How simulation has helped fight COVID-19

COVID-19 turned the world upside down. Schools and restaurants closed. People were out of their jobs. Hospitals were overrun. Lives were lost. It seemed like the world shut down. But in reality, health care workers stepped up to take care of the ill and risked their wellbeing. Medical device and pharmaceutical companies started to race to find a cure for COVID-19. And other companies adapted to create products that would help save lives. Read on to learn about how companies used simulation to fight the pandemic.

Simulation in a medical evacuation cabin

To minimize the spread of infection, it is important to understand the risk of COVID-19 transmission in enclosed areas. The United States Air Force (USAF) set out to do just that. A medevac cabin was developed with a transient multiphase mode that has more than 100,000 particles to track the spread using a high-performance computing cluster. The model tracked particles and predicted the landing spots of these particles, along with the number of particles in the air.

This model influenced choices about cabin layout, patient density and airflow conditions. By using Simcenter STAR-CCM+, USAF was able to model the movement of contaminants from a sick passenger to optimize ventilation and safety procedures.

To read the full story, head to our customer’s success stories here.

Acceleration of UV-C air purifier development

When the pandemic hit, the world shut down, and questions were raised. How do we minimize transmission in indoor spaces? How can we reopen safely? Outdoor seating has become the norm as we live through the pandemic. People have taken to hiking and walking outdoors as a means to keep occupied. Indoors is the most dangerous place to be with COVID-19.

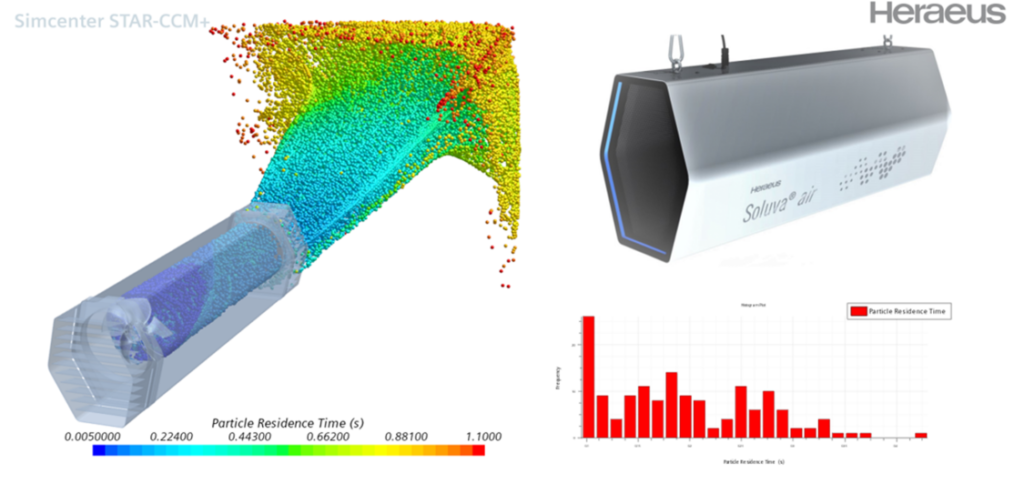

While the health care industry fights COVID-19 on the frontlines, other companies have turned their attention to another challenge – how to make indoors safer. Heraeus Noblelight is a leader in the light technology field, producing lamps with ultraviolet (UV) and infrared wavelengths. Following the onset of COVID-19, the company’s goal was to create a UV air purifier for killing the virus in the air. The project went from ideation to completion in only six months, and the Soluva UV-C lamp was created. To achieve their goal, Heraeus Noblelight used multiphysics CFD simulation with Simcenter STAR-CCM+ to optimize the device’s performance and analyze airflow and transmission of droplets. The team also used computer-aided design (CAD)-embedded Simcenter FLOEFD for optimal device placement inside a bus.

To learn more about the Soluva UV-C lamp, check out the full story here.

Classroom simulation for airflow and ventilation

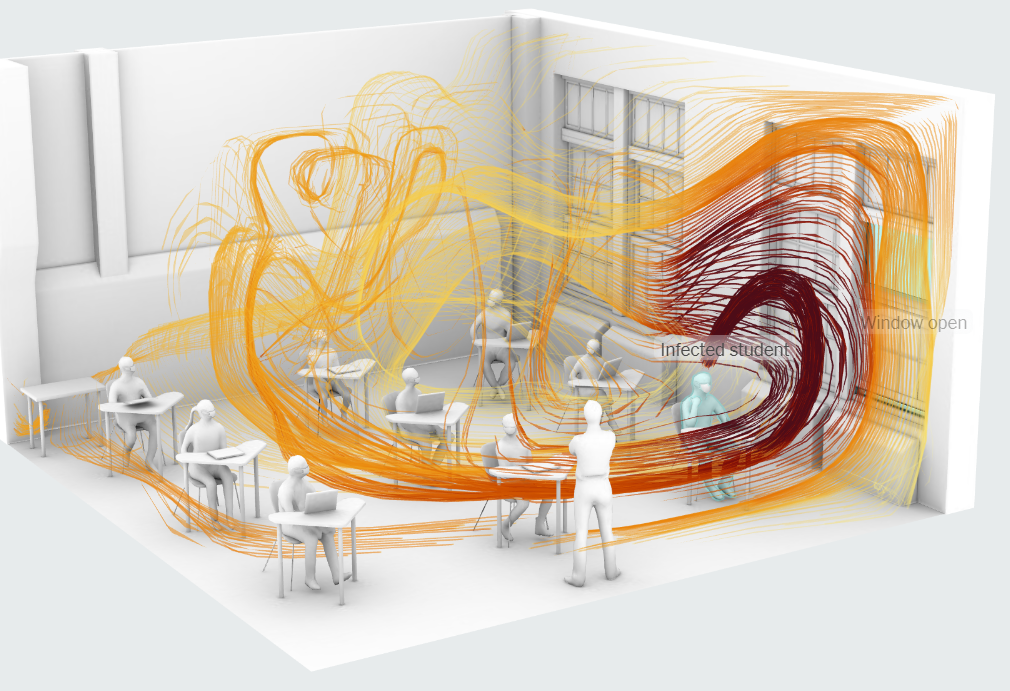

No one wants schools to go back to normal more than parents and teachers. Due to COVID-19, most schools and universities closed and went to online teaching due to outbreaks. Some schools are still in an online format because of new variants, which are not optimal for teaching students. Understanding airflow in classrooms was and still is crucial for minimizing the risk of COVID transmission and allowing schools to reopen.

Jaros, Baum and Bolles (JB&B) is an engineering consulting firm. JB&B worked with the New York Times to investigate how to keep the classroom ventilated and minimize transmission. They used Simcenter Flovent to analyze classroom airflow in three scenarios – no open windows, an open window and a fan for ventilation. The results showed that opening a window helps to reduce transmission of COVID-19.

To read the full investigation, read the blog here.

Rapid ventilator design and development

Many medical device companies shifted to focus on how to fight COVID. With the indefinite delay in elective surgery, many manufacturers turned to develop rapid testing and ventilators. As a result, Medtronic designed and developed the Puritan Bennett 560 (PB560) ventilator.

The use of simulation in every stage of the ventilator’s development significantly reduced development time, enabling faster production. Medtronic utilized the comprehensive digital twin to achieve design excellence and ensure that the design could become a product. This enabled the product performance to be verified against the requirements and provided traceability. The 3D product designs were able to be rotated and exploded as required for correct construction.

To learn more about the development of the PB560 ventilator, read the white paper.

Do you want to learn more about COVID-19 and how simulation has helped fight the pandemic? Check out this blog.

Interested in other blogs about the medical device industry? Explore more here.