Rethink engineering education with real-world technology

How do you make students more employable? How can colleges and universities increase placement rates? How can companies fill jobs with employees well-trained and highly-skilled?

To answer these questions, colleges and universities must proactively redesign and augment courses so their students get the real-world learning benefits they need to launch into successful post-graduation careers.

Technical skills are often the most sought-after and hardest to fill. As university engineering programs around the world grapple with how best to prepare their students for digitalization and Industry 4.0, it’s clear that there’s no substitute for hands-on experience.

To produce graduates who are ready to be productive right out of the gate, schools increasingly find that they need to:

• Educate engineers in future-oriented, comprehensive software with a role-based user experience so they can use their skills quickly to learn and leverage new technologies in the real world.

• Provide key teaching methods integrated with digital product development and lifecycle management technologies so students know how to apply technology to solve problems.

• Take the theory to the shop floor for real-world experience so students have practice in problem-solving, not just a theoretical understanding.

Schools such as the Norwegian University of Science and Technology (NTNU) and the Ostwestfalen-Lippe (OWL) University of Applied Sciences in Germany complement theoretical work with a learn-by-doing approach. This level of hands-on work is performed with the help of different industry-standard software, including Siemens’ software.

These universities are amongst the many institutions rethinking engineering education by providing tools to the next generation of engineers in a real-world team and project environment. These schools are enabling students to become true innovators even while they are still in a degree program and giving them not only the experience needed to find a job, but ensuring they can contribute immediately to a company’s success.

NTNU

NTNU is the primary institution for educating engineers and scientists in Norway. The school’s motto is “The Creating University,” and its objective is to develop engineers who are prepared to make an immediate and productive contribution upon graduation.

Computer-aided design (CAD), computer-aided engineering (CAE), computer-aided manufacturing (CAM) and other advanced technologies are essential to achieving the university’s goals.

“The risk involved in radical innovation is high, but we want to apply high-end CAD/CAE/CAM tools to generate knowledge in the fuzzy front-end of product development, where the right decisions lead to high customer value and competitive edge,” said Professor Terje Rølvåg, who works in the department of engineering design and materials (IPM) at NTNU.

Rølvåg added that the school uses Teamcenter in the Shell ECO marathon and Formula Student competitions, and that “the outcomes have been excellent.”

By deploying a system that can connect people and processes with a digital thread, the university has incorporated product development and PLM technologies across its teaching curriculum and research programs. Teamcenter has become the essential collaboration tool for both the engineering faculty and students.

Using the same software many innovative businesses use has also enabled students to focus more on research and construction, and less on hypothetical programs. By using PLM tools to gain economies of scale, there have been notable efficiency gains, especially relative to administering the curricula.

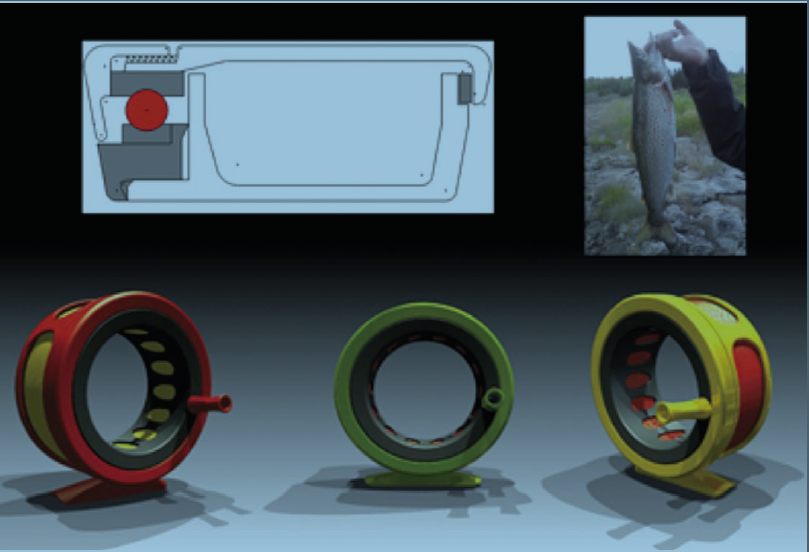

IPM students designed these fishing reels in one of their hands-on engineering classes.Hands-on experience with problem solving

IPM students designed these fishing reels in one of their hands-on engineering classes.Hands-on experience with problem solving

Faculty at the university now have more time to develop and exploit an advanced problem-solving teaching approach, which helps educate future engineers on how to address challenges with innovative and sustainable manufacturing.

Rølvåg said that a number of studies have shown that the most successful students are those who know how to use PLM tools in capturing and reusing knowledge. Students that know how to use product development and lifecycle management tools in combination with lean principles can achieve great results in the classroom and carry the skill into the workplace.

“Our students get a comprehensive theoretical education and real-world training in advanced engineering tools, enabling them to be creative in developing products.”

Their skills and work have generated new patents, products and entrepreneurship, as well as new processes in leading companies. Rølvåg insists that having consistent access to new and groundbreaking tools are essential to advancing educational efforts that foster student innovation and deliver solutions beyond the university.

Students also designed the Easy Roller II, a 100 percent universal designed plastic wheelchair. It could be used in airport scanners, swimming, or in hospital testing rooms that use magnets.

Students also designed the Easy Roller II, a 100 percent universal designed plastic wheelchair. It could be used in airport scanners, swimming, or in hospital testing rooms that use magnets.

OWL

Andreas Deuter, professor of computer science in technology and production at OWL, teaches in the department of production and economics, which includes logistics, wood technology and production engineering.

Deuter says that ongoing digitalization affects this field as much as electrical engineering, computer sciences, machine technology and mechatronics.

“Consequently, our students need a profound understanding of digitalization for their future professional lives, and we are providing this.”

Andreas Otte is a scientific officer at the department of production and economics at OWL. He said that a digital, networked world impacts the way new things are designed and built so they’re both compliant and commercially successful.

“We therefore have students form teams acting in lifelike roles such as designers, produc¬tion or quality managers to perform a comprehensive task covering the entire application lifecycle,” he said.

To provide students with a framework that supports this approach, Deuter introduced them to Polarion ALM. His team had been using the software in a previous position, and he liked it because they had the support to create products covering requirements for documentation and traceability, so he transferred the product to the university.

OWL now has a cutting edge Industry 4.0 lab that supports important methods for digitalization on the shop floor, such as additive manufacturing and digital twins for both products and production, giving their students the opportunity to gain real-world experience while still in the classroom.

“Part of our efforts toward research and implementation of smart product creation is the project PLM/ALM for smart products,” Deuter said. “In this cooperative project with Siemens, we combine ALM for software and PLM for other product and production aspects to streamline overall mechatronic product creation.”

By converging PLM and ALM software, students were able to overcome common issues with separate requirements management, interrupted traceability and disconnected project management.

SmartFactoryOWL is a cutting-edge lab environment where students can research and implement projects using communication-based automation technology.

SmartFactoryOWL is a cutting-edge lab environment where students can research and implement projects using communication-based automation technology.

Final thoughts

Universities worldwide are adapting to the needs of their students and the workplace environment they will likely encounter. The advantages of offering hands-on experience by applying the software being used at some of the most innovative companies proves to be a catalyst for closing the skills gap and filling the open engineering positions.

Stay tuned for more stories about how universities are breaking down the old ways of educating engineering students to ensure they’re ready for a digital workplace.

About the author

Dora Smith is the senior director of the global academic program for Siemens PLM Software, a business unit of Siemens Digital Factory Division. Under Dora’s leadership, the global academic program is now a company-wide strategic initiative for the company. The program empowers the next generation of digital talent through project-based learning, STEM competitions and industrial strength software and curriculum to support more than 1 million students and more than 3,000 institutions worldwide. Dora is an accredited business communicator with more than 20 years of experience. Previously, she held executive management positions at CAD Potential (now part of Tata Technologies), where she developed the company’s first academic and certification programs. Prior to that, she directed the Unigraphics Users Group (now PLM World) an independent, not-for-profit organization supporting the engineering community. She also served as president on the board of directors of IABC St. Louis. Dora earned her bachelor’s degree in journalism from the University of Missouri-Columbia and a master’s degree in business administration from Washington University.