How grit and teamwork drive Michigan Baja’s off-road excellence

For many engineering students, it’s difficult to get a true grasp on what it’s like to face unbounded, dynamic challenges until they enter industry.

Whether it’s working within evolving automotive regulations or designing components to withstand the extreme conditions of outer space, the demands of industry require not just technical skills but grit, flexibility and the ability to collaborate within (and across) teams.

But for the dedicated students competing in Baja SAE, navigating these challenges is just a day-in-the-life.

Students can now register for the FREE Expedite – Skills for Competitions microcredential from Siemens. Earn key skills needed to enter your first competition with confidence, learn how to translate your experiences into compelling resume highlights and demonstrate your readiness to enter the workforce.

Baja SAE, a Collegiate Design Series competition sanctioned by the Society of Automotive Engineers International (SAE International), challenges students to design, build and race small off-road cars through rugged terrain and unforgiving conditions.

Teams compete in a variety of events including an endurance race, maneuverability course, sled pull, hill climb and more.

This intense, hands-on battle against the elements and engineering constraints prepares students for the rigor required in professional engineering in a way few other experiences can.

Siemens’ Global Academic and Future Workforce Program recently had the opportunity to speak with Pierce Bednas, a mechanical engineering student and team captain of the University of Michigan’s Baja SAE team.

The University of Michigan Baja SAE placed second overall in the Mike Schmidt Memorial Iron Team Award (the national title for Baja SAE) in 2025 and has won nine out of the last 12 awards. In a recent interview, Pierce shared key insights on the value of this competition for engineers preparing for their careers and the secrets behind Michigan Baja’s success.

A high-pressure, high-reward environment for developing key engineering skills

Pierce’s journey with the team is a testament to the growth and learning fostered by such programs.

Like many of his teammates, Pierce joined as a freshman three years ago, eager to get involved in a hands-on engineering team. “I loved it pretty much from the instant I joined,” Pierce recalled.

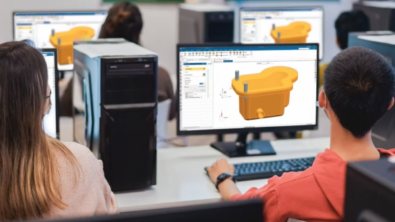

His dedication saw him quickly take on more responsibility, becoming the chassis lead in his sophomore year, where he deeply utilized Siemens NX for design. By his junior year, he was the rear gearbox lead, diving even further into advanced CAD tools and complex technical designs. This progression culminated in him being voted team captain at the end of his junior year.

This individual growth is mirrored in the team’s overall expansion. “Since I joined the team, we went from a team of just around 20 members to well over 60, which has been great to see,” he shared, highlighting the increasing interest and involvement from students who are eager to develop into skilled engineers.

Continuing Michigan Baja’s legacy of excellence

This season has been no exception to their high-performance standard. During Baja SAE’s first competition in 2025 in Arizona, the team secured an impressive fifth-place overall finish among 80 competing teams, despite a few minor component failures.

They then went on to the Maryland competition, where they placed second overall and clinched first place in the grueling endurance race.

This endurance race win was particularly dramatic. “We placed first and beat Cornell, the second-place team in the endurance race by just under a lap,” Pierce recounted.

The victory was hard-won:

“On the last couple of laps of the endurance race, we had an issue with our transmission where a component failed and basically locked our transmission in place. So, we weren’t able to drive. And luckily we were able to get the car towed into our pit area, fix the issue and get back out on the track with just enough time to finish the race and win.”

This exciting comeback illustrates the team’s resilience and problem-solving prowess under pressure.

Learning from challenges: The tech inspection gauntlet

For as thrilling as victory can be, the team’s true growth often comes from confronting and overcoming significant challenges. Pierce shared a high-stress incident from the tech inspection at his first event as team lead:

“Going through the tech inspection at competition, which is a very stressful process… we obviously had read the rules very thoroughly and thought we knew everything. And we went through tech inspection and found out that our seat mounting wasn’t up to the standards on what they were expecting…and we found that out about 30 minutes before the tech inspection closed.”

What followed was a frantic but ultimately successful team effort. “We were rushing as a team to find a solution and ultimately found a solution in those 30 minutes that the tech inspectors would be happy with. And then spent the rest of the night up until probably around 1:00 a.m. trying to weld the new seat structure for our vehicle. And it’s always great when we have situations like that; seeing the whole team come together to find a solution.”

During these high-pressure situations, the team has found a lot of value in Siemens software, too.

“With more than 40 engineering students working together, Teamcenter has provided a structured environment for part libraries and collaborative design,” said Pierce. “This has helped ensure that every team member is working with the most up-to-date models, which helps improve work channels between subsystems, since design changes would automatically update within the full car model.”

In addition to Teamcenter, NX has provided a flexible, powerful design solution for the team.

“NX is the default CAD tool for the team…using NX through the Baja team has led it to be my favorite CAD software. The ease of being able to import different components into an assembly and easily being able to reference those components has been great for going through the design process and being able to quickly design prototypes.”

The University of Michigan Baja SAE team exemplifies how hands-on engineering projects, coupled with powerful tools like Siemens NX and Teamcenter, prepare students not just for graduation, but for thriving in the complex, collaborative and challenging world of professional engineering.

Register for Expedite – Skills for Competitions today to prepare for your first engineering competition.