(Part 2 of 2) A&D and Operational Excellence: Myths versus Reality

In Part 1 of this blog series, I described the concept of Operational Excellence, key metrics, and the challenges to achieving Operational Excellence that are unique for the A&D industry. In this blog, I am focusing on what I’ve seen as the best approaches by leading A&D companies that are charting their path towards true Operational Excellence. Then I will describe some of the misconceptions I see from manufacturers considering a digital enterprise approach.

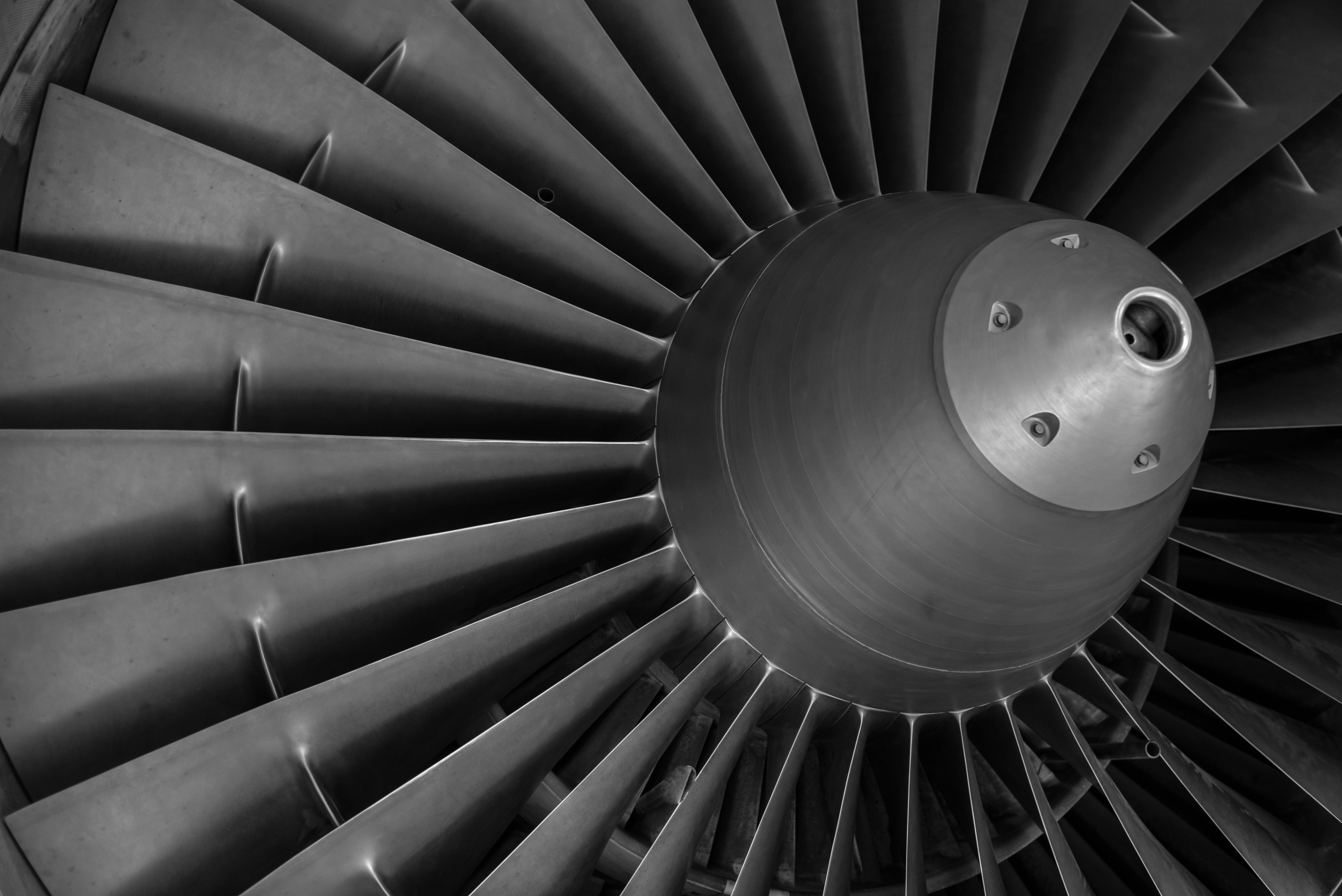

So, what are the “best-of-the-best” A&D manufacturers doing? I see a common theme. They are embracing new technologies, and embarking on the digitalization journey. No matter how far they have gone, or if they are just starting, they are adopting the digitalization of value streams, a process chain from customer requirements, to engineering design, to the manufacturability studies and manufacturing process assessments, then getting into actual manufacturing. To streamline those processes, they are looking at PLM/MOM/ERP systems as a holistic system, creating a “digital thread” across those systems that is enabling the integration of the manufacturing systems infrastructure.

Most have not fully reached this state, but they are looking at this type of approach. They are considering how they can improve their operational side, and what the implications are for changes to the engineering side as well. The big leaders have started to create plans for their digital transformation journey in a holistic approach. Still, production or shop-floor in many cases is looked at in isolation, which hinders the required digital transformation.

So, why don’t all A&D manufacturers have their digital transformation journey mapped out? Let me get into what I call the “myths vs. reality” for A&D.

Myth #1: Our current processes and cross-department collaboration is working but lacks discipline.

The reality here is that there is a systematic failure that is preventing collaboration, regardless of how dedicated the people are. Disparate, disconnected, point solutions across the shop floor make information sharing difficult. Collaboration tools among teams are either non-existent, or cumbersome at best. What I see is that engineering and manufacturing teams recognize the need to collaborate, they simply don’t have the systems and tools in place to make it easy along with required discipline.

Myth #2: Our shop-floor and “niche” point solutions are good enough to achieve Operational Excellence

The reality is that advanced manufacturing technologies need richer data from engineering systems, which should be flowing to new automation systems, and which can only be achieved through the right level of business-process-oriented collaboration. The increased customizations in engineering and/or business systems drives rapid change into manufacturing, which must be connected to handle efficiently into niche solutions. Incorporation of engineering and/or manufacturing changes is a tedious process. To get to the efficiency required for Operational Excellence, a connected infrastructure with a holistic manufacturing operations backbone is required.

Myth #3: Our shop-floor infrastructure is archaic and we cannot collect required data from machines or people in the right way

The reality is that sensors and advanced technologies can make machines smart. You can collect data even from legacy machines, producing data that can and should be incorporated into the manufacturing lifecycle to improve efficiencies and drive effectiveness, allowing you to understand root cause and feed data back into engineering. Gathering data at the point of use can enable timely human and machine data collection adhering to process requirements. Automation of the human-machine data collection at point of production is key for agility.

Myth #4: We collect all sorts of data, all we need is a data warehouse and analytics tool

The reality is that there is complexity and data redundancy that is not taken away for educated decision making by simply loading raw data into a warehouse for analysis by a tool. You must couple process improvement tools with the data to achieve flexibility and effectiveness. This requires a blend of IT and OT for streamlined process improvements.

If you are considering your digital transformation journey, here’s what I would recommend. Given A&D manufacturers are typically heavily invested in ERP and PLM systems, look first at how to synchronize those systems with harmonized shop floor systems. As you consider investment in automation, robots, and mobile, keep the shop floor systems harmonization in mind as well. The orchestration of manufacturing across all of these areas is what drives true Operational Excellence, and will create the true ROI across new investments. You must have a feedback loop and holistic approach to production intelligence to avoid mistakes, build a knowledge base for subsequent design improvements, and accelerate production to meet customer requirements.