Improve your system simulation efficiency with Simcenter Amesim

Focus on what really matters – engineering

In our professional life, when encountering the need to perform simulation tasks, often the first reflex is to use the tools we were using during our university studies. But unfortunately, by doing so, a lot of time is spent to build models, define equations, find the right solvers, tune the models, etc. The time…. we had available, as students.

But as employees, we don’t have this time to “program and trial and error”. We should be spending our time on designing, engineering, improving and innovating products. We should not lose our time on programming or trying to develop our own tools as this brings no added engineering value. And even more, this approach brings a lot of risks and problems: developing own programs is error-prone. It makes your processes dependent on persons. If these employees leave the company, the knowledge of how the models/tools have been developed also leaves. As a consequence, the whole task/work gets stopped, and people are in serious problems.

From early concept design, let simulation drive your development

Today, there are professional tools on the market, like Simcenter Amesim, that can perform these simulation tasks without any programming, by using thousands of validated components, allowing you to maximize time spent on engineering.

In this video below, you can see how Simcenter Amesim can support the complete design V-cycle.

Build your simulation model in 2 days instead of 3 months

Recently, I have met a company designing transmissions spending 3 months on developing models to represent their transmission. But after all this time the models were lacking sophistication, didn’t take into account thermal effects and did not have sufficient loading conditions. The models were difficult to change, and last but not least, it was difficult to run what-if scenarios…

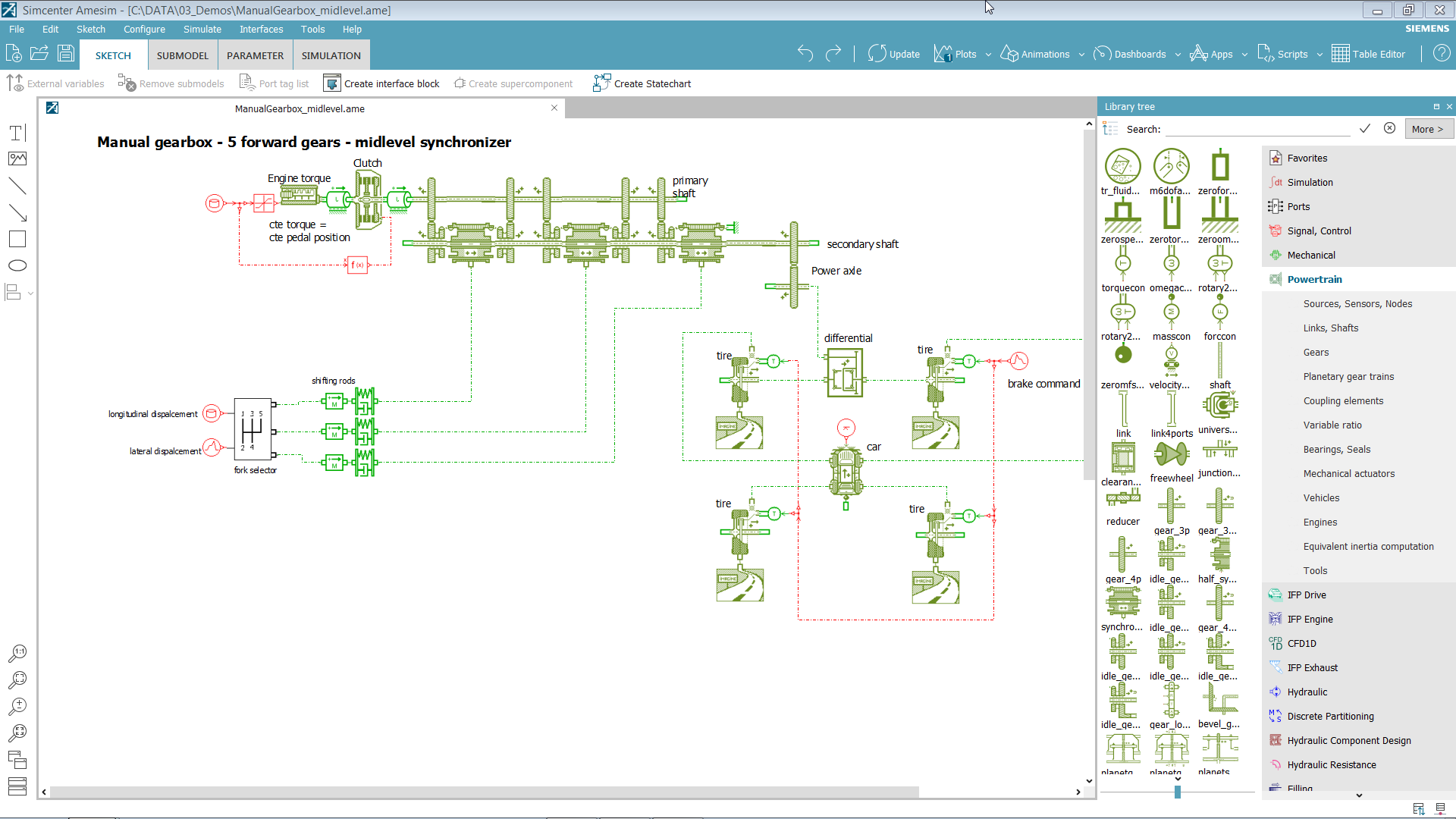

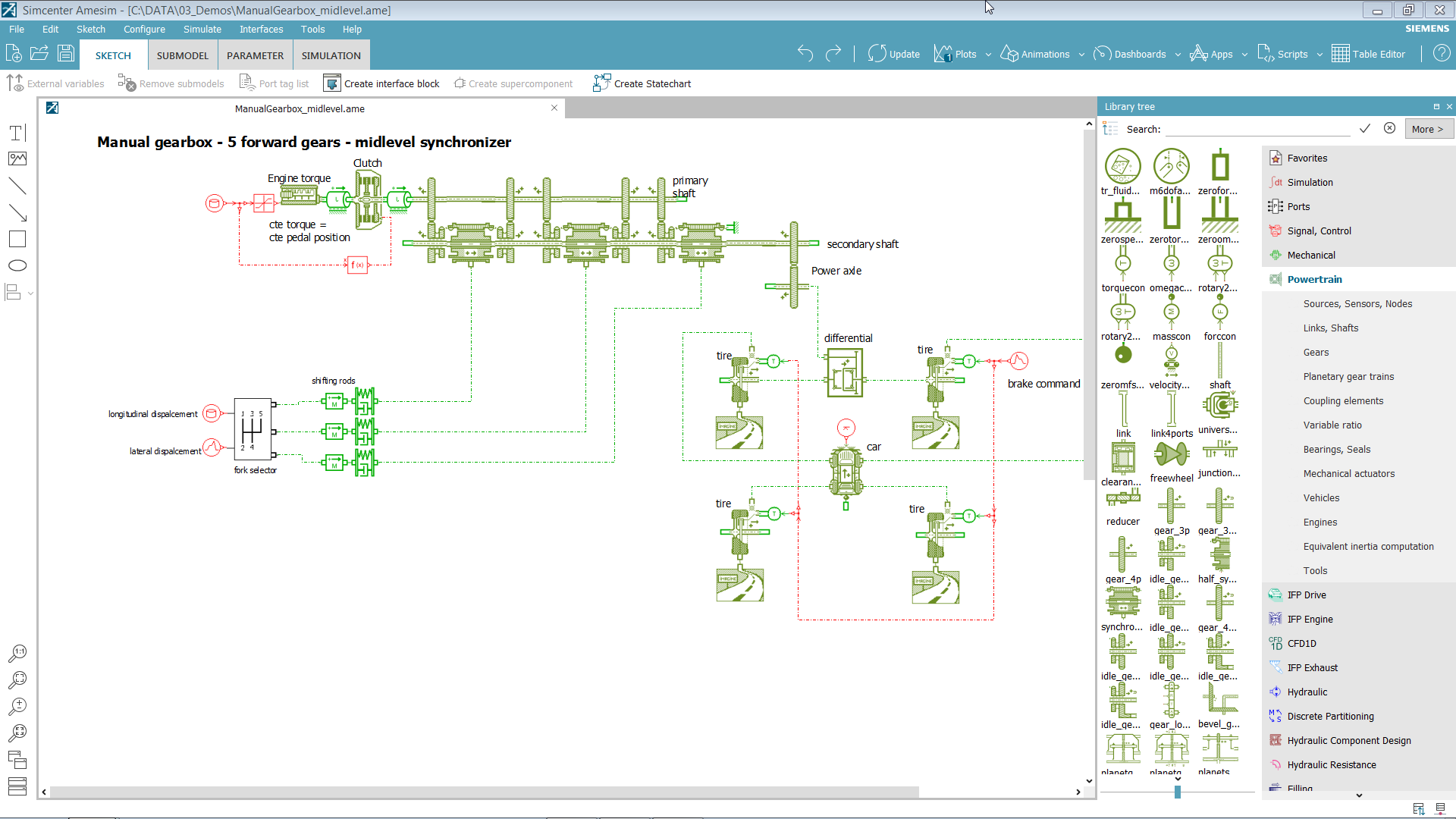

Then, this company created a model of the same transmission in Simcenter Amesim. They were able to do so in 2 days, after only 2 days of training. This model was easy to modify and allowed them to efficiently perform trade-off studies, – which is why the model had been built.

As an example, with Simcenter Amesim, you can easily model the entire transmission, including all actuators and controllers, and evaluate their interactions during the powertrain and driveline integration in the chassis. You can reproduce all physical phenomena in order to optimize your design, and in this way shorten the calibration phase. Without any programming.

Simcenter Amesim also performs Design of Experiments (DOE), optimization and robustness studies, and can be directly coupled to other codes like Simcenter HEEDS. Simcenter Amesim delivers a high ROI, by providing an industrial system simulation solution, containing more than 6500 validated elements across multi-physics and across industries, deep analysis, automation and optimization capabilities. On top of this, Simcenter Amesim is an open environment that tightly connects to the whole Simcenter portfolio, and to all other major CAE, CFD codes.

Streamline controls development and validation

Often engineers use MATLAB Simulink to develop control logics, and then they also use it to develop the model that represents the physical system; so then control logics can be tested (MiL-SiL-HiL) with a (virtual) representation of the product. But this means that control development people have to create a model representing the product. This model typically is less detailed and accurate but allows users to also run in real-time.

This approach can bring a lot of challenges: first of all, this requires a double modeling effort, next to this there is the challenge to keep the control validation model aligned with any changes in the real physical model (product design changes), and last but not least, this validation model is less accurate which impacts validation of control code.

The combination of MATLAB Simulink for controls development and Simcenter Amesim for multi-physics system simulation removes all these challenges, by allowing you to export from the multi-physics product model to a coarser model that can be used for controls validation. Simcenter Amesim determines the model extraction based on the requirements set by the user (real-time step, …). This way you always use maximum accuracy and you stay always aligned with the product. With no extra effort, the validation of controls can be performed, like in the General Motors video below: