Building the Digital Thread for Harness Design

There’s no doubt about it: today’s smart, connected products are incredibly complex. They are composed of embedded software, custom processors, flexible circuit boards, sensors, antennas, and complicated electrical harnesses. And while the real-world products are complex, their digital representations are even more so.

You see, every aspect of a smart, connected product has one, and perhaps many, digital representations that have evolved over time. The progressive iterations of those digital representations strung together into a single sequence are called a Digital Thread. A Digital Thread exists for each and every aspect of a smart, connected product. One also exists for every assembly and even the overall product.

Managing the Digital Thread for all these items is critically important. It allows organizations to manage the configurations of products. It allows them to revisit the state of designs at a specific point in time. It allows companies to comply with some regulatory requirements. It is crucial for practically all manufacturers.

Today, in this post, we’re going to be diving deep into the Digital Thread of harnesses. We’ll answer many questions. What does it encompass? What does it look like over time? Who is involved?

Let’s get started.

The Many Design Representations of a Harness

To start to understand the Digital Thread of a harness design, you have to start by identifying all the different design representations that are involved. That includes:

- Logical Diagrams (ECAD):

These deliverables detail what wires connect which terminals on different electronic endpoints. They detail out some connectors if required. They also detail what signals are carried on which wires. All of this information is communicated, and kept up to date, with the routing in the 3D mechanical assembly.

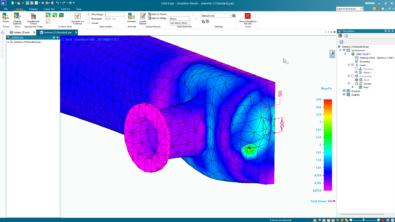

- 3D Mechanical Assembly Routing (MCAD):

In this representation, the wires are routed through the 3D mechanical assembly, connecting different electronic endpoints. This must stay in synch with the logical diagram as they represent the same information, just in different contexts.

- Harness Components and Drawings (MCAD):

The 3D mechanical assembly holds all of the wires routed through it. However, each harness and the wires it contains must be pulled out and isolated for documentation purposes. Individual harnesses, which become individual parts, are flattened to create a nailboard layout, which serves as instruction documentation for assembly work.

- Bill of Material (ECAD / MCAD):

This listing of all the wires (and their lengths) bundled into harnesses and their related connectors is used for procurement and manufacturing purposes. It is often shown on the harness drawings.

Each of these items will have their own Digital Thread, the progressive sequence of iterations. They each have to be managed. Yet, there is more complexity to take into consideration.

The Interconnected Network of Design Representations

Another complicating factor to consider when thinking of the Digital Thread of a harness is the interconnected nature of these design representations.

- Diagram-to-Routing Relationships:

Logical diagrams and the routing through the 3D mechanical assembly must be associatively connected because they contain some of the same information. Each, for example, have wires going from an electronic endpoint to another electronic endpoint.

- Routing-to-Component Relationships:

Each harness component has a tie back to the routing through the 3D mechanical assembly. Their lengths must match exactly, as do other wire characteristics, such as color, etc.

- Drawing-to-Component Relationships:

The flattened harnesses and their corresponding drawings are tightly connected to the harness component. Those lengths are the same. They just have been flattened. The drawing is just a view of that flattened harness with additional information.

- BOM-to-Diagram / Routing Relationships:

The Bill of Material must correspond exactly to the component information held in the logical diagram and the routing through the 3D mechanical assembly.

So while each of these items has their own Digital Thread, there are connections across each of these Digital Threads. That is a critical aspect that must be captured.

Tracking Iterations across Digital Threads

There is one last complication in this discussion of Digital Threads that need to be discussed: design iterations.

Each of these design representations has numerous iterations, representing the progressive development of the design. Past iterations are kept in case engineers need to step back to a prior state and continue on a different branch of exploration. This is true of practically all design work.

This reality factors strongly into Digital Threads of all kinds, but especially for harnesses due to their cross connections. The following questions expose the importance in this context.

- Which iteration of the logical diagram does the routing through the 3D mechanical assembly represent? Was it 1.3, 1.4 or 1.5?

- Which iteration of the routing through the 3D mechanical assembly does this harness component represent? Was it 5.1, 5.3 or 6.2?

- Which flattened harness component does this nailboard drawing represent? Is it 1.0, 2.3, or 2.4?

So while it is important to know that there are cross-connections between the Digital Threads of different design representations of a harness, it is just as important to know which iterations are connected to which iterations. Without that information, traceability is not granular enough for meaningful insight.

A Last Note on Importance

Why is all of this important?

There are circumstances in development when a company must revisit specific deliverables at a certain point in time. It might be a prototype failure. It might be a change order. It might be a dispute with a supplier. It might be a process audit. It might be a compliance check with regulations.

At those times, it is critical to be able to go back and identify exactly what interconnected network of design representations was used for those activities. If that information is not accessible, then the organization may not be able to identify the root cause of a problem or could be fined by a regulatory organization.

In short, it is critically important.

Recap

- A Digital Thread is the progressive iterations of digital design representations. The Digital Thread of a harness is complex.

- Harnesses, logical diagrams, routings through 3D mechanical assemblies, harness components, harness drawings, and Bills of Materials each have their own Digital Thread.

- Just as importantly, there are cross-connections between the Digital Threads of the individual items in a harness. Furthermore, these cross connections relate specific iterations of those design representations.

- Tracking and managing the Digital Threads for a harness is critically important for organizations to revisit specific deliverables that were used for specific applications. This is important for prototype failures, change orders, supplier disputes, process audits, and regulatory compliance.

In my opinion, managing the Digital Thread of harnesses is critically important. What’s your take? Leave your feedback in the comments below.

Comments