A CAD Admin Perspective on ST9 Beta Training

Melissa has achieved Solid Edge rock star status for the last couple of years because of the last two presentations she has given at Solid Edge University. She has converted a lot of users to synchronous technology, and used these presentations to make public the quantified results. It’s not just a compelling story, the numbers really back up the claimed benefits of synchronous technology.

So while Melissa was in Huntsville, we talked over lunch about why it is important for CAD Administrators to keep up on the latest offerings from their CAD vendors.

==============================

First of all, I need to get this straight, is it CADmin, CAD admin, or CAD Admin?

It’s CAD Admin with a big A.

How long have you been a CAD Admin?

About 5 years now. I kind of fell into the world I’m in now by knowing how to fix broken files. And because I was able to fix them, the management said “hey, we didn’t know we had a resource in you, maybe we should start developing that resource”. In the meantime, the company had grown to the point where having everyone do their own thing wasn’t working. They really needed someone to start setting standards and establishing best practices to get some consistency.

So that’s how I wound up being a CAD Administrator. I was a designer and transitioned to CAD Admin role. Then in 2014, I moved to The Robbins Company. We make tunnel boring machines, or TBM for short.

I

That was a really interesting thing for me, something I guess I didn’t see coming. Getting to see a new product line – I had been with Joa (previous company) for so long that I knew the machinery, and I knew what it did. So when I got to Robbins, suddenly I had to learn a whole new machine type. It was really interesting. They’re huge. The product line is larger than life, it’s so huge. We do small stuff as well. We do machines that bore fiber optic tunnels, and things like that with a remote control boring machine. It’s an unmanned machine, controlled from the surface. And then we have stuff like what bored the English Tunnel where 25 guys can crawl up through the machine.

It’s so much fun, the product line is a blast. I’ve really enjoyed just from an engineering standpoint getting to learn what we do and what we make.

What is the most important job you have to do as a CAD Admin?

My number one priority day to day is to keep the users up and running. So before I can write training, before I can write best practices, my first focus is to keep everybody up and running every minute of every day. I don’t ever want Solid Edge and in this case Teamcenter to stop them from doing their work. I tell the users, if you’re not working, I need to know. We will fix it.

So you’re doing a lot of tech support?

Yeah. There are days when they break things faster than I can fix them. There are days when I leave the office further behind than when I came in in the morning, because more stuff has come in. It’s definitely a balancing act.

Are there other products that you support besides Siemens PLM products?

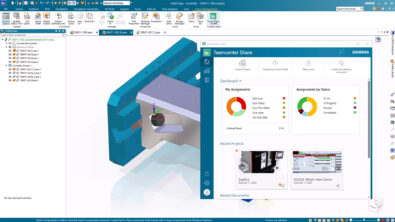

Yes, I do support some AutoCAD, Solid Edge, and we do have a Teamcenter admin who takes care of most of those issues. We use Teamcenter spread throughout the company. Purchasing uses it, project management uses it, and so that’s not strictly an engineering function anymore.

How do new versions of the CAD software affect your team’s productivity?

I test everything pretty extensively, so that when we transferred to ST7, we had zero minutes of downtime. It doesn’t mean that we never found a problem. We did. We found bugs and reported them, and we expect that to happen, because it is new software. But I do a lot of testing beforehand. I’ll test Solid Edge itself, I’ll test Teamcenter. We have a test installation of Teamcenter just to really be sure that we’re not going to have any problems.

But beyond that, I will pull out probably a half a dozen different new tools that are in a new version, and focus on it in a “What’s New” training session. I don’t tell them every tiny little new thing that’s in there, but I do tell them the things that are going to have to biggest payoff for us, you know, the biggest bang for the buck. During our sit-down training, I show them the 5 new tools that I think will be the biggest advantage for them.

How often do changes to the software force you to do best practice training?

We do best practice training as often as we can, usually a couple times a year. We will implement a new best practice based on a new tool. Like the Duplicate Component in ST7. So that one I introduced, and there was going to be a definite payoff for us with that tool. Then I took it a little further and did a little contest with all the users and it was “Show me your Duplicate Component application”, which got our users to show me a bunch of applications of that new tool that I hadn’t necessarily thought of. How many parts did you place? What kind of assembly did you use it on? And then I asked them to send me a picture.

Out of that submitted data we gave away some swag like Solid Edge shirts, or mouse pads or whatever. But from that, I was able to put together a document that said not only do we have this new tool with Duplicate Component, here are some ways in which we can (and have) use it. So I used their coworkers to help teach everybody and spread good ideas.

Who gets the most out of the ST9 Beta testing that you are doing this week? Is it you or Solid Edge?

I think it’s probably equal. We come out and spend a week beating up the new version. We try everything we can to try to break it. So far this week I have not had a crash, pushing the software with real Robbins data. So Siemens gets to fix problems before they are shipped to all customers, but Robbins benefits because specifically we get our problems fixed before the software ever officially arrives. Now I know for sure that we are going to be ok before we install this version for all our users. Once you get it released and get to about maintenance pack 3, we run through our test protocol, but at that point I’m already pretty confident that we’re not going to have any fatal flaws.

How does the beta process work?

I come to beta week with the CAD Admins of other companies who are also using Teamcenter. They call it “managed” week. We all get together and Siemens employees show us all the new tools that they have ready for us now. And then we go to the training room which has our stuff set up as much as possible like our environment back home, but with the beta version, in this case ST9, which we are testing. And we start using the software with our data, and logging IRs through GTAC. Those get handled by special staff that they have assigned to handle our problems that week.

We have an extra meeting on Tuesday morning which is just for the Solid Edge Embedded Client. They’ll show us all the new features and interfacing things that we need to know about. That gives us a whole new slew of things to test. Throughout the week, we will also get together with the planners for each environment (part, assembly, draft). Like, I’ll tell Art Patrick, the Duplicate Component thing you’re doing with blocks, you’re blowing my mind! This is amazing. This is the kind of thing that really helps us, or we’ll say you know this will be great, but it would be even better if you could add this particular feature.

We report the bugs while we’re working and testing here, and then they go upstairs and fix those bugs almost immediately. It’s great to see how quickly some of these fixes can happen. The bugs get fixed and the fixes get integrated into the software the next day. It’s very gratifying, and an eye-opening look into the development process at the same time.

Then on Friday, we have a wrap-up where each one of us goes separately into a big conference room and talks about our impressions of the new version of the software to a bunch of planners and developers, so basically a roomful of Siemens employees get to hear a summary of our reactions to the new version. They are listening and we just talk about our experience.

Beta is good face time. It’s a private session in that the other customers aren’t there, so I can talk about proprietary stuff. As a customer, this process makes me feel like Siemens cares. I know they are listening, and doing things. They get as excited about the new tools as we do. These guys really like what they do and they really want the software to be good.

Does Solid Edge University have a specific track for CAD Admin?

No. They do have some individual sessions for admins, but not a dedicated track. I would like to see tracks for beginner, advanced, and admin. I would also like to see a roundtable session for admins where we can tell you what kinds of things we are hearing about every day and what we’re not hearing. Admins are really the front lines of tech support. We hear it first, and if we can’t solve it, the issue goes to GTAC. Admins are really a filter for GTAC. So we’re a pretty good judge of the first line of support.

What sort of standardized training material do you use?

When I get a new user, we sit down off and on for a few days. Talk about a couple topics, try a couple tutorials. We do talk about company specific situations, we talk about our process and how we do things, but in the meantime I’m just trying to teach them good basic Solid Edge modeling. And for that, there really isn’t anything out there. That is part of the reason why the bigger companies have admins, to set best practices that are company specific.

If you could give one piece of advice to a fledgling CAD Admin out there, what would it be?

Get to know other CAD Admins and get to know Siemens. Spending time at beta like I’ve done this week is very valuable for me and for my company.

=============================

Many thanks to Melissa for sharing her thoughts with us, and to the folks in Huntsville that make this Beta magic happen.