Real-life educational experiences in the virtual world with Siemens’ digital twins

Incorporating practical, real-world experiences in the classroom is one of the most challenging yet necessary initiatives for engineering educators.

A recent study from Deloitte and The Manufacturing Institute found that U.S. manufacturers alone may need 3.8 million new employees by 2033. The study also found that of these 3.8 million open positions, 1.9 million will require specialized skills and are likely to remain unfilled without significant changes in how manufacturers address the skills gap.

These statistics emphasize the growing requirement for educational institutions to better equip students with the practical skills needed to excel on the job. Meanwhile, students are under increasing pressure to seek out industry-relevant learning experiences to increase their workforce preparedness.

However, incorporating these real-world learning experiences in traditional engineering programs is easier said than done. One common challenge is a lack of physical machines for students to learn from and experiment with.

Leveraging Siemens’ digital twins to incorporate real-world experiences

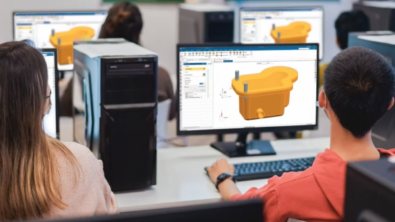

In traditional classrooms, a cohort of engineering students may have access to one physical machine and programmable logic controller (PLC). In this environment, students take turns using the PLC to control the machine while other students watch.

Inevitably, time runs out and some students don’t get the opportunity to use the machine – while others don’t get as much time as they would prefer. As a result, their learning experience suffers. Even a single machine can be costly for universities, making it prohibitively expensive to buy multiple machines for classroom use.

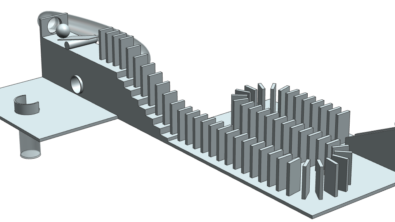

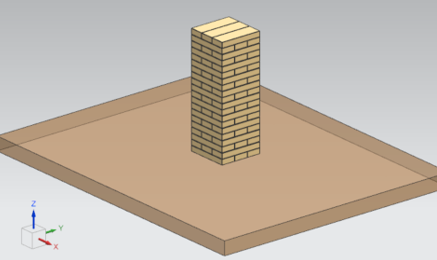

With Siemens’ digital twins for education and the Mechatronics Concept Designer in our NX portfolio, educators and students can conveniently sidestep this bottleneck with digital models of machines that behave just like real machines. To get acclimated with the tool, students are invited to experiment with simulating familiar items like a Jenga tower or pinball machine.

Digital twins that behave like real machines

What makes Siemens’ digital twins so valuable in the classroom is that they offer true-to-life physics modeling in real time. You can run real-time simulations of a machine operating and observe how the machine would behave on the shop floor. In fact, you can even use a physical controller to automate the digital twin.

For students, this means they can test their automation program on a virtual model rather than a physical model, allowing practically unlimited access to experiment and retest as they reconfigure their program. If the student has not correctly automated the machine, they will be able to see that it is not operating correctly either, just as if it were a real machine.

Best of all, every student in the classroom can use these digital twins simultaneously or asynchronously for an improved learning experience.

Digital twins are just one resource of many offered by Siemens for educators and students

In addition to digital twins for education, Siemens offers a variety of resources to help educators offer practical experiences and inspire the next generation of engineers. This includes Siemens’ award-winning NX Software with a full industrial CAD, CAM and CAE package, as well as Xcelerator Academy, where students can learn every software platform with on-demand training.

If your university would like to join our academic partner program, learn more here.

If you’re a student and would like to try the Mechatronics Concept Designer, you can download the student version of NX here along with some sample files to use here.