Podcast transcript: From classroom to racetrack: The National University of Singapore’s Formula SAE journey

What if your classroom project involved designing a Formula 1-style car to compete in an international race?

In this episode of Innovation in the Classroom, Shannon O’Donnell dives into the thrilling world of Formula SAE, where innovative engineering students push the boundaries of design, performance and teamwork. Join Shannon for a chat with Hong Wee Lim, the Project Supervisor for the National University of Singapore’s (NUS) Formula SAE team.

Every year, his team designs, builds and races Formula 1-style cars, preparing to compete on the global stage at Michigan’s Formula SAE (FSAE) student engineering competition. But behind the thrill of competition lies a relentless cycle of sleepless nights, technical failures and fierce deadlines as these students face the daunting challenge of turning their designs into race-ready machines.

Hong Wee offers a unique glimpse into how the NUS team transforms classroom theories into high-speed reality. From his journey as a mechanical engineer to managing a group of passionate students, Hong Wee Lim shares the highs and lows of leading a project that combines intense technical learning, innovative problem-solving and the adrenaline rush of motorsports.

In this episode, you will learn:

- What is Formula SAE, and how do students compete internationally (10:00)

- How do students benefit after they graduate from participating in FSAE? (14:45)

- The roles of AI, machine learning and additive manufacturing in FSAE (21:00)

- How students enhance their people and leadership skills (22:44)

- How students adopt an innovative mindset (25:15)

- The application of Siemens software in FSAE (38:10)

Connect with

Shannon O’Donnell

Hong Wee Lim

As mentioned in the podcast

NUS Engineering Design and Innovation Centre

Podcast transcript:

[00:02] Shannon O’Donnell: Welcome to Innovation in the Classroom by the Siemens Empowers Education Team. I’m Shannon O’Donnell. Today, we’re speaking to the project supervisor for the National University of Singapore’s Formula SAE team, Hong Wee Lim. Every year, the team designs, builds, tests and races Formula One-style vehicles to prepare to compete at Michigan’s Formula Student competition. In this episode, Hong Wee breaks down what the National University of Singapore’s Formula SAE team does, talks about its origins, and how he became a part of it. He describes what he believes is the key to success when racing these vehicles and what kind of support the team receives from external parties. We also learn about Hong Wee’s educational background, his professional goals and so much more. Join us as we dive into this conversation.

[01:08] Shannon O’Donnell: I am so excited to be talking with a global force in Formula Student competitions. Hong Wee Lim, it’s nice to have you on this episode of Innovation in the Classroom, which we’re going to take out onto the course a little bit today. But as we’re coming into this conversation, if you wouldn’t mind telling us a little bit about yourself and what your expertise is, in addition to the position that you hold at your university.

[01:38] Hong Wee Lim: Hi Shannon, thanks for having me here. I’m Hong Wee, and I am the Project Supervisor for the Formula SAE project at the National University of Singapore. My expertise is in mechanical engineering. I manage a team of students who build open-wheel, Formula-style race cars for competition in America every year.

[02:02] Shannon O’Donnell: So, when you were in school, tell us a little bit about what you studied.

[02:06] Hong Wee Lim: We studied the basic theories in terms of engineering, but to a certain extent, sometimes it was too much theory. When there’s no link to the practical world, students don’t really understand. So, joining this project actually helped us understand the engineering theories a lot better. From there, we use software tools to optimize the design, to do better design and understand engineering first principles in order to build a proper and better car.

[02:35] Shannon O’Donnell: So, when you were in school, were you a mechanical engineer, or an automotive engineer? Or did you study something different?

[02:42] Hong Wee Lim: I’m a mechanical engineer. At our university, there’s only a mechanical engineering degree—there’s no automotive degree.

[02:49] Shannon O’Donnell: Tell us a little bit about what motivated you to go into engineering.

[02:55] Hong Wee Lim: I would say that I’ve been interested in how things work since I was young. Sometimes, with the toys we had, I always liked to dismantle them and, sometimes, modify them—like what typical young boys enjoy doing. Eventually, when I started studying, I became interested in physics. From there, engineering attracted me. At this point, engineering is really the foundation of everything in our daily life—even finance structures are built on engineering. Without technology, there’s no finance, to a certain extent. At the end of the day, I’m also very interested in engineering because engineers are the ones who solve practical problems. Scientists discover new things, but engineers make those discoveries work in the practical world. That’s something very intriguing for me.

[03:44] Shannon O’Donnell: So, if you were to start a business today in any form of engineering, what would you want to start an engineering company in?

[03:52] Hong Wee Lim: Because engineering is such a diverse field, for me, it would be something like a consultancy, where I could help in different fields of engineering. The most important thing is designing things the right way. Sometimes, when you are designing a complicated system, it’s actually very easy to design something that isn’t optimized for manufacturability or cost—or even performance, which is the most important aspect. So, being an engineering consultancy, I would be able to help different companies do things right.

[04:26] Shannon O’Donnell: That’s fantastic. If you take that content and mindset of consultancy, and if you had the opportunity to focus on realizing, designing, or optimizing, which one would you want to focus on the most?

[04:41] Hong Wee Lim: I would say that all of them work together. It’s still both. At the end of the day, for companies, it’s always about the cost. If they’re really looking at reducing cost, it’s all about manufacturing and optimizing won’t really be a big issue. It’s all about balance. That’s something very important because, when we’re working on things, balance is important. It’s not just about doing something that someone thinks will be good, but rather about what the company or the client actually wants. That’s the most important thing.

[05:14] Shannon O’Donnell: The goal of this podcast is really to talk with people who are involved with students interested in competition, or to speak with students who might be interested in joining a competition team—or maybe even helping support faculty members that students consult with as they are going and creating their competition. As we’re getting started, we also have pieces of the audience who might not know what Formula Student is. Could you give us a little introduction to what Formula SAE is?

[05:50] Hong Wee Lim: Formula SAE is actually an event organized by the Society of Automotive Engineers (SAE), and it’s an international competition held in many parts of the world—mostly in countries that manufacture vehicles. That’s where companies recruit a lot of students from this competition. Different universities participate, and it involves a student team designing and building an open-wheel, Formula-style car. The cars are not too big or too fast—just in case there are accidents. The teams aren’t racing against each other; they’re mostly racing against time on a closed circuit, so there are no hard barriers for the cars to crash into. This competition looks at the design process of the team, as well as the performance of the car. Students aren’t just designing and building the car—they’re also optimizing their design, tuning the car, testing it, collecting data and validating their design. They have to present all of this to the judges during the competition, and the judges are mostly from the automotive and racing industries, so they really know their stuff. We always tell our students, “If you don’t know, say you don’t know. Don’t try to bluff them.” The judges are experts in the field. In the competition itself, there are three static events and four dynamic events. The static events will be the presentation events, where they have to present their engineering design. They’ll explain what their objectives were for the car that year and what they did to achieve those objectives. At the end of the day, whether their testing met their goals and if they validated testing data.

[07:30] Hong Wee Lim: Then, there’s a business presentation, where they are given a real-world business scenario, and they have to present. For example, in the current economic situation, how would they ramp up production? What should they do as a business? Finally, there’s a cost presentation, where they present the cost of the car, which is something a lot of the companies are doing. They must account for every small part—how it’s manufactured, how much it costs—and make sure everything is properly documented. Then, on top of that, there are the four dynamic events. First is the straight-line acceleration. Then, the figure-eight skidpad, which tests both the straight-line and cornering capabilities of the car. Then, there’s the dynamic track, the autocross —a one-lap time attack. Finally, there’s a 22-kilometer endurance race with a driver change in between. In order to participate in these dynamic events, the car must pass a technical inspection before it is allowed to run. This is one of the biggest challenges because there are a lot of rules to adhere to. We have a pretty big rule book, and sometimes we might miss the rules. Sometimes it’s based on the interpretation because they are not able to run everything. When we try to innovate, sometimes we break the rules, so the judges have to decide on the spot if it’s safe or not. If we fail to meet the rules, we have to modify the car on the spot to make sure it passes. So, this is something that is very challenging.

[09:04] Shannon O’Donnell: So, for a student who’s new to a competition, what’s the typical role that a first-year engineering student would have on the team? There are a lot of technical aspects that they’re responsible for, as well as the business side. So, when someone is a first-year engineering student, what is it that they typically do?

[09:25] Hong Wee Lim: I think it depends on the university because different universities run their teams differently. But at the National University of Singapore, what we do is take in students from their second year. From the second year, they actually become apprentices. It always starts with the old and traditional way of engineering: learning the basics and doing very mundane tasks. That’s where they learn the hard skills, because a lot of hands-on skills are required for them to really design later on in their careers. We give them a lot of lessons, and it can be difficult to absorb because they’re still pretty new, and we’re directly teaching them automotive engineering lessons. They also interact with their seniors a lot. Not only do we have lessons, but we also have interaction with seniors and tasks for them to complete, so they can pick up the ropes quickly. By their third year, they’ll be part of the main team. They learn a lot more during their third year from their seniors to designing the car. Learning small tasks versus designing a full system is very different. It’s difficult to give them something big to design when they’re in the apprentice stage, so we slowly build up their foundation before moving them into the next stage.

[10:50] Shannon O’Donnell: So, at the National University of Singapore, approximately how many or what percentage of engineering majors are competing in Formula Student?

[11:01] Hong Wee Lim: I would say it’s a pretty small group. When we put up recruitment notices, not a lot of people want to join. We’re competing with a lot of other projects and competitions in the university as well. Right now, the trend is AI, so building a car isn’t seen as something new. But there are definitely people who are very passionate about building cars—a lot of them have dreamed since they were young. I’d say we start with around 50 people at the beginning, but our engineering cohort is much larger, in the thousands. To a certain sense, we are not able to manage too many people as well. We only have a handful of staff. The senior students are also busy building the car, so they don’t have much time to manage the students. Eventually, they will drop out. Evern though, we are taking around 50 to 60 people, and we’re left with about ten or so in the main team. In our third and fourth-year main team, we usually have around 20 people each year.

[12:09] Shannon O’Donnell: For those students that are competing, do you find that they’re energized to pass difficult classes because they enjoy the competition so much? And do you find that job offers are significant because they’ve had this experience with Formula SAE?

[12:27] Hong Wee Lim: I would say yes. In fact, some of our sponsors actually sponsor us every year just to recruit our students to work with them. I will say that in Singapore, the engineering scene is not that strong—it’s not super highly sought after—but companies that know us, like those in the aerospace and defense industries, always want to take our students. In fact, we have students who are now working in Formula One teams. A few of them went overseas for postgraduate studies, and we also have several students working in the electric vehicle (EV) industry in the US and China. What we do is train the students to have the necessary skills before they even go to the competition, and that’s part of what the competition is about. The purpose of Formula SAE is also to prepare students to be hirable with the knowledge and skills they need before entering the industry.

[13:23] Shannon O’Donnell: So, real-world experience is coming through even as undergraduates. There are so many people, I think, who work in silos, but Formula SAE seems to provide a bird’s-eye view of everything in a more model-based approach.

[13:43] Hong Wee Lim: Not just about engineering, they are actually good at managing people because, in the team, they have to manage so many individuals. When the juniors enter, they have very few skills, and the seniors have to help them develop those skills, motivate them, and keep them from getting demoralized. In our project, there are always things that tend to fail, but it’s all about learning through failure. They just have to stay motivated. And it’s not just that; they’re balancing their studies at the same time. They have to build a car and they have to study. There are so many things going on. I would say most of them don’t really have their own life to a certain sense. The whole two years are spent on SAE.

[14:31] Shannon O’Donnell: You mentioned earlier that some of your previous alumni are working in China and the Americas. Could you tell us a little bit about what competitions your team competes in?

[14:45] Hong Wee Lim: We go to the Michigan competition every year because it’s just nice—it’s our summer break and people are around. So that’s why we actually go to this competition. It is actually very far. We have to travel, we have to fly 24 hours to reach there. When we go there, we actually still prep a lot. It’s not just that we go there for the competition. We have to freight our car over, and when we freight our car over, we have to strip down a lot of things. And after that, when we are there, we have to make sure that everything is assembled back and is working properly. So, that’s why we have to spend almost one to two weeks prior to the competition to get there and start doing test runs based on the weather, on the floor, on the traction and the drivers will have to do more training over there. Our typical timeline: the competition is in June. We actually start freighting our car at the end of May—actually, one week before May—because we are flying at the end of May, and we reach there two weeks earlier. So, that’s why we have to freight our car. We actually start somewhere in the middle of May, packing everything. We have to pack almost our whole workshop over because we need the tools, we need the spares. Sometimes, it might be difficult to buy in America. We’re not sure, so that’s why we make sure that we bring everything over, especially the manufactured stuff, because we will not have time to manufacture things in America itself. So, we actually pack a lot of things. We have three crates now—one for the car and two for accessories. Some of them weigh one ton each for the crates themselves. There’s just so much stuff we need to bring over, and we have to make sure that they don’t get damaged after they reach there. So, we have to pack everything nicely.

[16:25] Hong Wee Lim: Once we are there in June, we will actually test-run for two weeks before the competition, and after the competition, we have to pack again. We pack everything in two weeks in Singapore, but we pack everything back in one day when we’re in America because we have to fly back fast. So, that’s the thing. And to a certain extent, after that packing and going back, that is the only one-week break we have for the whole year, until July. When July starts, the new design starts. Actually, the junior team, who are back in Singapore, are already starting to design from May after their exams. So, our semester is actually—our summer break is from May to August, and our winter break is from November to December or January. So, in July, we start the design. We design for around three months until September, when we lock down our design, because we try to practice what the industry does. When there’s a deadline to meet, we actually have to freeze our design by a certain time. We can’t just keep dragging on, because to a certain extent, design will always improve if more time is given. From September onwards, which is their term time, they will actually be going for lessons. We will send our items out for manufacturing. They will do some of their own manufacturing during their free time. So, we will manufacture our stuff and make sure that everything comes back on time, up until, I would say, November or December, when they are on holiday again. Holiday is our favorite time because everybody can get together—there are no lessons—and that’s when they start assembling the car, up until January. From January onwards, we will start test-running the car—making sure the car is running, collecting data, doing tuning and training the drivers. We’ll be training all the way up until, I would say, May. And that’s when we actually start the cycle again: packing and going for the competition.

[18:12] Shannon O’Donnell: When you look at the overall expenses of running a team for 12 months out of the year—the travel, shipping the car—how is all of that paid for? Is it tuition dollars, or is there something else?

[18:28] Hong Wee Lim: Most of the cost is actually borne by the university, and we are glad that the university has supported us for the past 20-odd years to participate in the competition. So, it is something that’s important. We’re also finding sponsors. We have sponsors like DHL, who actually help freight the car over, which is a very big cost—especially after COVID, with all the wars—shipping is actually very expensive now. So, we are very glad that we have this big chunk of cost taken away from us. We also find additional sponsors because sponsorship is very important. That’s where our sponsorship team comes in, to help us find sponsors and alleviate the cost from the university.

[18:41] Shannon O’Donnell: Is your sponsorship group made up of students, or are those people from the university?

[19:11] Hong Wee Lim: It’s the same team that designs the car. We did try to find people from the university, but the commitment level was actually very low. That’s why we decided to contain everything within the team itself. We did try to find some amateur racers to train us, and those were more one-off situations. That’s more feasible. But when it comes to marketing teams or sponsorship teams, it’s actually quite tough to find people from outside.

[19:40] Shannon O’Donnell: So, it’s not that there are students that are marketing majors students. Are they usually engineering majors?

[19:46] Hong Wee Lim: We are trying to work something out, something that can match their curriculum, but it seems quite tough to match some of their curriculum. If we are looking for help, usually people want to know what value they will get, other than the experience. So, we try to find more value. Can it be part of their modules or part of a project where they can earn credits or something like that?

[20:09] Shannon O’Donnell: Do your engineering students receive any course credit or anything in the curriculum?

[20:17] Hong Wee Lim: They have a kind of design project in their third year, and they’re actually using our project for that, as well as for their final-year project and thesis. So, they’re doing both of these for their modular credits. There are a few smaller modules as well that they use, but not a lot.

[20:37] Shannon O’Donnell: You mentioned AI earlier. What’s the conversation around AI within Formula SAE? Are students allowed to use it, or are they discouraged from using it? Also, regarding additive manufacturing, I think both of those are areas we’re hearing a lot about from students these days.

[20:57] Hong Wee Lim: For AI itself, I think the rules don’t really stop us from using it. I would say there’s actually another competition in Formula SAE, which is the autonomous vehicle competition. I think they use AI much more than we do because, for us, we’re still mostly hard-coding the car since the driver controls it. We’re not really using AI much at this point, but we do use machine learning, which is a form of AI, to some extent. We use machine learning for lap-time simulation software. We try to mimic the car in the virtual world to see how it behaves so that we can make decisions—like how small changes affect the car’s performance—and ensure the data and the car’s behavior is the same. For additive manufacturing, we’re using a lot more of it now for components and looking for more options. It’s just that the cost can be quite high, especially for structural components made of metal, which are more expensive. So, we’re looking at how we can have a mix between traditional machining and 3D printing or 3D printing with composites. We’re using a lot of composites now, and we’re looking at how we can [22:23 inaudible] 3D printing composites in combination.

[22:27] Shannon O’Donnell: We’ve talked a lot about the curriculum and what’s included in the way that students compete, but let’s take a second to discuss leadership skills. You mentioned leadership skills a little while ago—what do you see as the qualities that make the best type of teammate and competitor in Formula SAE?

[22:45] Hong Wee Lim: In terms of a teammate and competitor in FSAE, from our years of running the project, I would say that discipline is the most important because, with discipline, you can be disciplined to be good or bad, to a certain extent. You can actually be disciplined to have good qualities. That’s why I will say that discipline is most important that makes a good teammate. With the discipline, to design a car, students will be able to finish their jobs fast, and from there, they can help their teammates, which is the most important part of our project. We can’t really divide the workload equally. We divide it by department. Some departments have slightly less stuff to do. Some have more on the design part and less on the manufacturing, while some have the other way around. So, when students finish their part, they help each other because they have a passion for engineering. That is the second part—passion—which is very important.

[23:45] Hong Wee Lim: As I mentioned earlier, we took in 50+ people, but in the end, we only keep about 10. The rest drop out because they can’t handle the workload or the apprenticeship. Or after their results come out, they feel that they didn’t do very well and they didn’t focus more on their studies. So, passion is very important. Students don’t feel fatigued or unmotivated for the long hours of work. All the failures they face, they find new ways to solve problems. This passion also gives them a competitive nature to make the car better. When they go to the competition and see other cars, they feel even more motivated to do well. They start looking at how different teams design their cars, talk to other teams and make the next car better. Finally, the last point is being like a family. The student team becomes a big family, looking out for each other and helping out when needed. In fact, they spend more time working on the car than with their actual families, to a certain extent. So, it’s very important for them to be looking out for each other and helping each other to make sure that the car can be completed within the timeline.

[25:00] Shannon O’Donnell: With everything you shared, one of the things I saw on your website is that you’re really focused on innovation. This is the Innovation in the Classroom podcast, so let me ask you this: how do you guide your students to think innovatively?

[25:17] Hong Wee Lim: In terms of innovation, it depends on whether we’re talking about very big innovations or smaller ones. We are doing very small innovations along the way rather than big ones. If you’re talking about big innovations, you’d ask things like, “Why are cars still using four wheels at this point?” You’d never really reach an end. So, we focus on small innovations, like component design and integration of parts. What I always do is check through their designs and ask them, “So what if?” The “so what if” is very important. “So what if you do it this way or that way?” I encourage them to find better ways of doing things. In terms of doing things better, if we give them an idea—we’ll give them a very vague idea—it might not necessarily work. They’ll have to take the design to redesign the thing and compare it with their original design to see whether it’s better or not. That way, they’re not just listening to what I say, like “I say, you change” kind of thing. But when I give you an idea, you have to validate whether it’s really good or not.

[26:26] Hong Wee Lim: So, there will be very small things along the way, like, “Can you save a bolt?” or “Can you remove one bolt from the components?” Ultimately, what is the aim of what we are doing? To reduce weight, to make things stronger, or something like that. There’s always a compromise. So, in terms of innovation, we also focus on compromise, which is very important because, ultimately, the car has to work no matter what. That’s where we have to balance innovation with practicality. In terms of innovation itself, they have to, from the very beginning, know the first principles of engineering. During the course of teaching, we also try to introduce them to different innovations that racing teams or the automotive industry have done. We give them examples so that they can slowly understand, “Oh, they did this, and that’s why the car became better or more competitive. Why did they do this?” Especially in Formula One, which has a lot of examples of how teams stay on the competitive edge. During education, during junior years, we infuse these innovation examples from the industry.

[27:41] Shannon O’Donnell: With everything that you’ve seen in terms of innovation, can you give us an example of some of the most unique creations that you have seen in the program that students have come up with?

[27:54] Hong Wee Lim: Something that is easier to understand is that we actually did a conversion to EV within a year. That is something that, from everybody having no experience converting to EV—because we have been teaching internal combustion engines every year—and suddenly, we decided, during COVID, to put a stop and convert to EV. We managed to get the car out and running within a year itself. So, that is something that is very unique. It shows that if we were to face changes, we are actually very fast to adapt to changes and we have the capability of redesigning things very fast, making sure that it’s safe, it’s optimized, you follow the rules and make it work. That’s the most important—make it work.

[28:38] Shannon O’Donnell: That’s really good advice, just make it work. Is there any other valuable lesson that students have learned that you weren’t expecting?

[28:46] Hong Wee Lim: Students become a better person after they are out from the project because they actually go through all the gruesome engineering work. They have very little time. Some of them even feel like retiring after they graduate. So, it is something that makes them a better person because they understand empathy, they understand what it is to help people, they know teamwork very well. And actually, they learn a lot of things through failure, hard work and being very resilient. So, I would say that it makes them a better, more complete person at the end of the day.

[29:24] Shannon O’Donnell: I know that you’re not soliciting funds from any companies or anything along those lines during this podcast, but if you had to give a pitch to somebody about why they should hire from the Formula Student teams, what would that pitch be? You just shared a lot of amazing skills, but I’d really love to hear what your pitch would be.

[29:46] Hong Wee Lim: These students who actually graduate from the program—they have more than two years of experience before they even go to work. And with that, the companies don’t really need to train them on a lot of things. And they are actually very good team players who will be able to integrate well with the company. In fact, some of our graduates who actually work in engineering companies say that it is actually less challenging compared to the competition itself, because a competition vehicle is very competitive. It is kind of a very short timeframe to create something. But companies actually need to make sure that everything works and are working with a big team. So they say that sometimes it gets boring working for the company. So yeah, I would say that it is about getting students who have a lot of experience. I have seniors who actually applied for jobs that required five years of working experience, and they got it.

[30:41] Shannon O’Donnell: Congratulations. That’s impressive for them, and for you. When you’re looking at all of this, and you look back and say, “This is the most successful thing that we’ve done as a team,” what would that be for you?

[30:57] Hong Wee Lim: I would say that, in our country, where we are not really focused on engineering, actually getting the car out every year and being able to go to the competition is a very big feat to begin with. So that’s why I would say it’s always about getting the car to the competition every year. In fact, there are some teams that don’t go to competition every year. I mean, we didn’t go during COVID, but other than that, we’ve participated every year. So, that’s a great feat, because, as you look at the cycle that I mentioned before, it just keeps rolling and rolling. To a certain extent, I would say all FSAE teams in the world face the same problem—we have half of the most experienced team members graduating every year. It’s like operating a company where half of your most experienced workers are disappearing, quitting, or resigning every year. That’s something that’s very difficult to manage for an FSAE team.

[32:04] Shannon O’Donnell: When you come to Michigan this year, what are the team’s goals?

[32:09] Hong Wee Lim: At this point, because it’s the second year that we’ve participated in the EV competition, I would say our goal at this point is still making sure that the car is reliable. Building an EV is challenging because of high voltage—it’s dangerous. So, in the competition, if there’s any small fault, the car will shut down. It becomes such that the car won’t even start. That’s a challenge we have to face. We need to make sure the car is reliable, and that no faults come from any of the systems. To a certain extent, we do things step by step. Of course, in this era, a lot of people like to move fast, but for us, the foundation is very important. If the car is not reliable, we’re not going to throw in innovative stuff or change big systems. We make sure everything is working well first. Once everything is working well, we start tuning it, making it better. And when we know there’s no other way to improve it, that’s when we start changing systems. But, at least we have the foundation going on.

[33:16] Shannon O’Donnell: Since you compete every year, and our audience might be a little competitive, what is it that you want your team to be the best at?

[33:26] Hong Wee Lim: Our university doesn’t really offer an automotive degree, so to a certain extent, we’re still lacking in some knowledge. That’s why, when we go to the competition and present, some of the judges feel that we know a lot of things, but there are also things we don’t know. So, I would say that in order for us to be competitive, we still have to back up our knowledge with the basic foundation of automotive engineering. This isn’t easy because we’re learning everything on our own at this point. We have to make sure that what we’re learning is in tune with what overseas universities are teaching, so we’ll be able to understand more. So, I would say that learning is still the most important thing.

[34:11] Shannon O’Donnell: Are you in collaboration with any American university to learn some of that, or are you working with them? Or is it really that when you come to the US, the team is just coming to compete?

[34:24] Hong Wee Lim: We’re not collaborating with any university at this point, so we’re actually just learning everything on our own and going to the competition.

[34:32] Shannon O’Donnell: Any desire to collaborate with other teams or universities, or is it more individual because of the competition?

[34:40] Hong Wee Lim: Because for them, an engineering degree is a whole course, a three or four-year degree, sometimes it’s difficult for them. There are universities, like the University of Michigan, that have wanted to host us for the competition, but it’s more about the competition period rather than learning together. Learning together can be difficult because of timeline differences, and if it’s a long-term course. We need to learn a lot of things. We require costs to be set up rather than just learning ad hoc.

[35:19] Shannon O’Donnell: So, for the final question: is there anything else? Do you have any advice for students or for Siemens? Anything that we’re doing that’s working well to help support you. Anything else you need?

[35:20] Hong Wee Lim: I would say that for students who have a passion for engineering, this project is definitely a very good platform to start with, as you expose students to all practical engineering and actually train them to become better people. The feeling of being able to build a race car from scratch and drive it is really rewarding.

[35:52] Shannon O’Donnell: That’s great. So, a lot of the time, the competition teams I’ve talked with don’t have someone on staff from the university who’s really coaching, mentoring and doing what you are doing, which is incredible. I’m sure your students are beyond grateful for that. Anything thoughts or anything you would want to say to encourage any other faculty members or graduate students to support these teams?

[36:21] Hong Wee Lim: Having someone with experience to support the team is very important because, as I mentioned, the teams come and go, and knowledge transfer is very important. We build our knowledge transfer into documents, but there’s so much information that it can be difficult for younger students to read. We’re now trying to manage that documentation. That’s why it’s important to have a person there to make sure the students are doing the right things and transferring the right knowledge—not passing on bad stuff. Sometimes, in a rush, there can be bad practices, so it’s very important to have a faculty member in order to make sure things run smoothly. Of course, it would be good if the faculty member or graduate students were part of the team before. For example, I’m from the team, so I understand well. If I were to get someone who is not part of the team, it’s quite tough to even pick up the knowledge, to be on par with the students. For Formula SAE, we’re sometimes doing so much development that it can help generate academic papers as well. It’s good for the faculty member to be part of the team because the students are like the workers—you can get them to do the stuff, and that’s where the researchers would be able to generate papers. Overall, it’s actually good for the car as well [37:51 inaudible].

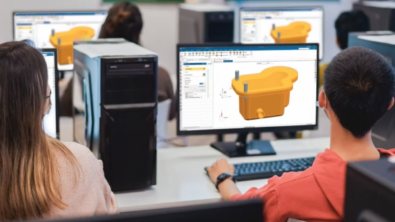

[37:53] Shannon O’Donnell: The only other thing we didn’t ask specifically in the interview, you’re using Siemens software. Can you tell us a little about what software you’re using and if there’s been any good story or anything you’d like to share along those lines?

[38:08] Hong Wee Lim: We are using STAR-CCM+ from Siemens for our computational fluid dynamics (CFD) simulations for the car body shell. We are very glad that Siemens sponsors us with the license to use the software. In fact, they helped us connect it to our high-performance computing cluster, which allows us to run a lot more simulations due to the increased computational power. Siemens has provided excellent support. Since it was a new software that no one had used before, they offered a lot of mentorship and support. Even connecting the software to the high-performance computing cluster had issues, but they always helped us connect with the IT cluster guys. From there, we started using the software more and started to break down the simulation into different components. The car is just one piece, but we have multiple students and limited time, so we can’t always run full-car simulations. Instead, we break it down into different parts. We actually have weekly, bi-weekly and monthly time plans for running specific component simulations. After that, joining them together for a full simulation and discussing what is good and what’s not in terms of the results. Then, we do validation with sensors on the car and validate it back to the simulation and adjust the simulation so that it matches the real-world data that we have.

[39:43] Shannon O’Donnell: Thank you for joining us on this episode of Innovation in the Classroom. To learn more about Formula SAE and its Singapore division, please check the show notes. If you liked what you heard today, subscribe to our podcast and stay tuned for more episodes of Innovation in the Classroom, wherever you get your podcasts. I’m Shannon O’Donnell and thank you so much for listening.