WorldSkills also offered me valuable exposure on social media, especially LinkedIn, which has opened many doors,” says Raphaël Criado, who is now employed by a French defense and aerospace corporation, focusing there on tooling design and additive manufacturing. “Participating in this competition was a true springboard, and I’m proud to now serve as an ambassador to inspire young and future competitors.”

“We are proud to be able to help young people get ready for the future challenges of engineering and manufacturing with our software and support,” says Emilien Goetz.

“Our ambition really goes far beyond this,” adds Jonathan Frechard: “[With the] in-depth familiarity with cutting-edge software and the improved, highly efficient processes this facilitates, young people like Raphaël Criado can give their future employers a competitive edge and a push towards a more sustainable future.“

If you’re a student, you can download Siemens NX and other software tools for free on our website.