The TUMULT Project: Ensuring Quiet Travel

Flying has come a long way since the Wright brothers first took to the sky. Planes now feature Wi-Fi for those looking to surf the web, or seat back screens for anyone looking to binge watch their favorite show. However, if there’s one thing that seems to give passengers cabin fever: it’s noise. After all, nobody likes obnoxious noise pollution, let alone on a cramped eight-hour flight. The real question is: What can be done about this?

A major source of noise during flight is caused by the turbulent boundary layer (TBL) that develops on fuselage structures on aircrafts. Knowing this would impact customer experience, aircraft developers must predict interior cabin noise during the early stages of aircraft design. Traditionally, an engineer would perform a costly high-fidelity CFD simulation to optimize the transfer path of the noise. However, another, more affordable, alternative is to use semi-empirical models to approximate the TBL excitation.

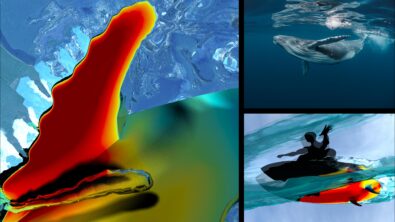

The TUMULT (“TUrbulent flow noise Modeling for Under- and upperbody Load and Transmission analysis”) project is a 3-year project that addresses noise and vibration issues that arise during turbulent flow in transport vehicles (cars, trains, aircrafts, ships, submarines). The goal is to develop both innovative simulations and test methods for analyzing/modelling aeroacoustics noise sources and their transmission to interior compartments. TUMULT does this by calculating the TBL wall-pressure loads using semi-empirical models based on mean flow parameters. These flow parameters are obtained through analytical relations of either experimental data or numerically from CFD. Thanks to the TUMULT project, Siemens has an efficient solution based on semi-empirical models for TBL simulation, and it is now available as part of the Simcenter 3D Acoustics 2019.1 release.

In the TUMULT project, the performance of the TBL method has been demonstrated for an academic case: a flow-excited flat panel connected to an acoustic cavity, as shown in Figure 1, in which the results are compared to experimental results [1].

Figure 1: Validation of the TBL loading method for interior cabin noise prediction. Top left: the model, composed of a flat plate and an acoustic cavity. Top right: the TBL loads from semi-empirical models. Left Bottom: the acceleration PSD results from Simcenter 3D at the center of the plate (red) compared with the experimental results from the literature [1] (blue). Right Bottom: Acceleration (on the plate) and acoustic pressure propagating in the cavity.Since then, it has been shown that the TBL loads can be applied to industrial-sized cases. An aircraft panel and aircraft cabin model combination are shown in Figure 2, including absorbing materials such as roof, carpet and seats. First, the TBL loads are computed for a selected cruise condition. Then, the impact on the vibro-acoustic response at selected passenger positions is calculated.

Figure 1: Validation of the TBL loading method for interior cabin noise prediction. Top left: the model, composed of a flat plate and an acoustic cavity. Top right: the TBL loads from semi-empirical models. Left Bottom: the acceleration PSD results from Simcenter 3D at the center of the plate (red) compared with the experimental results from the literature [1] (blue). Right Bottom: Acceleration (on the plate) and acoustic pressure propagating in the cavity.Since then, it has been shown that the TBL loads can be applied to industrial-sized cases. An aircraft panel and aircraft cabin model combination are shown in Figure 2, including absorbing materials such as roof, carpet and seats. First, the TBL loads are computed for a selected cruise condition. Then, the impact on the vibro-acoustic response at selected passenger positions is calculated.

Figure 2: Aircraft cabin noise case – a panel with TBL loads that has an impact on the cabin noise.

Figure 2: Aircraft cabin noise case – a panel with TBL loads that has an impact on the cabin noise.

Furthermore, Figure 3 shows that because of the TBL noise from the selected panel, the passenger sitting near the panel does experience a higher noise level as compared to a passenger sitting further away. Each passenger experiences a superposition of noise originating from all the panels of the fuselage, and the presented modelling methodology helps to efficiently gain insight on the main contributing panels. In the next step, the design of the panels and the transfer paths to the passengers can be modified and optimized. The TBL load models can be coupled with the high-order FEM solver (FEMAO) for efficient FEM-based vibro-acoustics predictions, see also the previous blogpost on FEMAO.

Figure 3: Aircraft cabin noise case: on the left, the locations of passenger 25A (red) and 26D (blue); on the right, the acoustic pressure response in the cabin at the positions of passenger 25A (red) and 26D (right), resulting from the TBL loads shown in figure 2.

Figure 3: Aircraft cabin noise case: on the left, the locations of passenger 25A (red) and 26D (blue); on the right, the acoustic pressure response in the cabin at the positions of passenger 25A (red) and 26D (right), resulting from the TBL loads shown in figure 2.

Reference:

- C. Heatwole, R. Bernhard, M. Franchek, “Robust feedback control of flow induced structural radiation of sound”, NASA report Report #0278-1, 1997.