Achieve simulation-driven design faster with integrated 1D and 3D simulation

Simulation-driven design solves problems many engineers face in the automotive industry today. Vehicle complexity grows exponentially with consumer demand and government regulation for more fuel efficient vehicles. Add to that manufacturers who seek to develop more innovative powertrains, and you can start to see how things get even more complicated. We’ve previously discussed how simulation-driven design simplifies the vehicle engineering process.

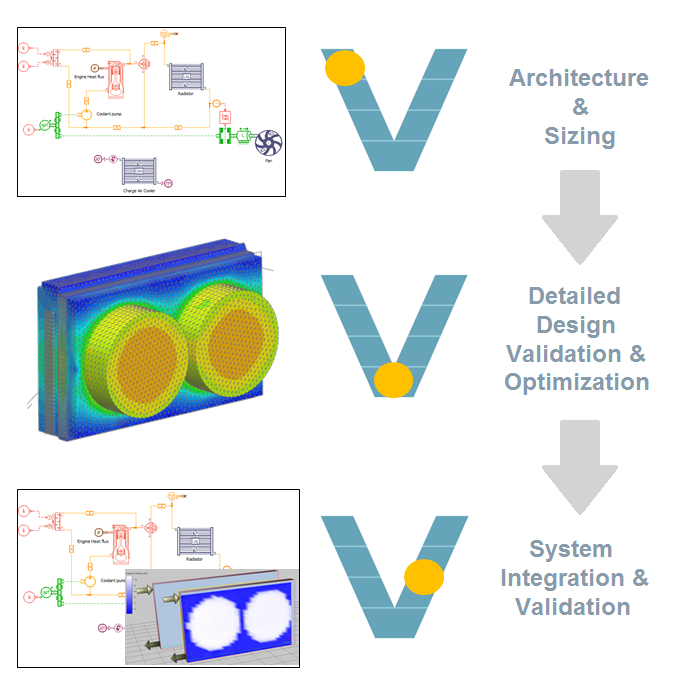

To tackle the challenges laid out above requires a systems engineering approach to achieve new vehicle innovations. Engineering teams are increasingly moving more towards a model-based systems engineering (MBSE) method. Siemens PLM can help manufacturers achieve this through model-based simulation and validation through the integration of 1D and 3D simulation. My colleague Patrick Farrell explained this process in his presentation “Model-Based Multi-Discipline Development Using 1-D and 3-D Simulation” at the 2014 NAFEMS Americas Conference that took place in Colorado a few weeks ago.

“By combining Simcenter’ and Siemens PLM’s CAE software portfolios, we are now able to integrate simulation and validation throughout the entire systems engineering process, from concept to detailed design, to physical testing. This will allow engineers to rapidly evaluate and validate new concepts faster than ever before,” he said.

used to quickly determine if the cooling system will be sufficient and determine which areas of the system might need further changes. Using this information, he showed how engineers can rapidly propose, simulate, and validate detailed design changes to a 3D model of a radiator to achieve target performance. Then to close the loop, he demonstrated how 3D simulation results can be used to improve accuracy of future 1D simulations. As you model and validate at each step in the process, you guarantee reliability in your product’s end performance.

This topic exemplifies “Driving Product Development with Collaboration, Simulation, and Integration”—the theme for this year’s NAFEMS conference.

Pat was just one of three speakers from Siemens PLM who presented to roughly 150 people at the three-day conference. Other Siemens PLM attendees included Ben-Shan Liao who presented “High Performance Modal Analysis on Hybrid CPU-GPU Systems,” and Karthik Balachandran who discussed “Advanced Simulation Technologies for Electric Motor Noise Predictions.”

Did you have a chance to catch one of our presentations at NAFEMS 2014? If so, tell us about it in the comments below. Even if you didn’t, we want to hear what you think! What are your thoughts on using 1D and 3D together to drive results with model-based simulation and validation?

Amy