Additive & Hybrid Manufacturing: The Future of 3D Printing is Manufacturing — by Andreas Saar

During the presentation, “Additive & Hybrid Manufacturing: The Future of 3D Printing,” I described how hybrid additive manufacturing can revolutionize industries, by changing the entire creation process of products from the idea to the finished product.

A Transformative Technology

I believe that additive manufacturing will liberate engineering creativity, unleash new capabilities, and enable the development of innovative products faster. The technology will be a game changer as it increases design innovation, improves performance, reduce production costs and speeds up time to market.

The 3D printing market is projected to experience double digit growth in the next 5+ years. 2014 alone had a 31 percent increase. The aerospace and defense industry has been an early adaptor of the additive manufacturing and they have 14% share in the additive manufacturing. The housing for a temperature sensor recently became the first 3D-printed part certified by Federal Aviation Administration (FAA) to fly inside GE commercial jet engines.

What this means is that printers will get cheaper as more manufacturers enter this market and the performance will be improving dramatically. In the plastics area, we are hearing about developments that increase the printing speed by factor 100+ and with multiple lasers additive manufacturing in metal will gain speed too.

Introduce More Innovative Products

Typically costs go up with complexity – with additive you can implement more advanced features which improve the performance of your product for less or the same money.

As you can see with this motor casting example – reduce weight with introduction of lattice structures and in parallel increase cooling surface.

Solutions to Current Challenges

Today the 3D Printing environment is largely an unmanaged environment. Data have to be exported from CAD – files are unmanaged. They are manageable in a Prototype environment, but not in production. There is also a problem with unauthorized duplication – Digital Rights Management. And there is little influence on the 3D printing process – OK for prototype, but not for production. The results are 50 percent of initial designs are unprintable, 30 percent need complete rework, and there are 3+ independent software systems in use.

The solution that Siemens supports is a complete 3D printing process as part of the Product Lifecycle Management.

- Files have secure Digital Rights mechanism embedded

- Printer files can be managed and accessed via Teamcenter (shop floor)

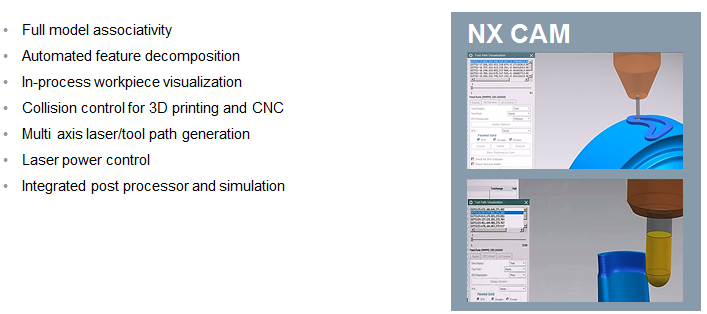

- NX for design, analysis, printer path generation and simulation in one system

- Feedback loop between every step of the process

- Feedback loops are essential to optimize the product performance

Hybrid Manufacturing: Additive and CNC Machining in One System

Hybrid manufacturing combines additive and CNC machining in a single environment. Currently, a typical manufacturing workflow to manufacture production-ready parts using additive involves combining the additive and CNC (subtractive) machining. It includes two processes, two file formats, two programs, and two set-ups – all need to be aligned in order to get to a finished part.

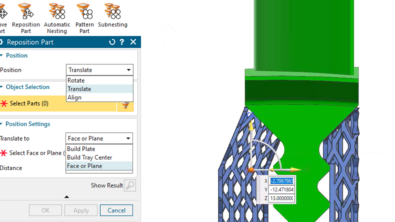

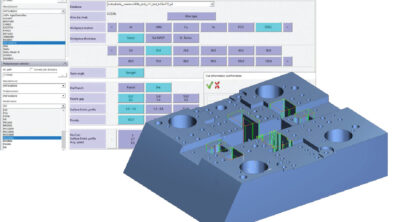

Hybrid manufacturing integrates additive and CNC machining in one system, which optimizes the entire manufacturing process:

The New Solution

I, and a representative from DMG MORI, introduced a strategic partnership in the development of the first production ready, industrial hybrid manufacturing solution on the market.

This new solution can be used for a wide range of industry applications:

Examples: Additive Manufacturing with LASERTEC 65 3D

Solution: An Integrated System

Siemens PLM Software NX CAM provides an integrated solution for programming, validation and post processing for hybrid manufacturing. The key hardware and software components of the new solutions.

To learn more about NX Hybrid Additive Manufacturing solution, please visit our website.