Building the next generation of intelligent manufacturing talent at Sichuan Polytechnic University

According to the World Manufacturing Foundation, 74 percent of manufacturing companies globally report an acute lack of high-skilled workers, and 94 percent expect to hire or repurpose talent as they adopt Industry 5.0 technologies. By 2030, more than half of the advanced manufacturing workforce will require upskilling to keep pace with digital transformation.

To address this growing skills gap, Sichuan Polytechnic University has recently explored novel vocational education models in collaboration with local industrial organizations.

Educators, apply for an academic partner grant today to gain access to Siemens’ software for your classroom.

Located in Deyang City, Sichuan Province, Sichuan Polytechnic University is the first public vocational undergraduate university in Sichuan Province with over 16,000 students and 1,400 faculty members. Boasting 49 undergraduate and specialized programs, the university combines strong academic foundations with deep industry partnerships.

In 2018 and 2021 respectively, Sichuan Polytechnic University (formerly known as Sichuan Engineering Technical College) launched two exciting projects with Siemens to address the intelligent manufacturing skills gap. In 2018, they established the Intelligent Manufacturing Innovation Center organization, an independent legal entity dedicated to bridging campus scientific research and innovation service with real projects involving industrial organizations. Furthermore, in 2021, they set up an Intelligent Manufacturing Industry College to introduce Siemens’ software courses.

Since then, the university has educated hundreds of students in leading intelligent manufacturing technologies and practices.

Building a major to meet the needs of intelligent manufacturing today

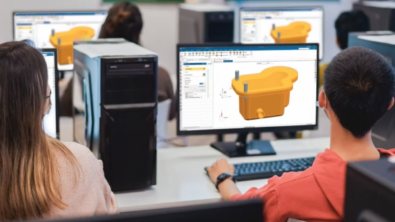

This cutting-edge major immerses students in major stages of intelligent manufacturing, such as parts 3D modeling, mechatronics design and simulation, robot workstation design, simulation and optimization, production line modeling (via reverse engineering and the digital twin), plant planning and material flow simulation and product lifecycle management (PLM).

Siemens’ software, such as Designcenter NX, NX MCD, Teamcenter, Process Design & Simulate and Plant Simulation, are embedded into lectures, practical training and capstone assignments. Project-based teaching means that each semester, student teams tackle authentic use cases drawn from enterprise partners, ensuring graduates step into roles designing mechanical equipment, planning digital production or delivering PLM services with confidence.

The teaching team is equally impressive. Faculty include China’s first nationally outstanding teachers, National Technical Expert award winners and Light of the West talents from the Chinese Academy of Sciences. Most recently, Professor Zhang Bin led his team to first place at the 4th National Intelligent Manufacturing Application Technology Skills Competition.

Bringing industry and academia together at the Intelligent Manufacturing Innovation Center

As China’s first Siemens-powered Intelligent Manufacturing Innovation Center for integrating industry and education, the space hosts live industrial projects that students complete as paid interns.

With Siemens’ industry-leading software and intelligent manufacturing hardware, the Intelligent Manufacturing Innovation Center ensures academic labs mirror tomorrow’s smart factories. Faculty continually update practical training course materials based on real industrial project outcomes, keeping curricula aligned with digital transformation.

Sichuan Polytechnic students have earned national acclaim in competitions and more

Since its debut, students from the Industry College and Innovation Center have won national recognition for their work.

In 2022, Sichuan Polytechnic students won the first prize in Industrial Design Technology at the National Vocational College Skills Competition, followed by back-to-back first prizes in the Intelligent Manufacturing Competition of the 2023 and 2024 China University Students’ Mechanical Engineering Innovation and Creativity Competition. Additionally, a Sichuan Polytechnic student team won first prize in the 2024 National College Students’ Mechanical Innovation Design Competition. Lastly, employers have consistently praised graduates for their ability to add value early in their careers due to their familiarity with Siemens’ software and hands-on project experience.

Learn more about how Siemens supports engineering educators globally with software access, credentials to enrich engineering curricula and more.