How ANGER MACHINING utilizes 3D process simulation with NX CAM

Based in Austria, ANGER MACHINING specializes in the development and production of Transfer Centers for the machining of serial components with especially high precision requirements for the automotive industry and related metalworking companies.

Challenges

ANGER was challenged by market demand for increased productivity, customer demand for more flexibility and elevated precision requirements.

Solutions

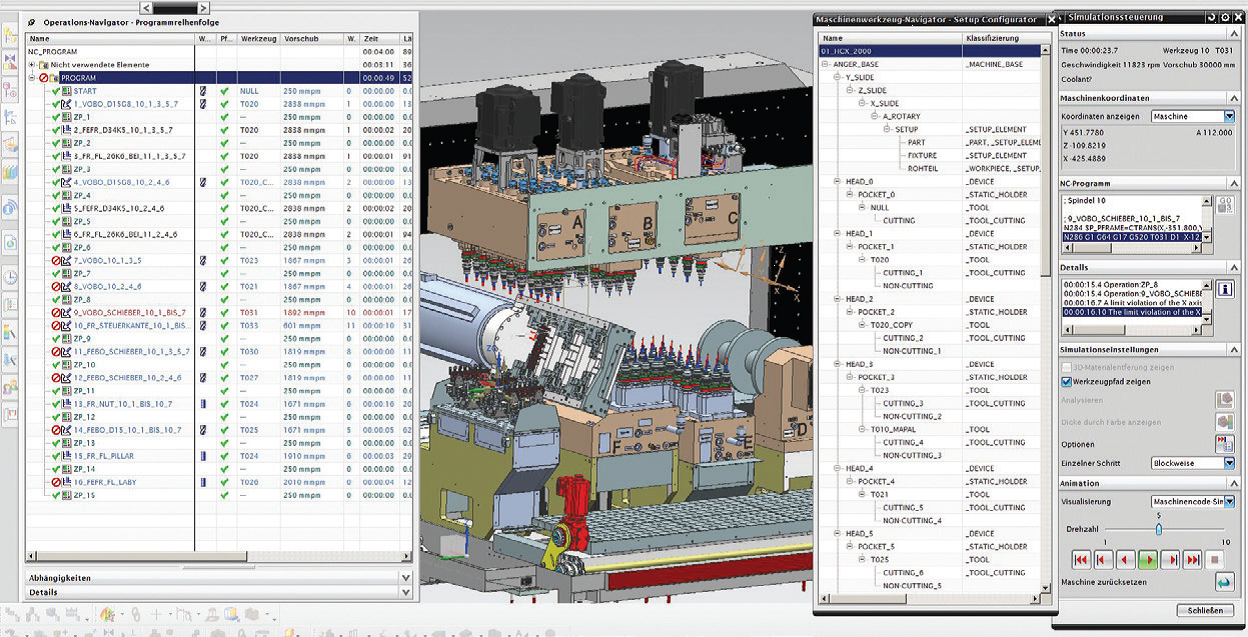

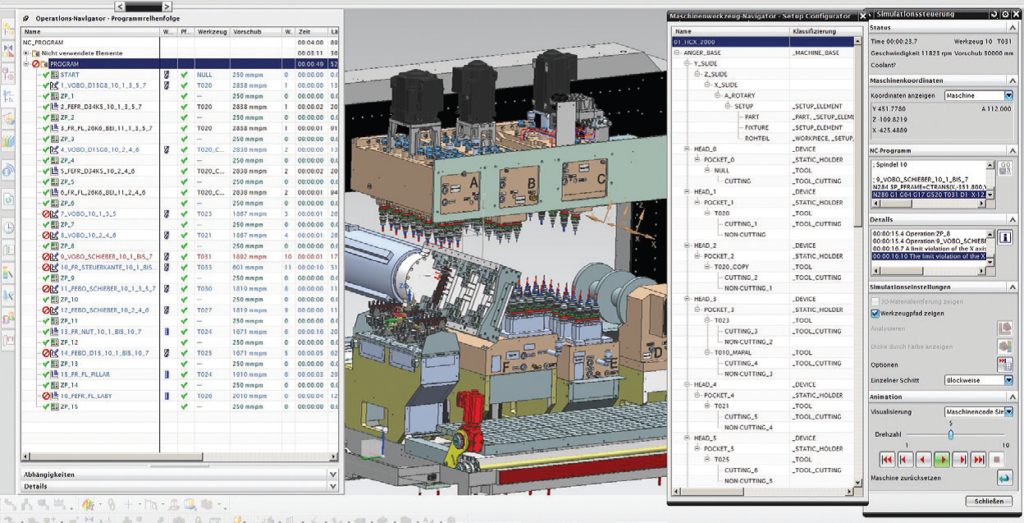

Siemens’ NX is used both for process engineering and for programming the machine tools on the shop floor. With comprehensive simulation of the production process, users can develop efficient

manufacturing processes and generate optimized numerical control (NC) programs with automated collision detection.

To master the high level of complexity, ANGER machines are equipped with Siemens SINUMERIK 840D sl computer numeric controls and SIMOTION drive technology, the programs which are generated using Siemens’ NX CAM software. This assures full data consistency from the design to each single axis.

Using the 3D design model as an input, Siemens’ NX CAM software enables ANGER’s engineers to quickly generate NC programs to effectively machine parts. Error-free machining on the shop floor is enabled by the integrated machine tool simulation using NX CAM software.

Results

ANGER offers its customers improved efficiency and process reliability and are able to significantly improve their competitiveness with comprehensive simulation of the machining processes based on NX CAM software. They are now able to reduce engineering cycles by thirty percent, lower design costs by twenty percent, and they have achieved 100 percent collision freedom.

Integration of the 3D design model and consistent workflow management provide an optimal basis for decision making as well as fast planning and calculation results for both products and processes. In the

HCX series, ANGER used comprehensive machine tool simulation to cut design costs by 20 percent and improve average lead times for a contract by 30 percent.

The advanced machine tool simulation in NX CAM is critical to reliable NC programming of the ANGER FLXBL machines that use innovative technology for changeover and tool change. To master the high level of complexity, the machines are equipped with Siemens’ SINUMERIK 840D sl controllers and SIMOTION drive technology. The Siemens software and equipment assures full data consistency from the design to each single axis.

Markus Schürz, design engineer at ANGER Machining

With comprehensive simulation of the machining processes using NX CAM software, ANGER offers its customers improved efficiency and process reliability. With NX CAM, they were able to significantly improve their competitiveness.

Read the complete ANGER ENGINEERING case study and let us know what you think in the comment section below.

Check out Siemens’ Manufacturing 360 tablet app!

Explore the world of digital manufacturing. See how Siemens’ software

for part and assembly manufacturing enable more efficient and nimble operations.

Download the FREE Manufacturing 360 app from Google Play or the Apple Store.