Five Practices PCB Designers Should Avoid

PCB design and manufacturing are complex processes that affect the PCB’s functionality, manufacturability, quality and cost—all important aspects necessary to commercialize the PCB. There are five common practices that designers use in this process that should be avoided to make the design and manufacturing of the PCB leaner.

1. Not involving the vendor early

When designing a PCB, you need to involve your PCB vendor as early as possible because the design should be analyzed for manufacturability, and the results could significantly affect the PCB’s cost and time to market. It is best to find the manufacturability issues (e.g., poor documentation, missing data and spacing between components, etc.) as soon as you can—because the sooner you find these issues, the easier and the cheaper it would be to resolve them.

2. Putting non-copper features on copper layers, without considering the impact on manufacturing

Sometimes non-copper features are used on the copper layers because it helps the designer to find out if a feature gets too close to a copper layer; however, this practice jeopardizes the quality of the board as it can cause confusion downstream. When the design is handed-off to manufacturing, these non-copper features might be misinterpreted and mistakenly treated as copper features in the manufacturing stage. This kind of mistake might cause functionality and quality issues that leads to scrapping the manufactured PCBs.

To avoid such issues, put only copper features on the copper layer and use the appropriate layers for the other features. Although it might be less convenient for the PCB designer, it would make the manufacturer’s work much easier and allow manufacturing the PCB faster and with better quality.

Additional design issues are addressed in our latest white paper – download it now.

3. Sending Gerber files to manufacturers when the manufacturers will have to restore information that is “lost in transition” because of the format limitations

Gerber files have been widely used in the industry for decades, and many PCBs are manufactured based on designs that are carried on this format. However, manufacturers can have difficulty interpreting this format, requiring them to perform tedious reverse engineering to properly reflect the design in their manufacturing environment [1]. This labor-intensive work is prone to errors and requires a lot of time and resources from the manufacturer to import it to their manufacturing system.

Instead, designs can be exported in ODB++Design format to avoid this unnecessary work and misinterpretation risk at the manufacturing side. This format includes all the design information, and it is easy for the manufacturer to interpret and use this format.

4. Not ensuring that the silkscreen has sufficient distance clearances for solder masks

A PCB is typically composed of highly dense components. Each of these components has its own contact points to the board, and these contact points must be clear to allow conductivity between the board and its assembled components. Silkscreen is a non-conductive ink that is used to mark all the components’ locations and annotations on the PCB. In case the silkscreen is not sufficiently distant from solder paste clearances, it might affect the conductivity and may result in a quality issue that results in rework or scrap.

To avoid such issues, make sure that the silkscreen is distant from solder mask clearances. This job gets harder as the PCB gets denser. To ensure the silkscreen causes no quality issues, use an automated DFM tool that takes into consideration the manufacturer specific technology and capabilities. This would ensure that silkscreen causes no issues and that the PCB is manufactured with the proper quality.

5. Tweaking the board for fabrication and unintentionally affecting functionality.

When the PCB design gets to fabrication, often the design is “tweaked” to reduce production cost and make the production faster. In most cases, these tweaks do not affect the board’s functionality and the board works as designed. However, in some cases, the fabricator unknowingly makes a change that alters the board’s functionality, resulting in a board that does not meet the designer’s criteria. This is a costly mistake, and it harms the fabricator’s reputation because the supplied order is useless for the designer who ordered the boards.

To avoid such mistakes, the fabricator needs to have a tool that allows communicating all the design issues and the proposed changes to the board early in the design-for-manufacturing stage.

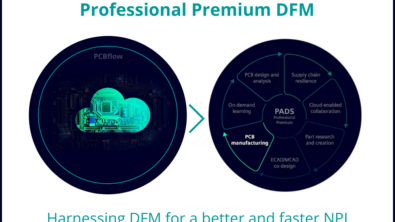

PCBflow as a means to avoid these mistakes

PCBflow is Siemens’ online design-for-manufacturing tool and collaboration space for PCB designers and manufacturers. This tool allows designers and fabricators to share the PCB design in ODB++Design format, identify design for manufacturability issues early in the process, communicate changes to the design and be completely sure that the manufactured PCB answers all the designer’s requirements.

To learn more and sign up, visit PCBflow now>>

Additional PCB design issues are addresses in our latest white paper – download it now.