Products

Realize LIVE: Tecnomatix in Industries

This is the third in our blog series featuring three Realize LIVE 2019 session and demonstration themes in the Tecnomatix track: Electronic Vehicle Manufacturing, Industries, and Digital Twin in Action. Our previous posts covered the Electronic Vehicle Manufacturing and Digital Twin in Action events.Today we’ll tell you about the sessions highlighting Tecnomatix in Industries.

Check out what we have planned and register to attend Realize LIVE, June 10-13 in Detroit, Michigan.

Monday, June 10

Session: Product Realization for the Aerospace and Defense Industry  Michael Walker

Michael Walker

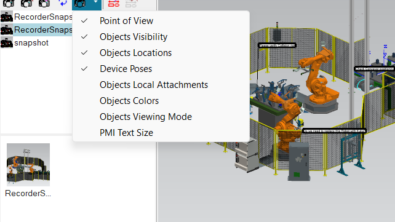

This session will focus on the benefits of digitalization in manufacturing for the aerospace and defense industry. Primary focus will be on product realization, key characteristics (PMI), trace-ability, and service engineering. Future factory and Industry 4.0 topics will also be discussed.

Learning Objectives:

Strategize to meet current industry trends using Siemens solutions

Identify solutions to meet business challenges

Innovative strategy to digitalize business

Presenter: Michael Walker, Portfolio Development Executive, Siemens Digital Industries

Date: Monday, June 10, 1:30 PM – 2:15 PM, Location: Room 336

Session: Integrated Manufacturing for the Automotive Industry Todd Bengtsson

Todd Bengtsson

This session will focus on the benefits of digitalization in manufacturing in support of integrated manufacturing for more predictable program launches in the automotive industry. To facilitate the new manufacturing strategies required in today’s automotive market, leading automakers must implement a collaborative approach that integrates engineering and manufacturing in the development of the launch process. This approach allows for early access to product engineering data so that manufacturing operations work in parallel and processes can be planned, optimized and validated concurrently with design. In this session you will learn how Siemens manufacturing solutions can help to implement such an integrated approach to increase the efficiency of deploying a modular platform that allows for a more predictable launch operation, and that provides management with clear visibility into program performance.

Learning Objectives:

Strategize to meet current industry trends using Siemens solutions

Increase productivity and proficiency with current/future software

Innovative strategy to digitalize business

Presenter: Todd Bengtsson, Director, Siemens Digital Industries

Date: Monday, June 10, 2:45PM – 3:30PM, Location: Room 336

Session: Collaborative Manufacturing Heavy Equipment Makers

The current trends of global production and product complexity are having a major impact on heavy equipment manufacturers. In this session, we will discuss how Siemens Digital Manufacturing Solutions can help companies navigate these trends by enabling collaboration between different disciplines across the organization. We will show how Siemens’ open approach and fully integrated Digital Manufacturing portfolio can be leveraged to improve manufacturing efficiency and to take advantage of opportunities in the marketplace.

Learning Objectives:

Address current business challenges using Siemens solutions.

Analyze current industry trends that will impact the future.

Identify ways to digitalize the Heavy Equipment business.

Presenters: Dave Introcaso, Manufacturing Engineering Software Business Development

Siemens Digital Industries

Co-Presenter: Sanjay Rajan, Siemens Digital Industries

Date: Monday, June 10, 10:00AM – 10:45AM, Location: Room 336

Wednesday, June 12

Session: Train & Educate with Plant Simulation – Oakland University Robert Van Til PhD

Robert Van Til PhD

Oakland University’s Industrial and Systems Engineering (ISE) Department has been an academic partner of Siemens PLM since 2011. Since that time, several Tecnomatix tools (Plant Simulation, Jack, Process Simulate Robotics) and Teamcenter have been integrated into courses in its undergraduate and graduate Industrial and Systems Engineering, Engineering Management, and Systems Engineering degree programs. This presentation will demonstrate how the ISE Dept. uses Plant Simulation to provide Industry 4.0 education not only to its students, but also to working engineers engaged in lifelong learning through both graduate degree and non-degree programs. Plant Simulation has been integrated into several courses to enhance the students’ educational experience by providing industry relevant assignments that demonstrate course concepts. After an assessment of the use of Plant Simulation in its courses, the ISE Dept. found that many students desired to take a deeper-dive into the use of Plant Simulation. This led to the creation of a new course titled PLM Applications – Throughput Simulation. This course provides a combination of both training and education by teaching details on how to operate Plan Simulation as well as by using Plant Simulation to complete various hands-on throughput simulation assignments.

Joe Finkelstine

Joe Finkelstine

Learning Objectives:

Strategize to meet current industry trends using Siemens solutions

Identify solutions to meet business challenges

Identify source for industry-ready engineers

Presenter: Robert Van Til, PhD, Professor and Chair, Oakland University

Co-Presenter: Joe Finkelstine, Siemens Digital Industries

Date: Wednesday, June 12, 1:30 PM – 2:15 PM, Location: Room 336

Read the complete event agenda here.