“We found the results were 30% more accurate than our previous methods.”

> Read the full case study on how GKN Aerospace Engines increased their planning accuracy

Global aerospace engine supplier deploys Siemens solution to identify production bottlenecks and lower costs.

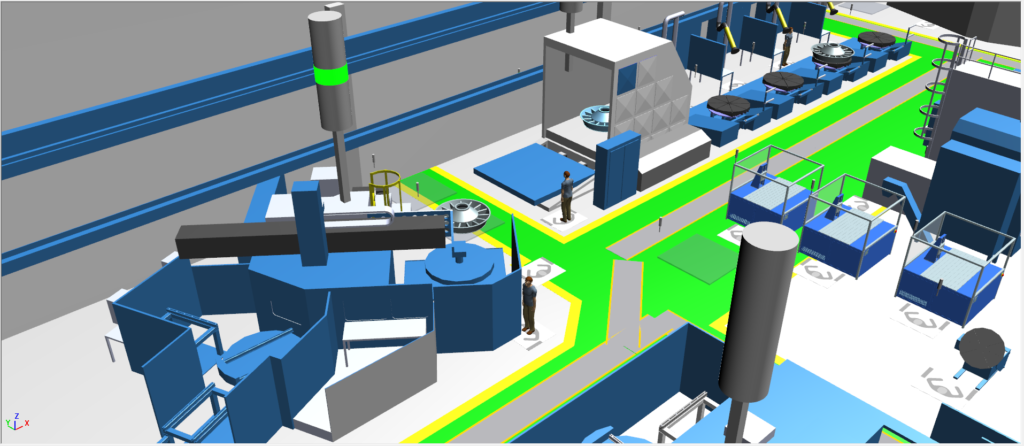

GKN Aerospace Engines, a business line of GKN Aerospace, needed a better tool to plan and optimize their production process and production equipment investment – a tool that would aid in strategic planning, and handle real-life complexity to accurately predict lead times and consider variation. GKN Aerospace needed a new avenue to meet customer delivery expectations and identify any existing problems that could be solved before they became unmanageable. In addition, some value streams share production resources between different products, which cause crossing material flows.

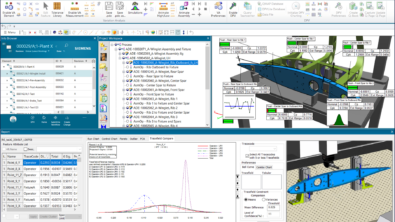

Recognizing a clear need to make their current processes more efficient, while also considering expected future production volume increases, GKN Aerospace decided to conduct a pilot program using Tecnomatix Plant Simulation software from Siemens. Plant Simulation enables users to define a virtual model of a production plant, with all its characteristics and interdependencies, and use it to simulate actual production. Tecnomatix is a part of the Xcelerator™ portfolio, a comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software.

“We started to use Plant Simulation as we needed a better strategic planning tool to analyze and plan production capacity,” says Alexander Hall, MOM-MES Architect, GKN Aerospace Engines Business Line, TI-IS. “Given the combination of increased forecasted production volumes and the complexity of our production process, we have realized that the static capacity analysis tools we were using were not accurate enough.”

“We found the capacity and utilization results obtained with Plant Simulation were 30 percent more accurate than our previous methods.” – Ragnhild Hansen, Project Engineer, Kongsberg Site, GKN Aerospace Engines Business Line