What’s New in Simcenter 3D 2021.2?

Simcenter 3D is an integrated platform that combines multiple performance-critical simulation disciplines: structures, acoustics, electromagnetics, thermal, flow, etc. Each release brings new capabilities and greater accuracy to meet your simulation and analysis needs. Simcenter 3D 2021.2 is no exception. Enhancements in this release help you drive engineering innovation and are focused on four key dimensions:

Go Faster with Simcenter 3D

Simcenter 3D continues to deliver on the promise to help you be more efficient and more productive. How? With faster simulation modeling, simplified and intuitive simulation toolsets and rapid synchronization with all the different design teams in your organization. Here are some highlights of what is new in Simcenter 3D 2021.2 to help you go faster:

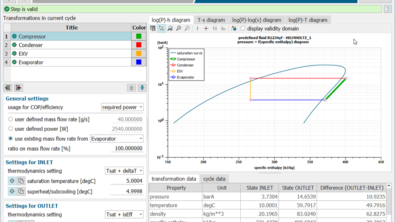

Turbomachines: Thermal Multiphysics Improvements

Approximation of Cooling Channels with 1D Immersed Ducts

New BC Interdependency Graph helps to quickly and easily verify that very complex boundary conditions are setup correctly

Automatically model and compute thermal protective layers, which makes post-processing easy

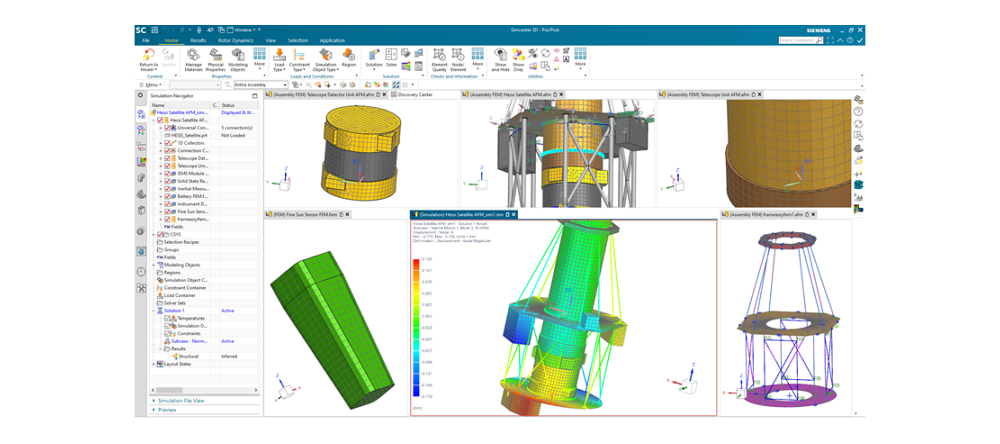

Multiple Tabbed Windows

View and interact with assembly and component parts simultaneously in separate windows to see how changes within the model impact other parts of the same model.

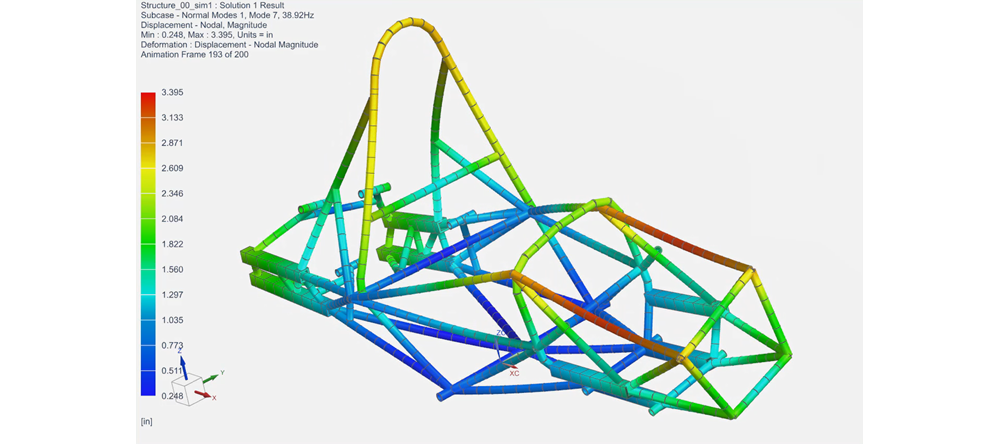

Structure Designer Beam Mesh Automation

Creating a beam-based model can be time consuming. NX recently introduced the Structure Designer tool, which helps designers rapidly create beam-based geometry structures. With 2021.2, Simcenter 3D Pre/Post can translate a beam model from Structure Designer into a 1D beam element model complete with cross sections to automate the beam model creation process and significantly reduce preprocessing time.

Create Microstructures for Injection Molded Parts

Import injection molded results into Simcenter 3D for multiscale analysis. This import will automatically map results to a structural mesh and creates microstructures to fit fiber orientations.

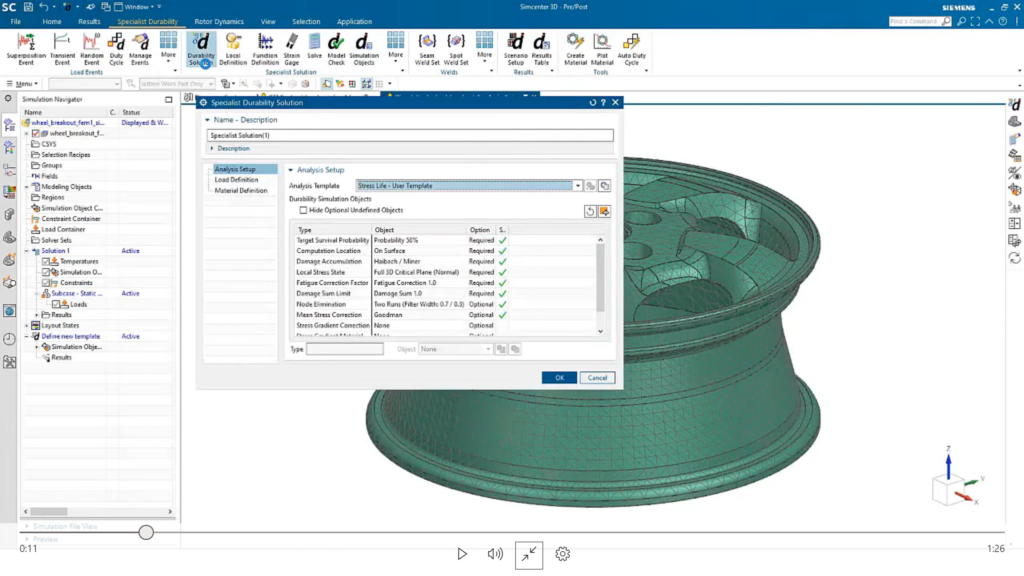

Durability Analysis Template

These new durability analysis templates allow you to apply the correct fatigue method with all solution settings already configured for your specific application needs.

Model the Complexity with Simcenter 3D

The broad multidiscipline integration of Simcenter 3D allows you to simulate real-world conditions more accurately, seamlessly transfer data and streamline multiphysics workflows. Here are some of the highlights from the 2021.2 release which expands the level of simulation complexity which can be achieved:

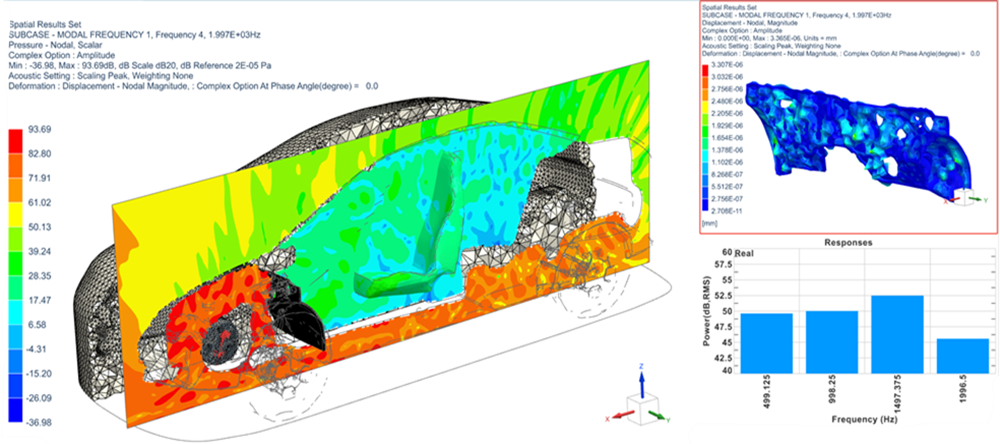

Sound Processing and Auralization

Auralization is the process of creating sound based on simulation data. This makes understanding and communicating acoustic simulation data straightforward as you can actually hear the results.

To better understand the effects of different transmission paths, support for convolute anechoic signals with simulation results has been added.

This will provide a more realistic reproduction of sound based on the sources changing environment, such as a loudspeaker in a car versus in your home.

Watch the video below and hear how Simcenter 3D reproduces audio playing in a vehicle.

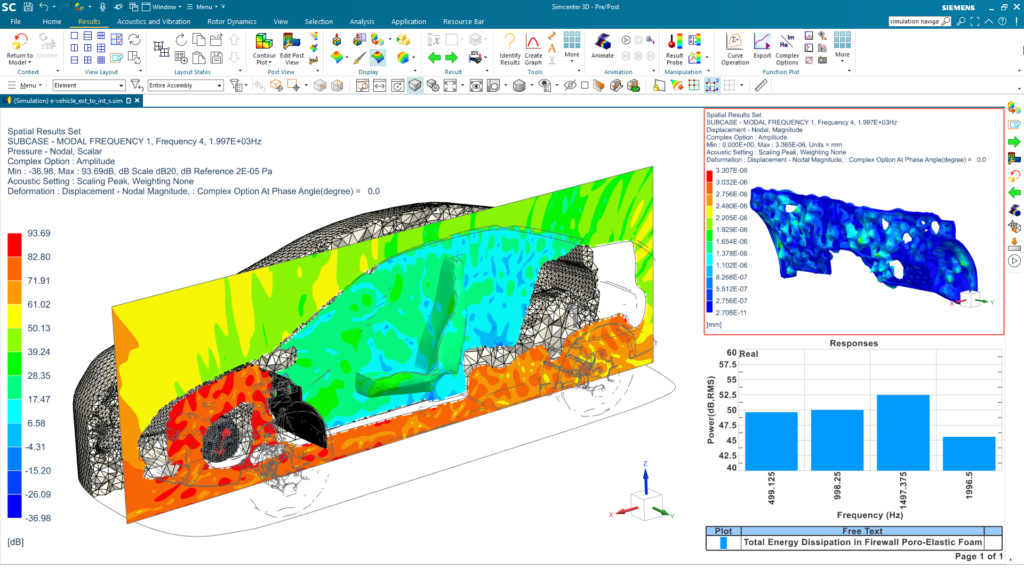

Trim Modelling Poro-Elastic Materials

Foams and other special materials need a more accurate physical description of their dynamics to account for structural, viscous and thermal losses.

With Simcenter 3D 2021.2, you can model and assess the effect of poro-elastic trim treatments with added support of Biot formulation for frequency-dependent visco-elastic and poro-elastic materials.

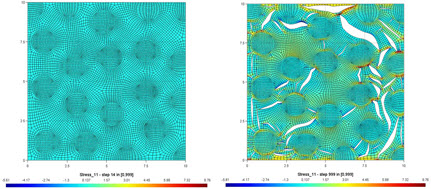

Rotor Dynamics: Axisymmetric Rotors and Stators

In many applications, rotors and stators are not necessarily symmetric. To account for this, the transient analysis of rotors and stators can now be non-symmetric in Simcenter 3D 2021.2. This allows for solving higher complexity models.

Temperature Dependent Thermo-elastic Model

Ceramic matrix composites and other high temperature application materials have variable properties at high temperatures which do not fit generalized material laws.

New and enhanced material models are available in Simcenter 3D 2021.2 for such high temperature applications. Tabular representation of materials with varying modulus, Poisson ratio, and coefficient of thermal expansion have been added.

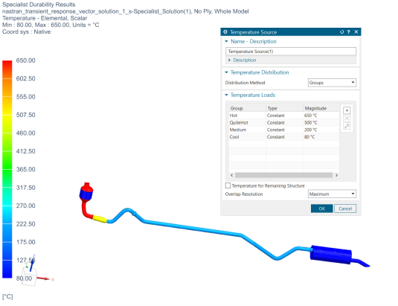

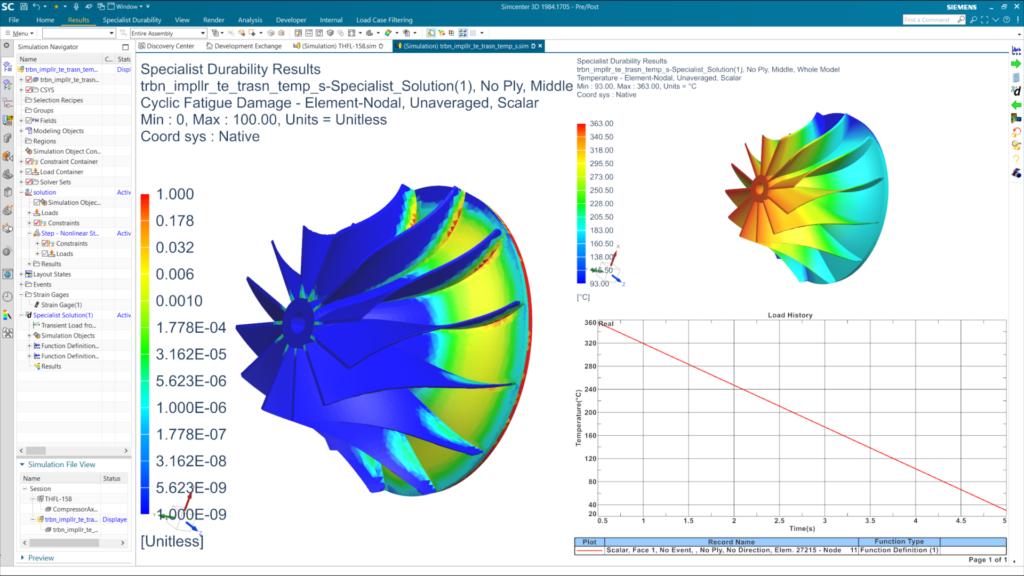

Thermal Fatigue

Temperature is an important factor in the behavior of structures. Simcenter 3D expands fatigue analysis to account for varying temperatures during the loading, as is the case in turbomachines, engines, turbines, exhaust systems, etc.

Explore the Possibilities with Simcenter 3D

How does Simcenter 3D help you explore the possibilities? With an open and scalable environment for different discipline specialists & design engineers and provide timely simulation data earlier in development process.

Compare the Influence of Different Durability Load Events

For durability simulations, there can be many load events to review. Manually clicking through each to find the most important can be quite time consuming.

A new dedicated post-processing scenario helps you more easily analyze the contribution for each event:

- At the most damaged position

- For all components/groups or for each individually

- At user-defined positions

- For all durability results (damage, lifetime, stress amplitudes, safety factors, and so on)

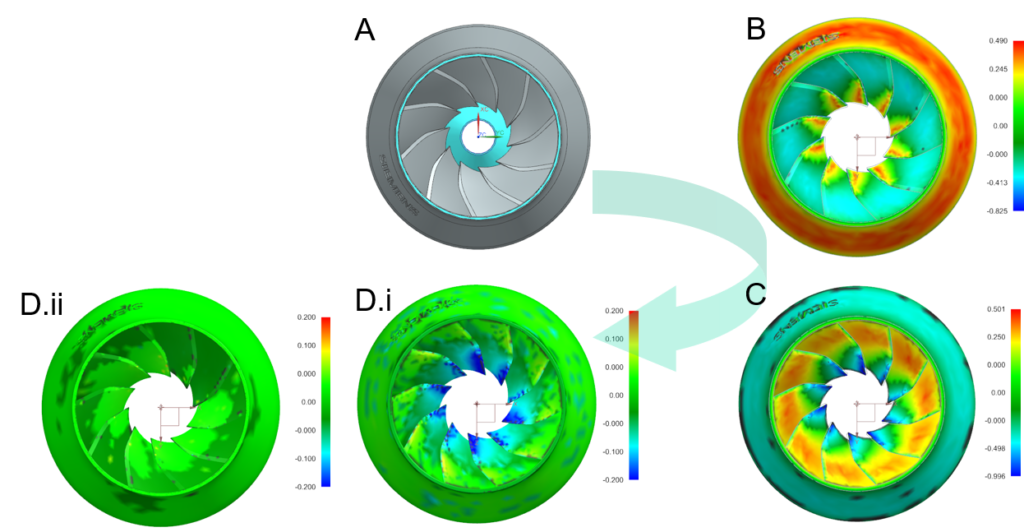

Improved Compensation Optimization for Additive Manufacturing

The heat created during the additive manufacturing process can deform the final shape of the printed part. This can result in a part that doesn’t meet geometry tolerances. To correct this, Simcenter 3D can create compensated CAD geometry based on the predicted deformed shape.

Stay Integrated with Simcenter 3D

As product development has become increasingly complex, there are more opportunities for misalignment between teams. Development in different functional areas happens simultaneously. Simcenter 3D provides the features and capabilities that help teams stay integrated across all relevant functions.

Simulate Aeroelasticity

Aeroelastic Simcenter Nastran solvers are supported in Simcenter 3D 2021.2. You can assess aircraft dynamic response on gust events in an isolated environment. Perform this dynamic analysis (pre- and post-processing) in a fully integrated and consistent platform, which also provides CAD associativity and data management out of the box.

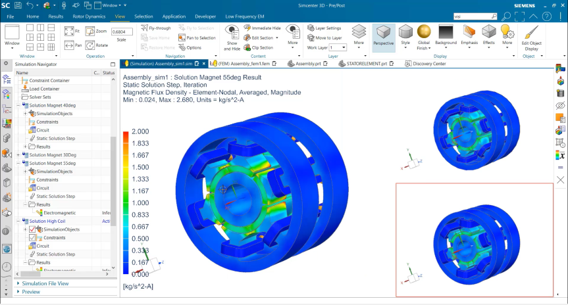

Tighter Integration for Low-Frequency Electromagnetics

Expanded post-processing capabilities for Low-Frequency Electromagnetics. 3D electromagnetic fields such as Current Density and Magnetic Flux Density, Forces and losses, can now be viewed and analyzed through the integrated post-processing capability of Simcenter 3D.

Want to know even more? Read these additional blogs on Simcenter 3D 2021.2

For more information on Simcenter 3D

- Simcenter 3D: Complete Guide

- Free Trial: Try Simcenter 3D online today for 30 days

- Visit Support Center to download Simcenter 3D 2021.2 or contact support

- New customer? Contact us to discuss further