Realize LIVE 2019: The Digital Twin in Action

This is the second in our blog series featuring three Realize LIVE 2019 session and demonstration themes in the Tecnomatix track: Electronic Vehicle Manufacturing, Industries, and Digital Twin in Action. Last week we wrote about the Electronic Vehicle Manufacturing sessions and demos. Today we’ll tell you about the sessions and demonstration events highlighting The Digital Twin in Action.

Check out what we have planned and register to attend our big event, June 10-13 in Detroit, Michigan.

Monday, June 10

Business Process Breakout Session: Dimensional Variation Analysis at Ford Motor Company

In this session you will hear about how Ford Vehicle Operations Manufacturing Engineering uses VisVSA when they engineer new model vehicle product designs, assembly processes, and tooling using VisVSA.

Presenter: Andre Jurkiewicz and Matt Maier, Ford Motor Company

Date: Monday, June 10, 10:00am – 10:45am, Room 250B

Demonstration:Intosite – Your Entry to the Digital Twin

In today’s industrial world more and more companies are adopting the Manufacturing Digital Twin – a complete digital model of the factories along with their related planning and operational processes. Such technology will mesh information coming from engineering systems, execution systems and IoT, and will equip the enterprise is with the tools to dramatically improve and optimize its entire manufacturing cycle. Siemens PLM is your partner for that, providing a suite of tools, technology, and consultation to get you there. However, getting there is a journey, a journey that many companies has started or are about to start taking. In this session we will present Intosite as a fast entry point into the Digital Twin, showing how you can get to an initial scope of your Digital Twin here and now. Intosite is a Web based technology that enable s you to capture a visual model of your factories worldwide in a pragmatic manner and connect from that visual model with a verity of systems; PLM systems, other enterprise systems and legacy systems. It enables people with an easy way to start engaging with the Digital Twin today, and it is you companion along the journey for a gradual adaptation of the Digital Twin.

Learning Objectives:

- Increase productivity and proficiency with current/future software

- Learn new and exciting product features

- Learn about different use cases and applications

Presenter: Vlad Murashkin, R&D Lead, Siemens Digital Industries and Trevor Bengtsson, Applications Engineer, Siemens Digital Industries.

Date: Monday, June 10, 10:00am – 10:45am, Room 335

Breakout Session: Extending Teamcenter into Manufacturing

In this session you will learn how to extend Teamcenter into manufacturing planning and engineering to close the digital gap from product design to production execution for your business and for your customers. You will see how you can leverage Teamcenter for multi-BOM and manufacturing data management, process planning, electronic work instructions, and production optimization, along with Tecnomatix process validation tools for more complete process plans that better describe how to build what you are building, when and where you need to build it.

Learning Objectives:

- Increase productivity and proficiency with current/future software

Presenter: Kevin Thompson, Siemens Digital Industries.

Date: Monday, June 10, 11:15am – 12:00pm, Room 336

Breakout Session: Engine Manufacturing Feasibility using Flex VSA

Recent trends in the development of high-performance automotive engines have resulted in lower weight powertrain components with tighter tolerance specifications. This has resulted in better fuel economy but presents a manufacturing challenge with more flexible components and tighter tolerances. This necessitates finer validation of the design prior to manufacturing.

Allocation of dimensional tolerances has traditionally followed a rigid body process while conventional FEA has been used to evaluate specific worst-case deflections without taking statistical variation into account. A more robust approach is needed.

This presentation will show a new use case for flex Variation Analysis (Flex VA) using prismatic automotive engine components, rather than the typical sheet metal applications seen in the past. Flex VA can combine component meshing and load definition with traditional VA in a single environment to ensure that all top-level specifications such as preventing shaft binding within a set of bearings are met. Having this capability in a single tool means that multiple trade-off studies can be evaluated earlier in the design cycle when changes are less expensive to implement.

Learning Objectives:

- Increase productivity and proficiency with current/future software

- Learn new and exciting product features

- Optimize the use of existing software

Presenter: Dave Doody, co-presenters: Youssef Ziada, PhD, Technical Expert (Digital Manufacturing), Ford Motor Company, Jerry Lai, CAE Engineer, Ford Motor Company.

Data: Monday, June 10, 1:30pm – 2:15pm, Room 335

Tuesday, June 11

Breakout Session: Optimizing the Asset Lifecycle with IBM and Siemens

In this session you will see how IBM and Siemens are enabling continuous improvement of assets from engineering and manufacturing to operations and maintenance.

Siemens and IBM are integrating the Siemens Digital Innovation Platform with the Maximo® portfolio to enable a closed loop digital thread bridging engineering to maintenance and operations. Together these capabilities will allow OEMs and owner/operators to optimize the end-to-end service lifecycle management of assets improving data quality, reducing downtime and driving continuous improvement of products and processes. Join us to learn more about how the Siemens Digital Innovation Platform and the Maximo® portfolio will provide significant value across the value chain.

Learning Objectives:

- Identify solutions to meet business challenges

- Increase productivity and proficiency with current/future software

- Network one-on-one with other users and industry leaders

Presenter: Brian Johnsen, Manufacturing Engineering Software Product Manager, Siemens Digital Industries and Greg Knowles, IBM.

Date: Tuesday, June 11, 11:15am – 12:00pm, Room 335

Breakout Session: Virtual Reality in Manufacturing Planning and Validation

In this interactive demonstration session, you will learn how to use Virtual Reality with Tecnomatix Process Simulate applications for improved manufacturing planning, validation and collaboration. You will learn how to set up the software with an HTC Vive virtual reality headset and see how models are loaded into the virtual reality environment for use in planning, simulation and validation.

Learning Objectives:

- Learn new and exciting product features

- Increase productivity and proficiency with current/future software

Presenter: Shay Shomroni, Director Business Development, Siemens Industry Software.

Date: Tuesday, June 11, 1;30pm – 2:15pm, Room 336

Breakout Session: Intosite at Ford: An Overview

An overview of the utilization of Intosite at Ford as viewer, communication tool, and portal to the Digital Factory.

Learning Objectives:

- Identify solutions to meet business challenges

- Innovative strategy to digitalize business

- Increase productivity and proficiency with current/future software

Presenter, Paul Coffman, Jr., MS, PhD, Technical Leader, Ford Motor Company; Co-presenter: Vlad Murashkin R&D Lead, Siemens Digital Industries.

Date: Tuesday, June 11, 2:45m – 3:30pm, Room 336

Thursday, June 13

Breakout Session: Model-based Quality for GD&T (PMI) Design and Realization

This session will offer an overview of the Model-Based Quality workflow and use cases for closed-loop GD&T (PMI) design and realization, as well as quality inspection planning. You will learn about what’s new in the Siemens manufacturing quality solution offering for Variation Analysis (VSA), Dimensional Planning and Validation (DPV), Product and Manufacturing Information (PMI) Manager, and CMM Inspection. There will be an opportunity for customer interactions and Q&A during the session.

Learning Objectives:

- Identify solutions to meet business challenges

- Learn new and exciting product features

Presenter: John Zhang, Manufacturing Engineering Software Business Lead

Siemens Digital Industries; Co-presenter: Tom Kalkman, Manufacturing Engineering Software Product Manager, Siemens Digital Industries.

Date: Thursday, June 13, 10:00am – 10:45am, Room 336

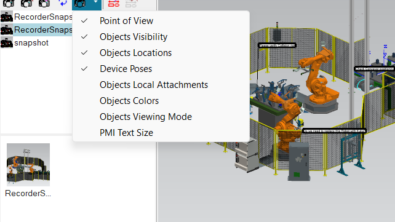

Demonstration: Extending NX into Factory Layout using Line Designer

In this interactive demonstration session, you will learn how to use NX Line Designer to build new or refurbish existing production facilities rapidly. You will learn about the administrative tasks associated with library creation and the use of Product Template Studio with NX Open. Demonstrations of rapid line creation using NX Line Designer and integration to validation and optimization tools, such as Process Simulate and Plant Simulation, will be offered.

Learning Objectives:

- Learn new and exciting product features

- Operate specific software modules with hands-on-training exercises

Presenter: Kristy Meyers, Manufacturing Engineering Software Product Manager, Siemens Digital Industries.

Date: Thursday, June 13, 10:00am – 10:45am, Room 335

Breakout Session: Teamcenter for Manufacturing and Service Roundtable

Join us for an interactive discussion about Teamcenter for Manufacturing and Service application topics. Ask the experts the questions that will help you to better understand the full suite of applications available in Teamcenter to support digitalization of manufacturing in your organization. Topics for discussion may include assembly process planning, electronic work instructions, multi-BOM management, production process planning, and service engineering.

Learning Objectives:

- Network one-on-one with other users and industry leaders

- Bring together customers, partners, and thought leaders to create a dedicated space for knowledge sharing

- Identify solutions to meet business challenges

Presenter: Kevin Thompson, Siemens Digital Industries; Co-presenter: Brian Johnsen, Manufacturing Engineering Software Product Manager, Siemens Digital Industries.

Date: Thursday, June 13, 11:15am – 12:00pm, Room 336

Breakout Session: Investing in Simulation 101

While simulation is well-established during product design and verification, many industrial organizations today are still not employing this powerful methodology in the most critical stage of their value chain: manufacturing of the product. As a result, they lose opportunities to study the behavior of their manufacturing processes and systems before they are deployed. Since commissioning of new facilities, production lines and processes are often costly and capital-intensive, applying simulation methods to manufacturing can yield enormous benefits. Many (like you) understand the endless possibilities simulation tools offer to drive immediate, tangible improvements and reduce inefficiencies and costs on the production floor and beyond. But not everyone in your company is convinced. It is clear that the biggest obstacle to starting a project or acquiring new software is funding. Therefore, I want to share my experience in this arena with some of the best practices my team has seen used successfully to overcome this challenge when it comes to simulation.

In this session, we will address:

• The most common objections (and the right rebuttals)

• Are you sabotaging yourself?

• How to make use of your sales consultant

• How a business plan should be constructed

• Strategies that have worked for others

This session will include a demo of the Siemens Tecnomatix Plant Simulation tool, highlighting its greatest value-add capabilities and features. Q&A will end the session. Participants will leave with a broad repertoire of strategies and techniques to get internal funding to invest in their simulation projects.

Learning Objectives:

- Bring awareness and clarity to business challenges

- Identify solutions to meet business challenges

- Increase productivity and proficiency with current/future software

Presenter: Carlos Ortega, Engineering USA

Date: Thursday, June 13, 1:30pm – 2:15pm, Room 336

Breakout Session: Extending Teamcenter into Service Engineering

In this session you will learn how to extend Teamcenter into the development and delivery of service solutions for your business and for your customers. You will see how you can leverage a strong configuration management and data management backbone into the definition of service plans and the definition of physical structures. We will share how best to leverage the data created and collected during the design, engineering, and manufacturing into service and show how linking service with engineering enables automatic validation of installed parts and improves engineering analysis of failures, changes, and proposed upgrades.

Learning Objectives:

- Increase productivity and proficiency with current/future software

- Optimize the use of existing software

Presenter: Kevin Thompson, Siemens Digital Industries; Brian Johnsen, Manufacturing Engineering Software Product Manager, Siemens Digital Industries.

Date: Thursday, June 13, 2:45pm – 3:30pm, Room 336

Register now to attend these sessions and demonstrations.

Follow this link to the full agenda.