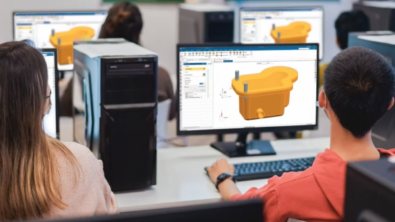

Each year, PACE (Partners for the Advancement of Collaborative Education) faculty initiate course competitions in more than 20 computer aided design, engineering graphics, computer aided engineering, and computer integrated manufacturing undergraduate courses at all levels. The PACE course competition can be readily integrated into an existing CAD/CAM/CAE engineering or design course that involves a student project using PACE software tools, no matter how elementary.

Over fifteen hundred students at more than 20 PACE Institutions interact with industry experts and receive feedback on their projects through PACE course competitions annually. Company

representatives witness first-hand the capabilities of students, potentially resulting in internship or employment opportunities. Company participants join the students either on campus, or

virtually via teleconference.

This PACE competition held April 23, 2015 fit well within the requirements of the Computer Aided Manufacturing class, which is a technical elective offered at Michigan Tech for Juniors or Senior MET majors with a concentration in the Computer Aided Engineering area. The course is designed to apply techniques used in parametric modeling (CAD) and convert this information to all phases of production planning, machining, scheduling and quality control utilizing the Siemens NX CAM package. The emphasis for the PACE competition was on the toolpath generation and verification aspect of the CAM software. Students were given the challenge to produce a working finished product and set of shop documents for a mechanism using both CNC lathe and milling machines. Students had access to the Michigan Tech School of Technology machine shop Romi M16 Lathe with a Centroid control, Haas VF3 Vertical Axis Milling center and Haas control, and an Acer Mill with Acu-rite control.

The first place awards were provided by Siemens and awards for second through fifth place with certificates were provided by General Motors for the event. The judging was provided by volunteer manufacturing engineering professionals from General Motors, Siemens, and Great Lakes Sound and Vibration (Houghton, Michigan). The judges rated projects on criteria of: design being innovative and detail oriented; manufacturing methods used; generation of efficient and accurate toolpath and post processed NC code; design incorporating ease of manufacture, and the presentation quality. Eleven students competed in the contest each presenting their designs and finished manufactured parts for the judges in a short ten minute time slot.

The first place awards were provided by Siemens and awards for second through fifth place with certificates were provided by General Motors for the event. The judging was provided by volunteer manufacturing engineering professionals from General Motors, Siemens, and Great Lakes Sound and Vibration (Houghton, Michigan). The judges rated projects on criteria of: design being innovative and detail oriented; manufacturing methods used; generation of efficient and accurate toolpath and post processed NC code; design incorporating ease of manufacture, and the presentation quality. Eleven students competed in the contest each presenting their designs and finished manufactured parts for the judges in a short ten minute time slot.

First place in the competition was awarded to Matthew Brettschneider, senior MET student, who explained his project to optimize the current machining process for the Michigan Tech Blizzard Baja CVT Secondary Dynamic Sheave. The process starts with a pre-machined cylindrical blank held in the HAAS VF3 with a four jaw chuck to mill the back webbing. Next, it is placed in a custom designed soft jaw fixture mounted in the ROMI M16 lathe to face the belt surface and finish bore the hole. To finish the part, it is transferred back to the VF3 using the same four jaw chuck to mill the front face and drill three holes. This one part project incorporated both mill and lathe operations in one part verses having multiple components to machine like the other student projects.

First place in the competition was awarded to Matthew Brettschneider, senior MET student, who explained his project to optimize the current machining process for the Michigan Tech Blizzard Baja CVT Secondary Dynamic Sheave. The process starts with a pre-machined cylindrical blank held in the HAAS VF3 with a four jaw chuck to mill the back webbing. Next, it is placed in a custom designed soft jaw fixture mounted in the ROMI M16 lathe to face the belt surface and finish bore the hole. To finish the part, it is transferred back to the VF3 using the same four jaw chuck to mill the front face and drill three holes. This one part project incorporated both mill and lathe operations in one part verses having multiple components to machine like the other student projects.

The other award winning projects also had innovative designs and well machined products, but were not as well illustrative of the process of utilizing the CAM generated programs as compared to manual operations and the associated cost savings. Rounding out the rest of the awards were: 2nd place, Double Pizza Cutter by Alex Tomasoski; 3rd place, Gyroscope by Charles Hayes; 4th place, Miniature Cannon by Macrae Parks; and 5th place, Snowmobile Cargo Rack by Bradley Blunden. We would like to acknowledge the School of Technology Machine Shop staff for their knowledge, assistance and patience as lab teaching assistants during the course. Check out PACE site

The other award winning projects also had innovative designs and well machined products, but were not as well illustrative of the process of utilizing the CAM generated programs as compared to manual operations and the associated cost savings. Rounding out the rest of the awards were: 2nd place, Double Pizza Cutter by Alex Tomasoski; 3rd place, Gyroscope by Charles Hayes; 4th place, Miniature Cannon by Macrae Parks; and 5th place, Snowmobile Cargo Rack by Bradley Blunden. We would like to acknowledge the School of Technology Machine Shop staff for their knowledge, assistance and patience as lab teaching assistants during the course. Check out PACE site