Simulation-Driven Design – Carmakers Rely On CFD To Drive Aerodynamic & Engine Design

Some of the key highlights I found from the article echo the challenges we see customers facing and that NX addresses, these include:

- Complex and ever-increasing requirements (e.g. regulatory or customer-driven) that lead to large number of evaluation parameters for any given design. For Ford the solution is to use design of experiments (DOE) to evaluate the effects of these parameters on the vehicle and the system as a whole and optimize accordingly. (watch this space for more on this topic in the coming weeks!)

- Automotive customers needing tools to facilitate a faster simulation workflow rather than addressing niche physics problems.

- Virtual simulation facilitating the testing of more design iterations especially those that may never physically exist.

- Fluid mechanical challenges being multiphysics problems. CFD analysis cannot be done in isolation but instead requires a system-level and multi-disciplinary approach considering other physical domains such as mechanical stress or heat transfer

- How high-fidelity CFD is now possible with more computational power available addressing more complex problems such as turbulent, transient problems by taking advantage of parallel computing on multiple processors all the while remaining cost-effective.

The common theme here I see is complexity and being able to manage that complexity efficiently. All cars have for a long time performed their basic function well, transporting people from A to B, but for automakers to remain competitive they must offer differentiation, often to the point of making their cars uniquely tuned to each customer’s desires yet at the same time being universal.

As Ravi from our team states in the article all these desires form requirements and they often have to be balanced against other requirements such as regulatory or fuel efficiency standards. Indeed as this ad for the Chevrolet Cruze points out it’s “loved all over the world” yet assuredly the requirements in each of the 119 countries will be different.

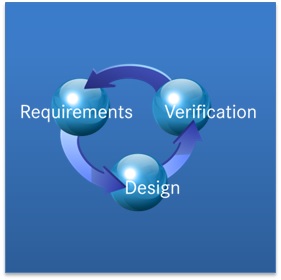

The implications for product development are how to funnel these requirements then into sound engineering decisions. By offering an integrated toolbox, Teamcenter, NX provide a seamless workflow that both translate these requirements into design & engineering parameters that are verified in an interative loop which then trickles down from system to sub-system to component level and are validated back up using NX Simulation at each level.

This is illustrated neatly in the V-diagram below. Another factor that adds to complexity is all these steps are done in parallel with other disciplines, thus in this case a fluid flow problem is actually a multi-physics problem with thermal & structural implications as well.

NX Thermal/Flow DMP (Distributed Memory Parallel) addresses the last challenge – high-fidelity CFD – by leveraging multiple processor hardware (desktops or clusters) by providing a parallel flow solver and using domain decomposition techniques to “break down” large computational models into smaller pieces that can be handled on each processor. Just as important, a DMP license can spawn a solve over as many processors as are available at no additional cost ensuring the only limit is the number of available processors at any one time.

One last point in the article is the added benefit of simulation-driven design as seen by Rod Baker from GM’s Advanced Engine Design group. CAD-CAE integration is getting tools in hands of product designers enabling rapid iteration of designs without dealing with the bottleneck of the limited time resources of an analyst; analysts are integral of course but can now focus on analyzing more complex challenges and creating templates that guide and automate tasks for designers that they otherwise used to do.

In the future I will revisit this topic, but how about for you, in your organization or industry? As an analyst do you see simulation driving the design, being the critical linchpin in the product development process? Let me know in the comments below!