Improving existing technology to meet shipping emissions targets

“This is a very important signal for the shipping industry and the maritime cluster to work full steam ahead to reduce greenhouse gas emissions” said Panos Laskaridis, president of ECSA, The European Community Shipowners’ Association.

Panos Laskaridis was speaking after the IMO Marine Environment Protection Committee (MEPC) announcement in April 2018: member state delegates have agreed on a target to cut the shipping sector’s overall CO2 output by 50 percent by 2050, aiming to begin reductions as soon as possible and pursue efforts to phase out carbon emissions entirely. This IMO announcement comes as an additional measure to strengthen the Energy Efficiency Design Index (EEDI) efficiency requirements already mandated for new ships. [ref.1: IMO Agrees to CO2 Emissions Target published in Marine Executive, April 2018: https://www.maritime-executive.com/article/imo-agrees-to-co2-emissions-target]

Shipyards now have no choice but to introduce new vessels which fit with these emission limit requirements. In addition to this environmental regulation, they also must respond to another expectation – coming from the market and fleet operators – that the less fuel the ship consumes (and therefore the less CO2 emitted) the lower the operational expenditure will be.

Improving existing technologies is one obvious way to reach these targets. Focusing on the marine engine design and even on components of one system can be a way to fit with requirements. However, the development time is always constrained as to keep being competitive the shipyards have to introduce new technologies quickly to the market. In a fast-paced design environment, using simulation to analyze the efficiency of a product at an early stage of the design cycle can make a significant difference to development times.

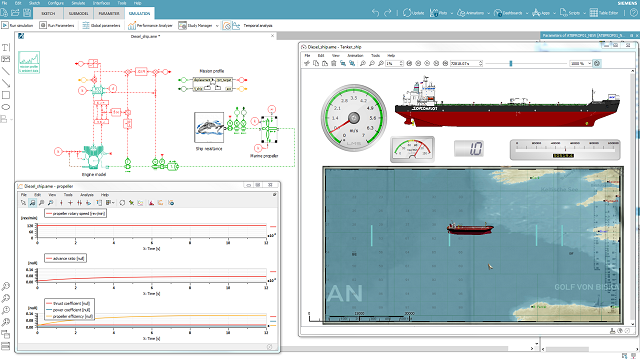

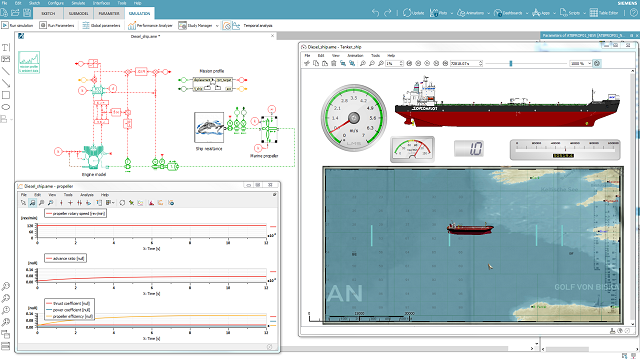

That’s why Ganser Common Rail Systems (CRS) decided to opt for system simulation to develop and analyze an improved control hydraulic valve (the poppet valve) to reduce engine emissions of a vessel. Simcenter Amesim for marine propulsion systems

Simcenter Amesim for marine propulsion systems

Application case: Ganser CRS chose to use Simcenter Amesim, the system simulation solution which is part of the Simcenter Portfolio, to improve the control (poppet valve) valve design to reach the very small injection quantities used in micro pilot applications. Using Simcenter Amesim, the Ganser CRS engineering team improved the nozzle needle geometry through validating and implementing two new features:

The new technology developed by Ganser CRS was tested on a marine engine, replacing the previous mechanical injection system. New Ganser CRS systems are employing not only this unique poppet valve technology, but also a Waves Dynamics and Dampening System (WDD) and injector integrated accumulators. The final achievements on the 6-cylinder dual fuel marine engine, without any modification of the cylinder head, are impressive. Tests proved a stable operation of the engine in gas mode with gas ignited by diesel and the achievement of IMO Tier 3 emission levels. More details can be found in the published paper.[ref.2 Common Rail Injectors With Poppet Valve by Ganser CRS published in Diesel&Gas Turbine Worldwide, September 2016 https://dieselgasturbine.com/common-rail-injectors-poppet-valve/] |

While this example shows how simulation can help to improve existing engine designs, some shipyards are eager to go one step further in the design of their vessel andstep directly into the hybridization of their machine, again using system simulation. Curious to know more about how it can be deployed? Read Vessel hybridization, too ambitious you said?

More info

Visit our webpage Simcenter Amesim for propulsion system

Watch the video Simcenter for Marine video